Some pics to show what I'm talking about.

You can just see the faintest mark on the shoulder, no other marks anywhere on the chambered case

Pics of case measurements

The case coloured in black has now been full length sized in my Lee sizing and decapping die twice and is still way to tight, its got me stumped.

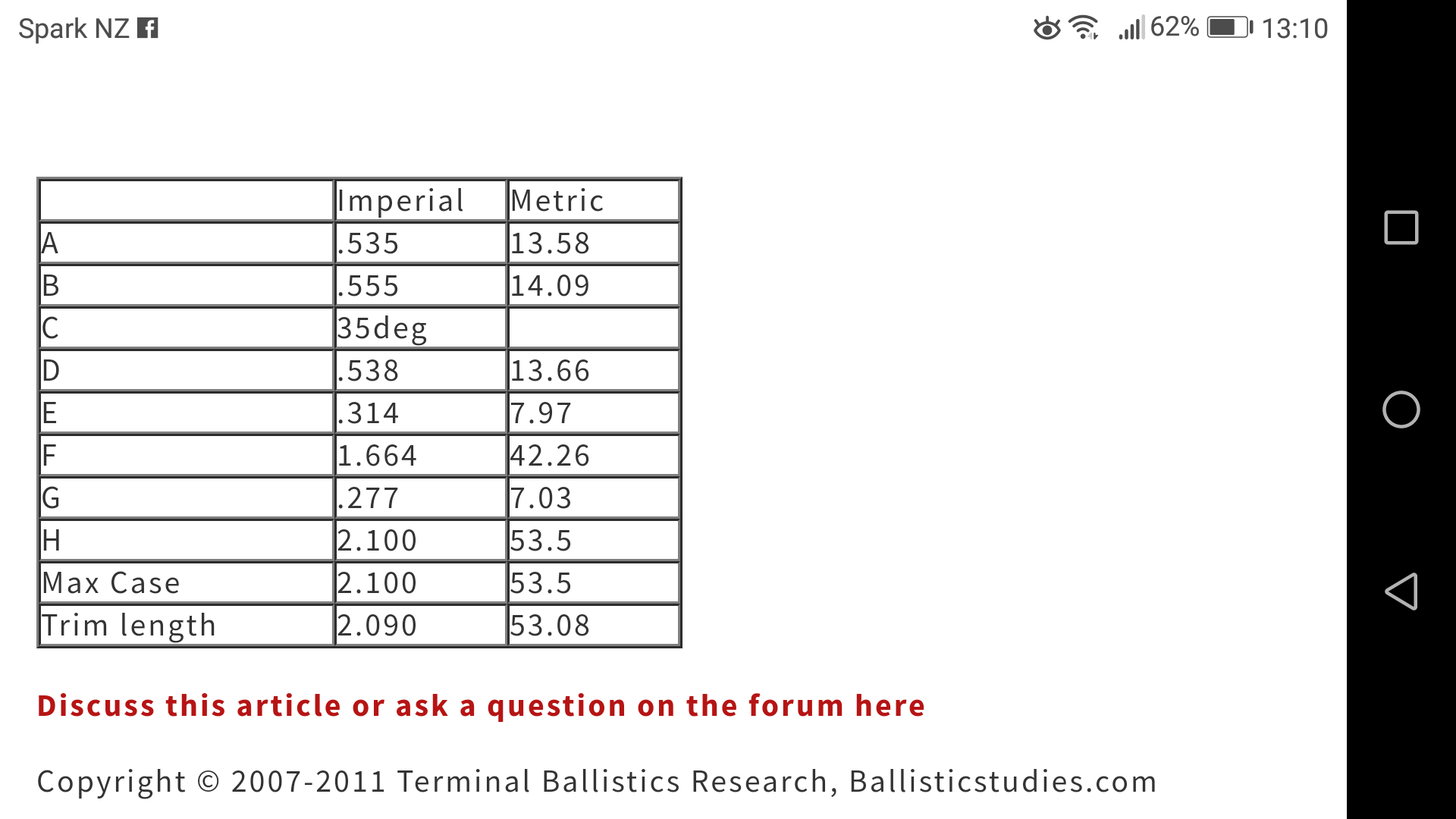

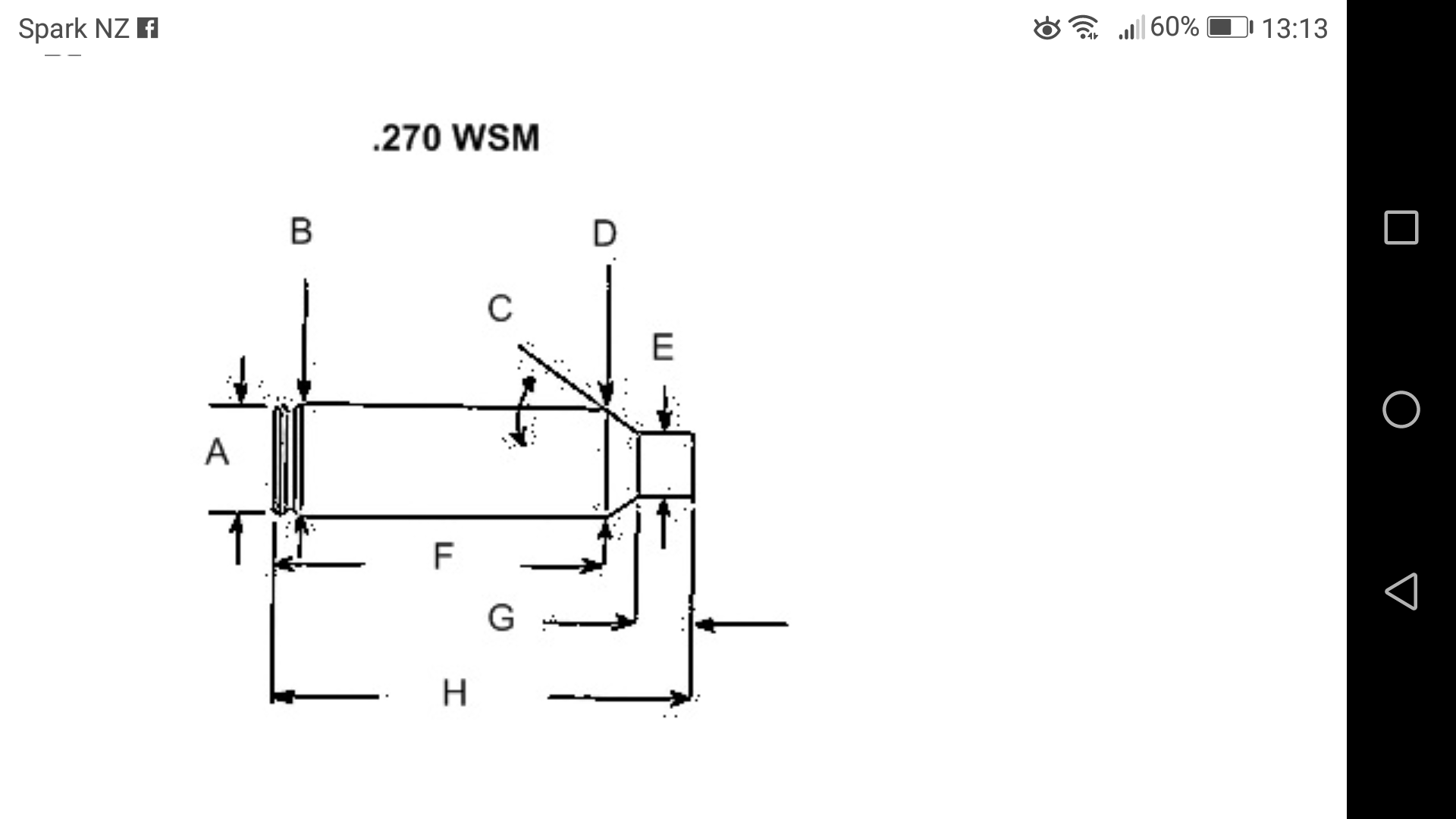

Below is a chart showing case dimensions note the full length trim and max measurements and the "F" measurement which is base to shoulder

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 30 of 59

-

30-07-2019, 02:12 PM #16

-

-

30-07-2019, 02:22 PM #17

The only thing I can think of is that maybe the head space in my chamber has much tighter tolerance than the rifle this round was originally fired in and no matter how much I try and re size it, it's never gone be right in my chamber due to the cartridge springing back a little once it's been through the die ?

I can't otherwise see how my head space could have shrunk ?

-

30-07-2019, 04:41 PM #18

Have just checked the width at the shoulder or "G" on the chart and it's 13.7mm could this mean my theory is correct and the rifle this cartridge was originally fired out of has fireformed this case bigger than what I can size it back to ?

-

30-07-2019, 05:13 PM #19

Have you trimmed them at all @dannyb

That bottom pic measurement looks quite long compared to the trim length on the chart

-

30-07-2019, 05:33 PM #20

It's your sizing die setup

Flappy Disc Customs Bespoke Hunting Rifles

-

30-07-2019, 05:34 PM #21

No, I haven't. I would've thought once fired brass wouldn't need trimming straight off the bat, I can see what you mean though it's not far off maximum.

Could that seriously be all that's wrong ? Excuse my ignorance, I've not had to trim any brass yet even after 3 or 4 loads in mybold 270win.

Guess I'm buying a case trimmer tomorrow.

Out of interest could this be enough to skew my ladder test results ?

-

30-07-2019, 05:35 PM #22

-

30-07-2019, 05:35 PM #23

Message ya later, on the road...

Flappy Disc Customs Bespoke Hunting Rifles

-

30-07-2019, 05:46 PM #24

Got a big drive or something @Ryan_Songhurst?

"I heard Jesus did cocaine on a night out. Eyes wide-open, dialated, but he's fine now. And if his father ever finds out, then he'd probably knock his lights out...

"I heard Jesus did cocaine on a night out. Eyes wide-open, dialated, but he's fine now. And if his father ever finds out, then he'd probably knock his lights out...

Gets a little messy in heaven "

- Venbee

-

30-07-2019, 06:27 PM #25

You need to shoulder bump them. You might have to place a feel gauge under the case in the shell holder when you full length and cam over. This is the easiest way instead of buying shell holders with various heights, try 6 thou' and move up from there until a resized case closes correctly.

-

30-07-2019, 06:34 PM #26Member

- Join Date

- Aug 2018

- Location

- Christchurch

- Posts

- 1,785

Standard seems to be to screw in til the die touches the shell plate, lower the ram and screw in another 1/4 turn. Otherwise, mechanical play and stacking of tolerances in the press and die threads means with a case in the mix, you might not be pushing the shoulders down at all. If the press and plate touch without a case, you'll likely see a small gap when there is a case in there.

I recommend taking the expander out until you've figured it out, else repeatedly sizing the neck is just going to work harden your brass.

-

30-07-2019, 07:06 PM #27

This is exactly how I set my resizing die up, I go a half turn instead of a quarter (there's a bit of play in the cheapo lee press) but can confirm the shell holder is definitely touching the die at full extension, I think maybe first port of csl might be to buy trim die for my wuick trim and trim all the brass back to minimum trim length and check an empty case again before doing anything rash.

As has been pointed out even though only once fired it is very close to maximum length and I cant help wondering if maybe the neck is hitting the end of the chamber..... and if thst is the case (no pun intended) possibly also crimping my proectile in the process and scewing all my load testing.

Sigh......guess this kinda has turned into a cry for help

-

30-07-2019, 07:26 PM #28Member

- Join Date

- Jul 2014

- Location

- BOP

- Posts

- 4,102

Does your mate have different loading dies for his rifle. If so maybe run those tight shells through his dies and see if they will resize them to fit your chamber. If you can find a RCBS trim/form die then it will solve the problem, run them through the die trim the excess that sticks out the top of the die and job done.

-

30-07-2019, 07:31 PM #29

Mate lives way too far away for that......I'm gonna pop into gunworks and pick up a 270wsm trim die tomorrow and give that a whirl (see what I did there) it may or may not solve all my problems, although I now have the arduous task of depriming about 30 live primer cases so I can trim them

-

30-07-2019, 08:17 PM #30Member

- Join Date

- Jul 2014

- Location

- BOP

- Posts

- 4,102

The RCBS die is the only one to use. We have them in 243,308,30 06, and 300 Win and all work well.

Similar Threads

-

270WSM 130g sst vs the 145 eldx ?

By dannyb in forum Reloading and BallisticsReplies: 19Last Post: 27-05-2019, 09:37 PM -

RL26

By 25/08IMP in forum Reloading and BallisticsReplies: 3Last Post: 08-09-2018, 11:22 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

38Likes

38Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks