Hi there,

Something from ballistic tools website

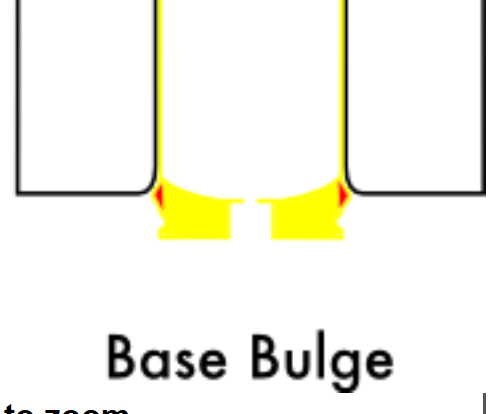

"As the illustrations show, the bottom of the die is rounded, and much of the base is in the shell plate. Most dies will only size to within about 1/4th inch of the base of the brass. If the head of the brass is expanded or flowed due to overpressure, loose chambers, or both, then a standard die, or even a "small base" die can't do anything about it. This effect, when pronounced, will often leave a visible ring on the brass near the base. The presence of a ring does not necessarily mean that the brass has flowed to the point where it will not chamber, but it is a sign that the brass has begun expanding in the section that a sizing die can't reach."

Also can you measure the shoulder bump with verniers and a spacer ( right sized tube etc) of some sort to see if it is bumping the shoulder more than it needs. It looks as if the brass is thicker under that ridge.

The edge of the die has a chamfer on it's circumference?

Good luck it looks like a sharp wee ridge somebody will know.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 15 of 15

Thread: Brass issue?

Threaded View

-

14-03-2016, 10:13 PM #9

Similar Threads

-

Scope... Issue

By Dr. Watson in forum Firearms, Optics and AccessoriesReplies: 40Last Post: 24-02-2015, 10:20 AM -

Sako a7's possible issue

By Grunta in forum Firearms, Optics and AccessoriesReplies: 11Last Post: 05-04-2014, 05:02 PM -

Issue with my gsp

By Tristan in forum Hunting DogsReplies: 6Last Post: 05-12-2013, 10:37 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

2Likes

2Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks