Hello Gents,

I recently purchased a 7mm Rem Mag Browning X-Bolt and also bought some once fired Norma brass off Trademe.

I found that the cases all had a bad bulge right in front of the belt. SAAMI spec is 13.02mm. these measure 13.25-13.30.

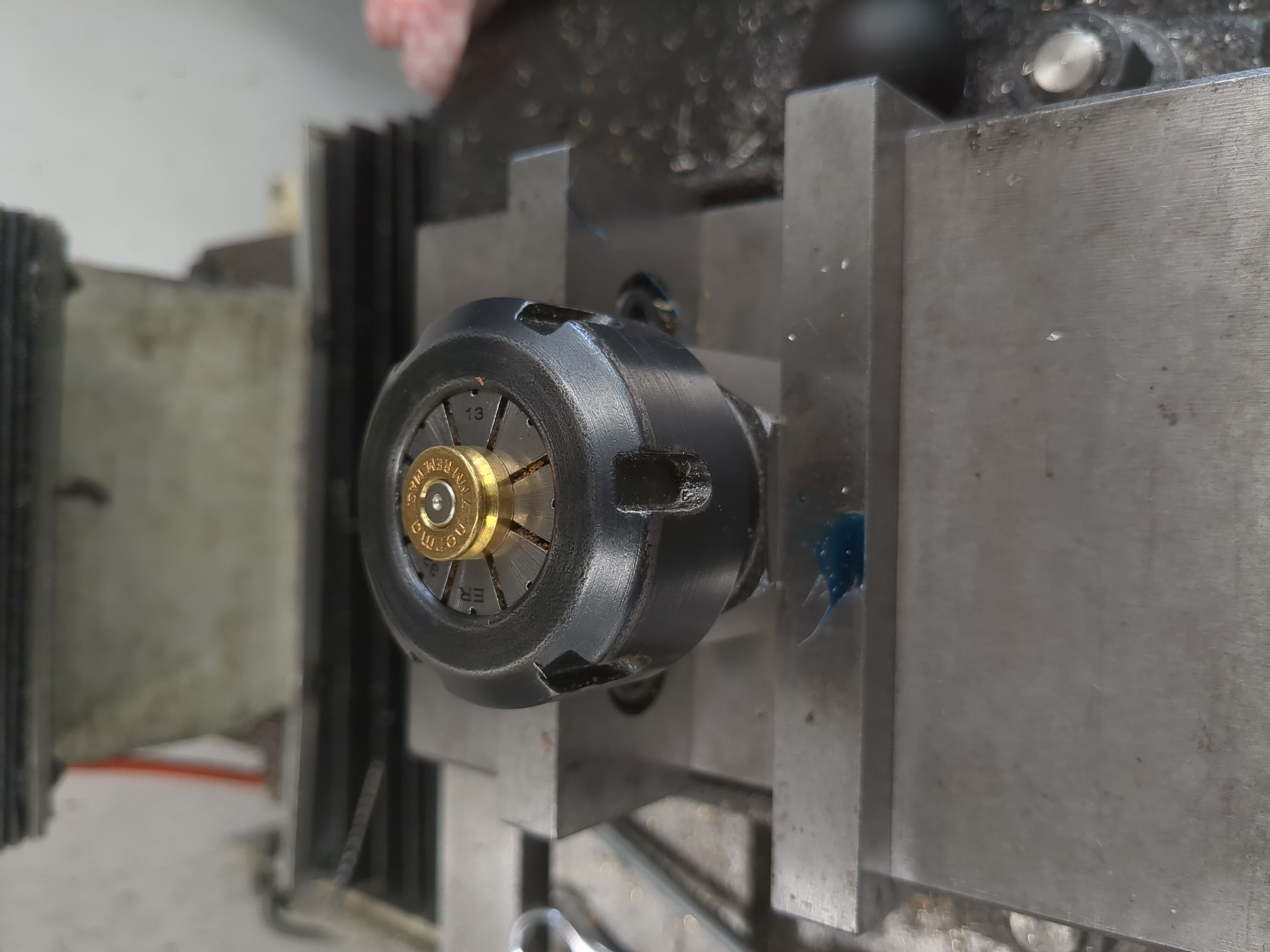

My FLS die could not deal with this and just shaved brass off and pushed it up against the belt. Not being able to get hold of one of the collet body dies (and being impatient) I decided to try squeezing the bulge out using a 13mm ER32 collet held in a collet block in my mill vice. Long story short, it works! It takes quite a bit of force, and you have to size it, the rotate it a small amount and size again to remove the lines from the collet, but after that I am able to run it through my FLS die perfectly and it chambers in my rifle.

Its not a fast method, but if you have ER collets and no collet body die, you can salvage oversized brass.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 7 of 7

-

13-04-2024, 06:05 PM #1

Fixing Belted Magnum Bulge - DIY Method

-

-

13-04-2024, 06:07 PM #2

Is that bulge not impending case-head separation?

-

13-04-2024, 06:21 PM #3Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 2,793

-

13-04-2024, 06:38 PM #4Member

- Join Date

- Jun 2013

- Location

- Middle Earth

- Posts

- 4,110

An alternative I thought about was getting a second hand 7 rm or 300 wing mag full length die and cutting off the top ( removing all the neck part from it) and turning down with a lathe bottom maybe 1 or 2 mm past the belt location . And you are just adjusting it till it resizes that bulge with out touching the neck. The neck can be done separately after with a normal die.

-

13-04-2024, 10:10 PM #5

-

13-04-2024, 10:14 PM #6

This is what I have done. I ended up with an RCBS and Lyman FLS die, so I bored out the neck and shoulder section of the Lyman, plus shortened the base a little. Now I can size hard up against the belt and the shoulders are not pushed back at all. This is handled by the RCBS die, which has been shimmed to provide about 0.02" of shoulder bump from what my rifle will close on. Lots of steps.

-

13-04-2024, 10:18 PM #7Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 4,055

Yep, originally I think it was there to set the headspacing on the old straight walled big bore cartridges. Nowadays on bottleneck cases it's a hangover that creates more problems than benefits, as most still set the cases up to headspace off the shoulder. I never thought about setting up the ER collets to squeeze the bulge down, nifty. Probably never have to do it now haha. I've only ever used the collets to nick old crimped in berdan primers out...

Similar Threads

-

Fixing bulge in front of the belt on my rem mag brass.

By Fisherman in forum Reloading and BallisticsReplies: 2Last Post: 27-08-2021, 07:36 PM -

Has anyone ever run tests on a belted magnum collet resizing die (before and after)

By T.FOYE in forum Reloading and BallisticsReplies: 14Last Post: 05-01-2021, 03:27 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

2Likes

2Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks