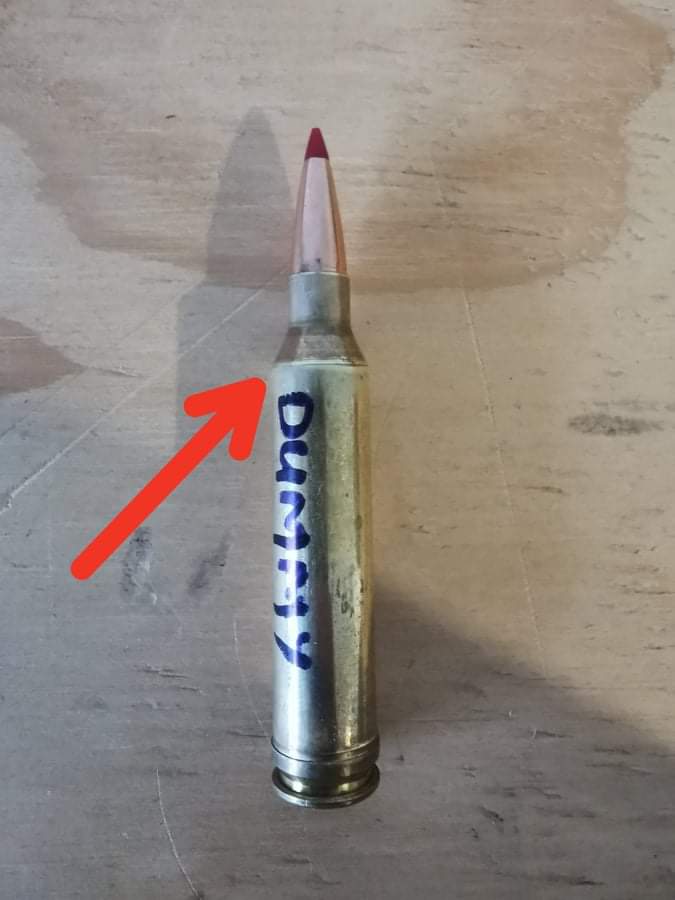

I'm relatively new to reloading, only been doing it about 1 year. I have a Lee 4 die set and Hornady press. When trying to full length resize Hornady brass the case comes out with quite a sharp edge as shown in pictures rather then a rolled edge as comes factory. Has has anyone else experienced this or am I doing something wrong? Any suggestions to resolve this? Neck sizing is sweet, no issues at all.

Nick

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 25

-

15-06-2021, 12:46 PM #1Member

- Join Date

- Jan 2012

- Location

- Taupo

- Posts

- 675

Full length resizing 7mm Rem Mag problem

-

-

15-06-2021, 01:59 PM #2Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,494

Normal. When the brass is formed at the factory, that body-shoulder junction is going to be a little rounded. When you fire it, it'll pop out and form to the inside of the chamber (mostly). This is a perfectly good thing. Your sizing die may even sharpen the bend up even further when you run it through. Again, this isn't a bad thing.

If it chambers, you're good to go. Next, read up on shoulder bumping and try and set up the die to only bump 0.002".Resident 6.5 Grendel aficionado.

-

15-06-2021, 02:11 PM #3Member

- Join Date

- Aug 2014

- Location

- Palmerston North

- Posts

- 911

Can you catch the sharp edge with your fingernail? If so id hazard a guess that your die has some form of manufacturing defect. Pull it apart give it a clean, send a scribe or anything pointy up the die body to see if theres a sharp edge it can catch on.

-

15-06-2021, 02:13 PM #4Member

- Join Date

- Dec 2018

- Location

- Christchurch

- Posts

- 449

Is that a very minute spilt or ripple right on the shoulder Junction? If it isn't smooth all the way around there might be a problem.

Sent from my SM-G975F using TapatalkUbique.

Once divided, always conquered.

-

15-06-2021, 02:40 PM #5Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 2,712

Greetings Nick.m,

I suspect you are over sizing your cases. This is likely to happen if you set your die down hard on the shell holder. See Pommy's post about shoulder bumping above. Belted cases are tricky to resize. Serious reading is required.

Regards Grandpamac.

-

15-06-2021, 04:26 PM #6Member

- Join Date

- Jan 2018

- Location

- New Zealand

- Posts

- 778

I agree with @grandpamac

Back the sizing die out a bit. Set it so its hardly touching the shoulder.

Its generally thought that best practice when sizing belted magnums is to neck size only. This causes the fired cases to headspace off the shoulder and not the belt. (you can do it will a full length sizing die, or a specific neck sizing die)

So basically you want to be resizing it as little as possible. Enough that it will chamber correctly and that the neck can hold a projectile properly and no more.

Can you wind the die out a bit and still have it chamber OK? If so - do that. Keep winding it out so that it sizes the whole neck but doesn't really touch the shoulder. Or you can use a neck size only die.

-

15-06-2021, 04:48 PM #7Member

- Join Date

- Nov 2020

- Location

- Auckland

- Posts

- 584

I would agree totally

With belted mags you need a comparator attachment for your digital calipers (such as the hornady system) to take the real fired shoulder to head (base) reading. That can be up to 6thou longer than factory/unfired i've found.

The main thing is that you want your reloads to fit slightly bumped but engaged at the shoulder. So take off .002". You don't want to knock it all the way back .006" or it will return to indexing off the belt (which is not so great).

Dont know about sharp edges tho sorry. I use imperial wax outside and graphite inside, have never had my shoulders come out sharp from rcbs, hornady, redding or forster. Lee, well lets just say i hate my 45-70 dies. Scratchy.

p.s This is where having access to a modern annealer will help. I can usually get the shoulders to within .0005" after induction annealing (amp)

-

15-06-2021, 06:03 PM #8Member

- Join Date

- Jan 2012

- Location

- Taupo

- Posts

- 675

Thanks for the replies. Little bit to get my head around, but think I'm making inroads. Pulled the die apart, degreased it and checked it, all seemed to look OK. Also no splitting I have the brass it's just the picture.

Then went and found a handful of remington and Norma brass I'm not using and tweaked the die up and down ever so slightly.

What I found was that if I wound the die in a little more (solif half turn past where the die and shell holder touch) it rounded the edge over more and had less of a sharp lip. Also found if I backed it off a bit I would also minimise this sharp lip.

So as has been suggested it seems I need to get a comparator and find the difference between the fired and factory and then adjust from there.

-

15-06-2021, 06:56 PM #9Member

- Join Date

- Jun 2019

- Location

- Tasman

- Posts

- 506

Try just using your rifle’s chamber as a comparator. Bump the shoulder until you get just a slight amount of resistance when closing the bolt. Too much and you will be head spacing off the belt again, which is not ideal as mentioned above.

-

15-06-2021, 09:25 PM #10

so you fellas are talking about ....partial length resizing...... use your FLR die,but DONT SCREW IT RIGHT DOWN... you back it out half a turn instead of screwing in further half a turn...and go in little bits of a turn from there....

you will see how much/little of neck has been squished down/resized and the body of case will be moved only a little bit,try in chamber till you just feel slight resistance.

-

15-06-2021, 09:53 PM #11Member

- Join Date

- Mar 2016

- Location

- Waikato

- Posts

- 403

Where are you based? If you’re local I could pop over with a comparator and help you get set up.

-

16-06-2021, 08:36 AM #12

All this talk about setting up your die to set the shoulder back two thou has been debunked in an interveiw with the vice president of redding explaining why you should be using competition shell holders.

I have had a set for years for doing 308 sized cartridges which is all the common ones including the 30-06 line of cartridges.

I seem to use the 6 thou one the most.

The other thing to be really carefull of is to only use the same brand of shell holder with the dies.

This i found out the hardway by mismatching and rendering a heap of good brass to the bin when I started getting case separations from it been oversized.

I will try to find the link to the pod cast as its bloody interesting.

I even bought another set for my 300 norma mag, not cheap but by far the best option for achieving correct head spaced brass.

Just saying

Sent from my SM-A025F using TapatalkMy favorite sentences i like to hear are - I suppose so. and Send It!

-

16-06-2021, 09:03 AM #13Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 2,712

Greetings again Nick.m,

I just had a quick read through the replies and noted that no one had mentioned the reason we avoid over sizing, especially in belted cases. When an over sized case is fired it gets shunted up the front of the chamber by a combination of the firing pin strike and the primer going off. As pressure builds the case stretches until the case base meets the bolt face. All this stretching occurs not far in front of the belt which thins the case at that point. After as little as three or so loads (depending on the amount of head space present) the case can crack when fired leaving the front half of the case in the chamber, something to be avoided. Sizing the cases just enough to chamber, minimum shoulder bump, largely prevents this.

It is not all beer and skittles however. The minimal sizing leaves a section of the case in front of the belt unsupported. Depending on the case make and rifle chamber, after a number of loads, this section of the case can stretch to the point that the case chambers hard, a problem that can persist even after full length resizing with the die hard down on the shell holder. There is a special die available to fix this should it occur. This problem does not occur with every rifle but can be hard to spot if you don't know about it.

Handloading is a permanent state of ongoing learning. Welcome.

Regards Grandpamac.

-

16-06-2021, 09:15 AM #14Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,494

Sounds a bit spurious. Almost like they're trying to get you to buy their shell holders. Whether you adjust the height of the die or use a different shell holder to adjust the height of the case, surely the end result is that the case gets shoved the same amount into the die, no?

The standard plate height is meant to be 0.125" though sticking with only one shell holder is not a bad idea, since you cannot trust that they'll all be exact.Resident 6.5 Grendel aficionado.

-

16-06-2021, 09:45 AM #15Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 2,712

Greetings Pommy,

Andyanimal31 is right. The Redding Competition shell holder sets are top of the heap for keeping on top of head space issues. I still neck size for a lot of my handloading but my son uses the Redding Competition shell holders and full length resizing for his FTR and FO rifles. This seems to be the current standard. Only the cost has prevented me taking the plunge to date. I would need 4 sets but should start with some for my 6.5x55 rifles.

Regards Grandpamac.

Similar Threads

-

How to measure cartridge heradspace length and assess your resizing.

By Bagheera in forum Reloading and BallisticsReplies: 1Last Post: 13-08-2019, 01:55 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks