My step son is at uni in AK and has been working for a company that does electron beam additive manufacturing (titanium 3D printing). They make parts for aerospace, F1, medical (body) parts and Americas cup boats.

Thinking that sounded kind of interesting I sent him a T3 bolt shroud, which he scanned and then made some changes to, and this is the result.

The texture is interesting (and can be changed but I kind of like this, being a bit different) and I don't have a confirmed price yet. It may change with the numbers produced.

I was wondering if anyone would be interested in buying one if I got a couple done and what sort of money people would pay for one.

Also if there are any other parts that people think would be likely candidates for this sort of treatment let me know.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 20

Thread: Expressions of interest

-

01-03-2018, 06:50 PM #1

Expressions of interest

Experience. What you get just after you needed it.

-

-

01-03-2018, 06:53 PM #2Member

- Join Date

- Aug 2012

- Location

- Christchurch

- Posts

- 4,467

Bottom metal/plastic

-

01-03-2018, 06:59 PM #3

a trigger guard/frame for my mossberg 500...

Use enough gun

-

01-03-2018, 07:07 PM #4

Maybe I should have left the last sentence off the OP.

Experience. What you get just after you needed it.

-

01-03-2018, 07:12 PM #5Member

- Join Date

- Nov 2013

- Location

- Papamoa Beach

- Posts

- 2,755

So many applications, how awesome, the list could get quite large and the bill lol

-

01-03-2018, 07:50 PM #6

AR15 lower.

Welcome to Sako club.

Welcome to Sako club.

-

01-03-2018, 07:57 PM #7Gone but not forgotten

- Join Date

- Apr 2017

- Location

- Hamilton

- Posts

- 4,129

It moved your bolt handle to the wrong side, I'd ask for your money back!

-

01-03-2018, 08:31 PM #8Member

- Join Date

- Feb 2016

- Location

- Stewart island / canterbury

- Posts

- 9,186

-

01-03-2018, 09:01 PM #9Member

- Join Date

- Jun 2015

- Location

- Hamilton

- Posts

- 1,195

Savage bottom metal..

-

01-03-2018, 09:25 PM #10

The list will be almost endless. parts runs for BSA's might be an option and tikka bolts with the amount of quiries on forums.

-

01-03-2018, 10:08 PM #11Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,225

Be aware that electron beam/laser 3D printed metal is not as strong as normal machined metal of the same grade. With some metals the 3D printed item is only rated at about 50% of the strength of conventional machined metal. Something like a bolt shroud or trigger guard is OK because they are not pressure-bearing items. It is usually much cheaper and stronger to have parts made by conventional machining from bar stock. One-off items are much cheaper to make on ordinary mills, lathes, etc. than would be the case for CNC machining. A good tradesman with a properly dimensioned freehand sketch could make some parts on conventional machines in less time than it takes for the CAD drawings and tool setting to be done for the CNC machine. Using a 3D printer to make PLA patterns for investment casting would be preferable for many items (a process I use myself for some tricky items).

-

02-03-2018, 06:37 AM #12

Fishing Jigs that work on Snapper

Rule 7: Avoid alcohol and drugs when handling firearms

Rule 7: Avoid alcohol and drugs when handling firearms

-

02-03-2018, 08:07 AM #13

Already have some of those @Munsey. It's the fisherman that doesn't work.

Experience. What you get just after you needed it.

Experience. What you get just after you needed it.

-

02-03-2018, 08:23 AM #14

I think this depends on the process. They use varying degrees of current for different applications and claim twice the strength and half the weight of machined stainless steel. Should be strong enough for most firearms applications especially small complicated parts.

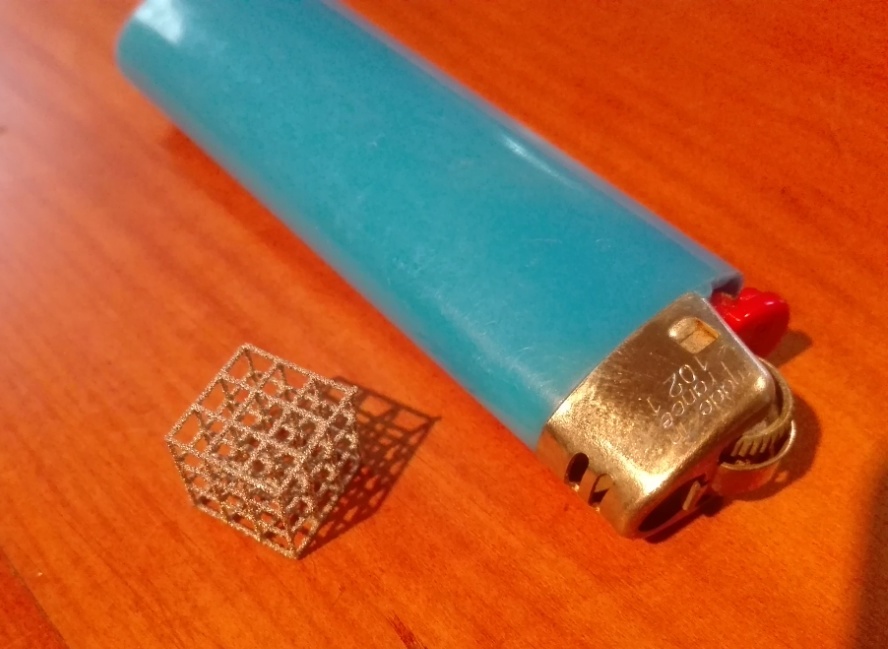

This is a 1cm cube with 0.4mm thick structure.

Last edited by Shearer; 02-03-2018 at 08:38 AM.

Experience. What you get just after you needed it.

-

02-03-2018, 08:33 AM #15

Would be intresting to see the metalurgical report on the stuff.

Similar Threads

-

Expressions of interest; Pointer for sale

By moonhunt in forum Trial, Pedigree and Bird DogsReplies: 17Last Post: 04-03-2013, 05:22 PM -

Expressions of interest for a Wellington Reloading and Scope ring lapping 'Workshop'

By Spanners in forum Reloading and BallisticsReplies: 13Last Post: 13-08-2012, 12:09 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

20Likes

20Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks