Hey, just thought I'd give a bit of an update with how I've got on here after asking for advice on another thread. Keep in mind I'm very much an amateur and I'm making this up and learning by doing.

Anyway I'll give you a brief background/how I ended up here.

I've always been able to keep any knives I have had sharp with the following 2x steels - a diamond jewelstik and a descend steel and when things got really bad/fkd, I've got a very cheap norten oilstone.

I found my kitchen and cheap hunting knives (like below) were easily maintained/sharpened to sharp enough to shave my arm hair with these two.

However with recently acquired higher quality steel these would no longer cut it.

After my recent thread and some internal battling I settled on buying a decent 240/1000 grit waterstone and I've got to say I'm impressed.

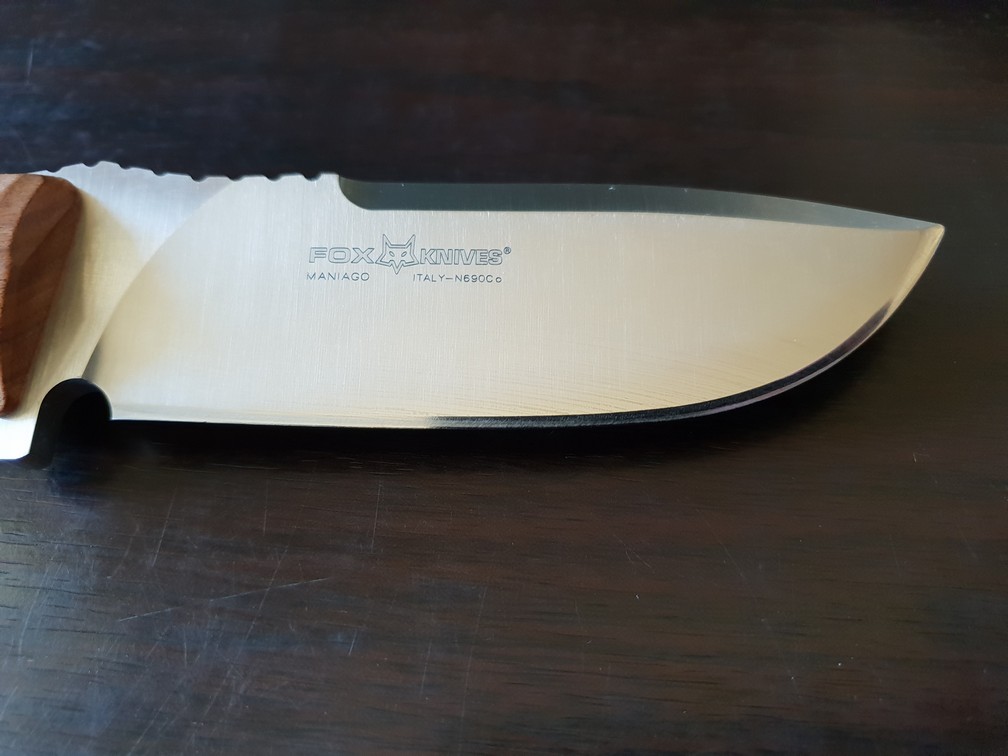

This knife-

Had a very step grind on it and I found the belly very hard to resharpen. After a good 3/4hr work on the 240 grit, I manged to get what I think I need shape wise - a lot of material came off - particularly near the tip.

Then 15-20 mins on the 1000grit to fine it out a bit and I was actually happy with it!

However I still found I could get it sharper with the diamond steel and steel though which is what some of the coarser looking marks on the edge are.

Finally I gave the strop/compound(autosol) option I final go. Actually had some success. Using these....Don't laugh, yes there are cut off an old bridle....

These definitely helped fine the edge out and got this steel v sharp. I think harder steel responded better to this than the softer steel I originally tried.

I'll guess I'll wrap this up. I managed to achieve results without having to spend big $$$ on a scary sharp or the like. Also now that the bulk of the work has been done, hopefully I should only having to maintain instead of resharpen so the time that went into this should be well spent.

Big thanks to all that gave advice etc.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 11 of 11

Threaded View

-

22-01-2019, 07:56 PM #1

Japanese Stone Knive Sharpeneing Update - Pic Heavy

Last edited by suthy; 22-01-2019 at 08:18 PM.

Similar Threads

-

Gun City Japanese Arisaka type 38s

By Burb122 in forum Firearms, Optics and AccessoriesReplies: 73Last Post: 04-11-2018, 07:30 PM -

Travelling Stone (Another short story)

By Dougie in forum The MagazineReplies: 11Last Post: 14-08-2013, 05:56 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

10Likes

10Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks