Crappy photos as its raining and they are taken under fluro in the workshop but you will get the idea.

Here is what we came up with for our steels. These are deliberately designed to be mounted low to the ground for range safety rules specific to our range, but you could mount them on longer uprights if you choose. Having them mounted low to the ground means that the ground spike is largely protected from stray bullets. One of the criteria we set for the design was for it to be low maintenance.

Ground spike is made out of 25x25x3mm MS angle iron with the vertical spikes approx 200mm long for ground penetration. The riser above the horizontal bar can be whatever length you want depending on how high you want the target off the ground.

The mounting bracket that is welded to the back of the AR500 target plate started out as a piece of 35x35x4mm RHS 50mm long welded to a 50mmx3mm flat bar across the top at the correct length to give the RHS a 20 deg angle to the target plate. From this prototype we then got some brackets laser cut and folded to better support the RHS and give a greater weld area and hence strength. The bracket closes off the top of the RHS so that the vertical riser on the angle iron ground spike cannot pass through.

When mounted on the spike, the target cannot rotate and will not bounce, will not come off the stake but has enough movement to allow impact energy to dissipate and to provide a degree of 'ring' on impact.

These have withstood close range impacts with a 50AE and it didn't shake the spike out of the ground. We have come up with an additional spreader bar that can go over the vertical riser on the ground spike before the target plate is fitted to provide extra recoils resistance but it has never been needed.

The laser cut brackets work very well and are ideal when making up larger numbers of targets but aren't necessary if you are only making a couple of plates - box section and flat bare will work.

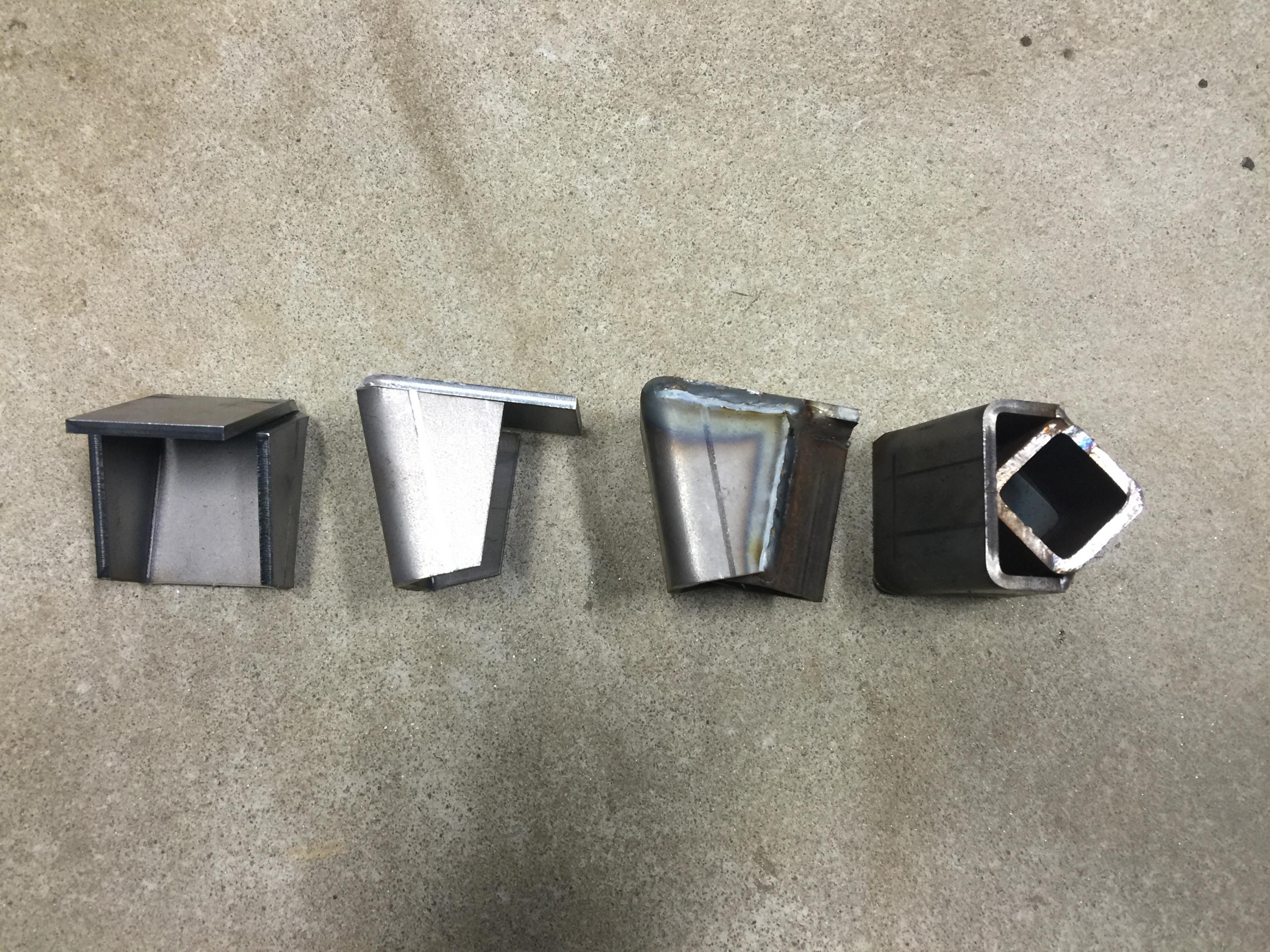

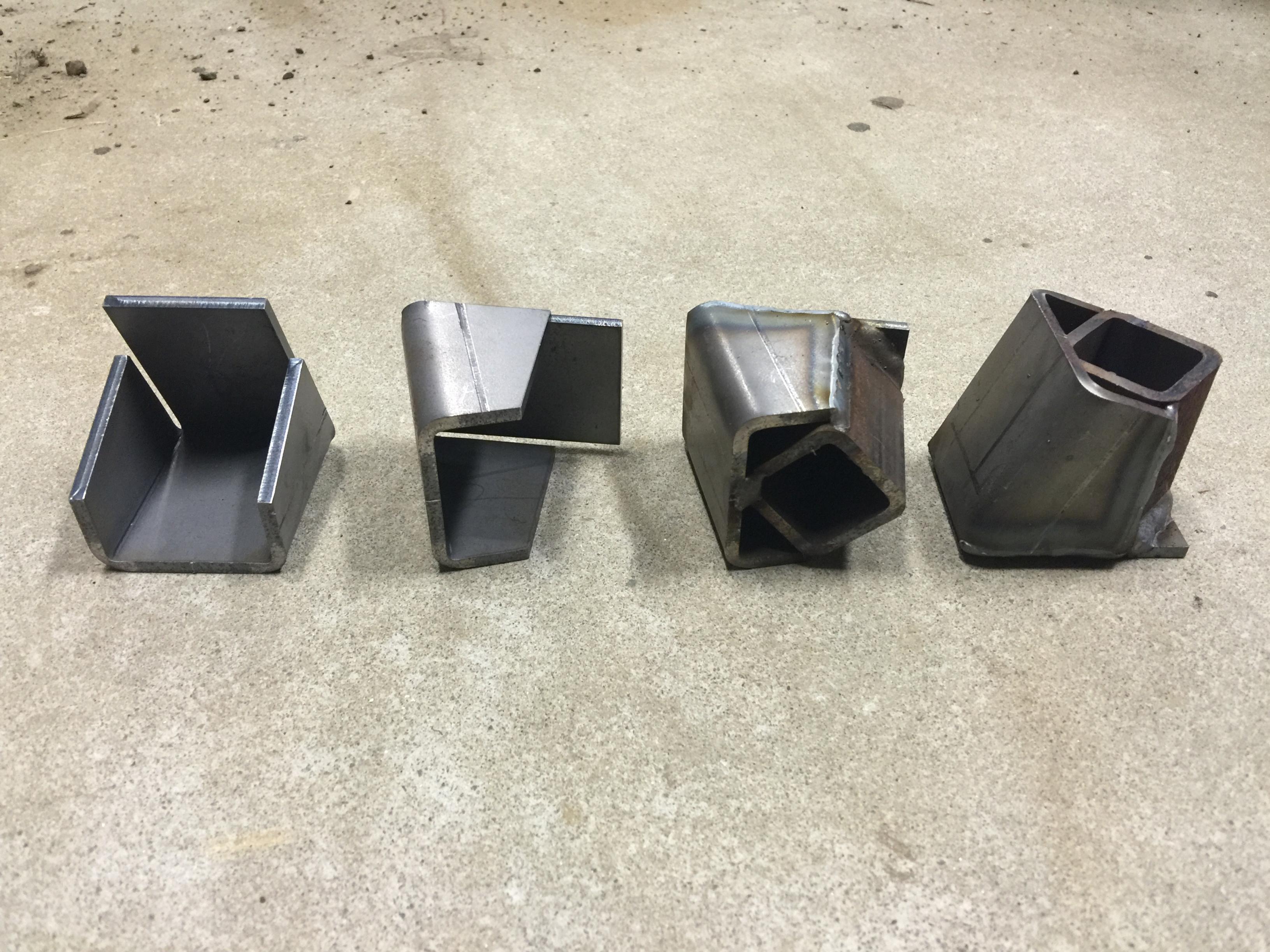

Images showing the shape of the laser cut bracket and the welded assembly with the 35x35x4 RHS welding in place.

Close ups of bracket assembly.

Bracket welded in place on the back of the target, giving a 20 deg mounting point.

Ground spike and ground spike with target plate mounted. If you look closely, you can see a lead line on the ground spike just below the target plate matching the plate angle, resulting from the bullet splatter. There is no damage to the ground spike unless you hit it directly with a bullet. In service, after 20 rounds, you will find a 1-1.5m long trench form under the target plate where the bullet splatter has been directed down to the ground by the 20 deg plate angle.

Hope this helps.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 66

Hybrid View

-

30-06-2016, 07:09 PM #1

Last edited by hotbarrels; 30-06-2016 at 07:16 PM.

Similar Threads

-

gongs

By Pengy in forum ShootingReplies: 10Last Post: 06-10-2015, 02:44 PM -

Any one want any Gongs?

By Blaser in forum ShootingReplies: 30Last Post: 29-01-2015, 07:27 AM -

.22 gongs

By big_foot in forum ShootingReplies: 26Last Post: 25-04-2014, 03:05 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

42Likes

42Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks