Started building a couple of the benches going into the reloading room aver the last couple weeks. Last weekend was dimensioning all the timber and starting to laminate the pieces all together.

This weekend started the serious business.

Plan is 4 benches/desks at about 1100mm long. Would be just two desks but the hallway and door to the room is too tight for longer desks.

Decided to use floating tenons which for the main framing.

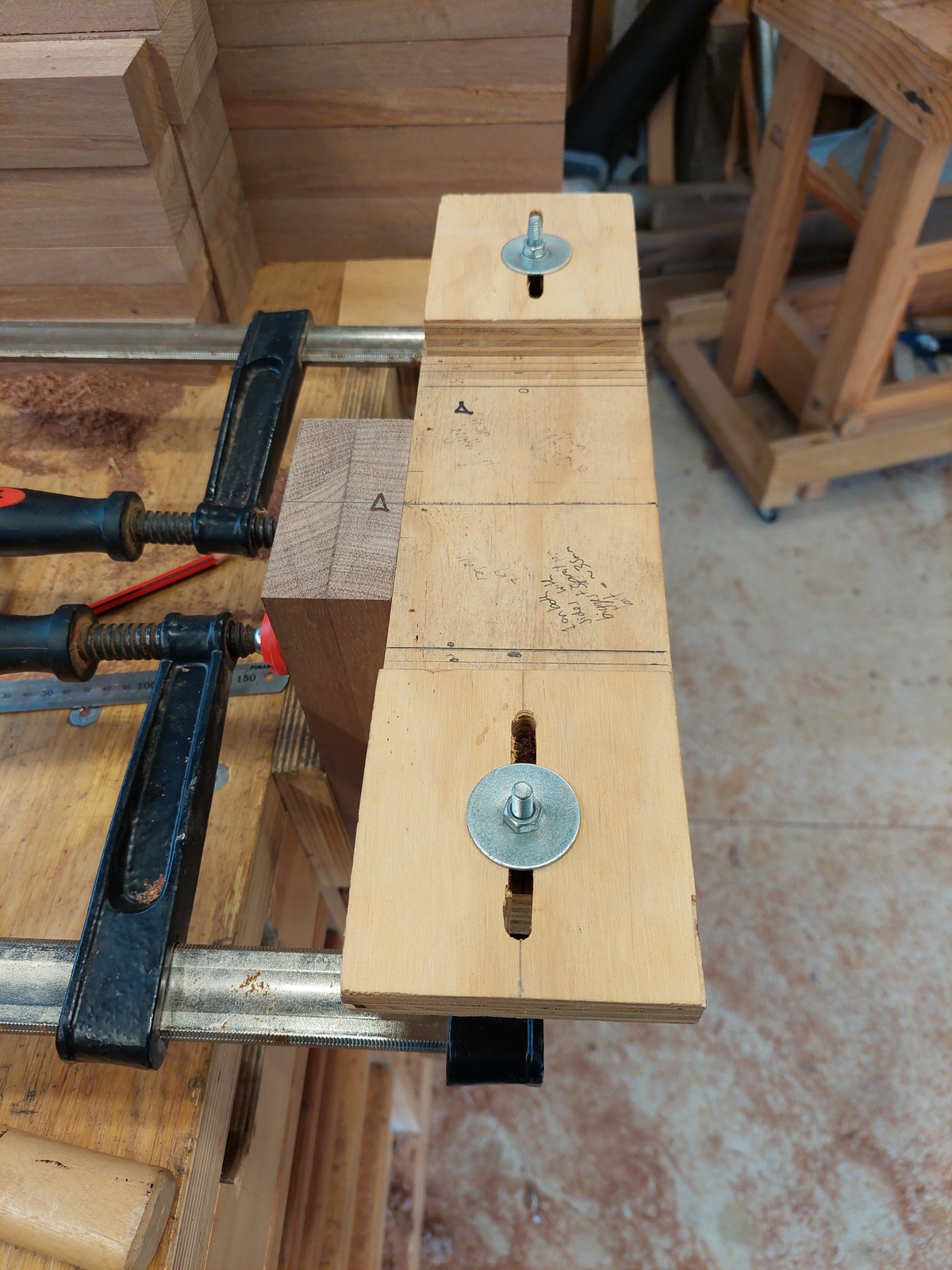

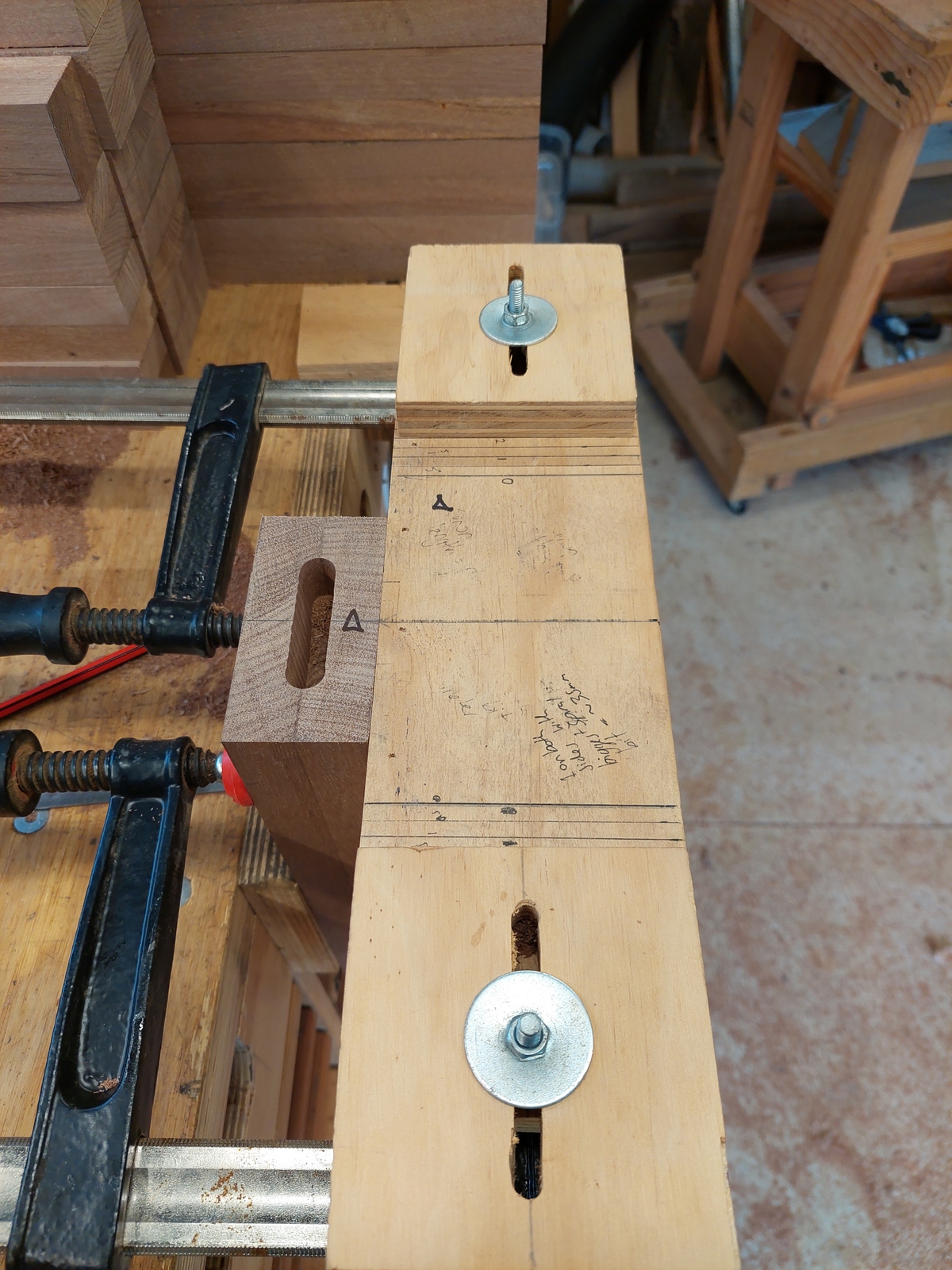

My floating tenon jig in action.

Always keep track of the side which the jig referenced off of. Always matching this face with the joining piece means it's not critical that your pocket is dead centred.

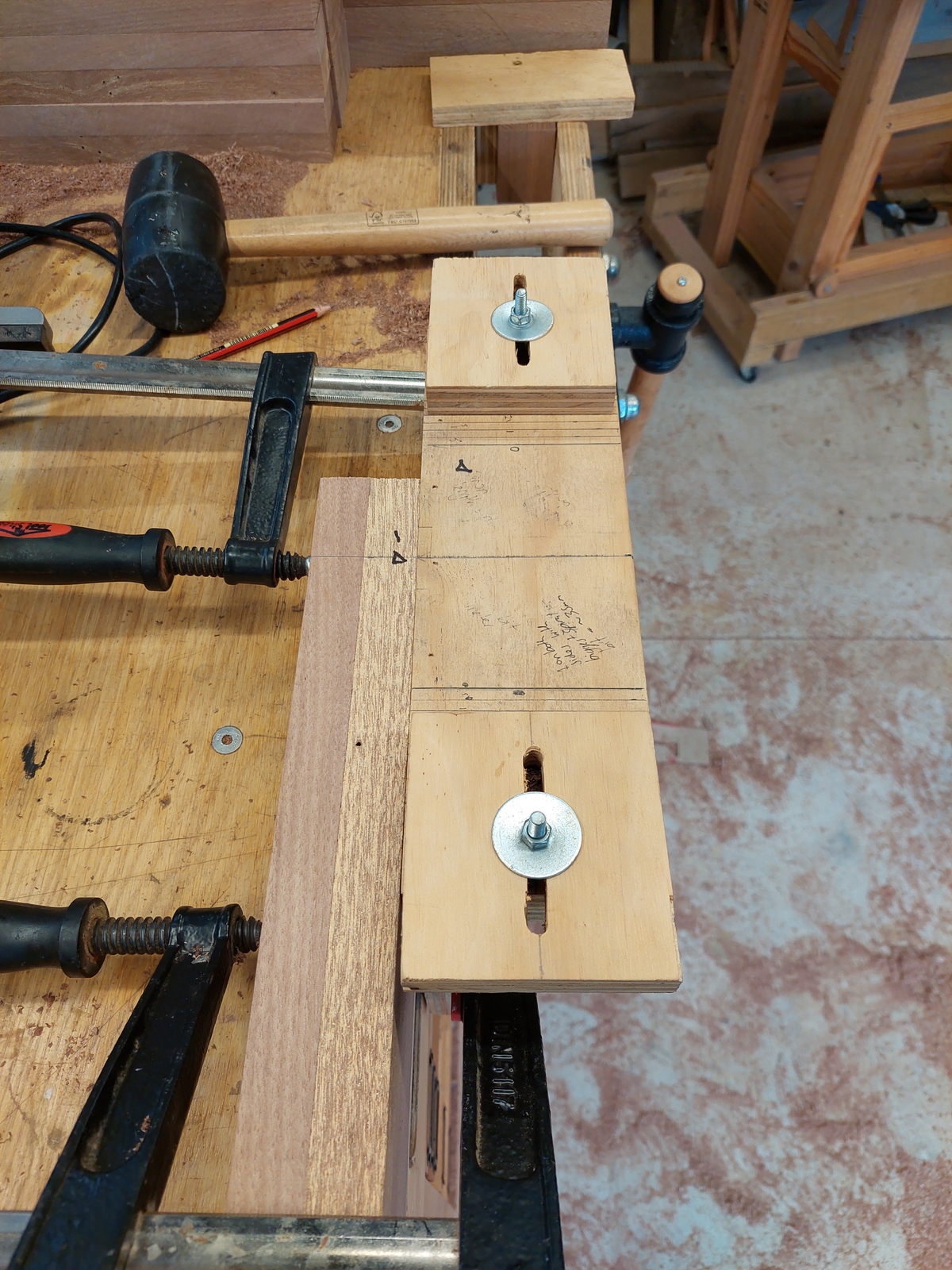

Then the legs. Note: The reference face on both ends on the parts done in above photos are all on the same side of the wood. Therefore half of the legs need to have the reference face on the opposite side so it can go together properly with matching reference facings.

Elected to do dowel joint for lower brace of legs.

Most of the joinery done.

Then I didn't have any floating tenons cut so cut a few and shaped them on the router table I knocked together 8 or 9 years ago which I keep meaning to make a better one but it just works!

I do need to buy an extra router though so I don't have to change over all the time. The Ryobi routers are bloody excellent. This one has done a lot of work over many years and shows no signs of letting up. I will buy another!

The width of the floating tenon is left a bit short for an ability to adjust them. Little to no strength is lost in doing this. Made a whole stack for stock for other projects while everything was set up. Also I didn't use the knotty bit in the photo for actual joining that was a test piece that then got turfed into the firewood pile.

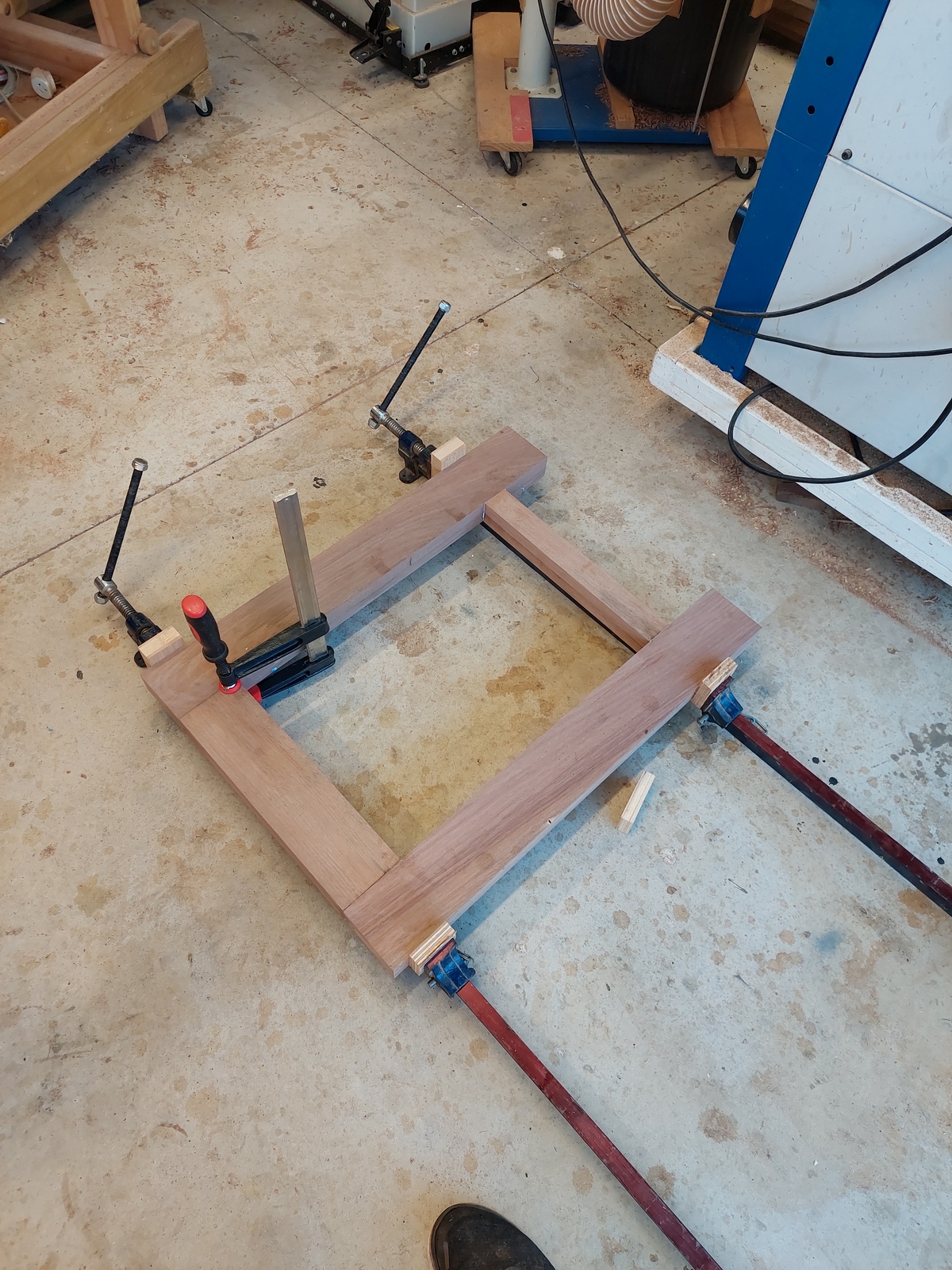

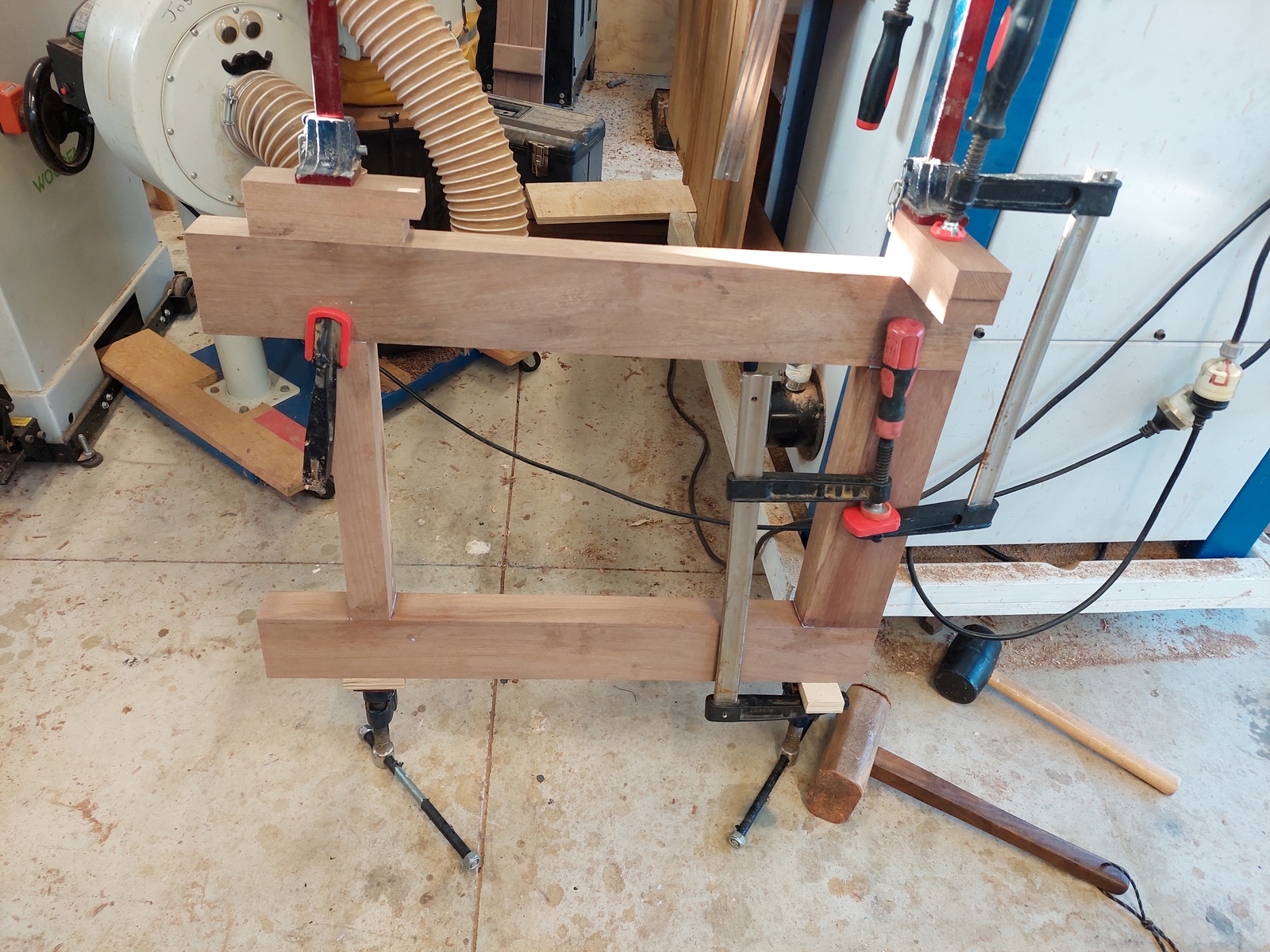

A bit of a sand on the internal faces while they're easy to get to and into the clamps.

One F-clamp there to true up a face which a twist in the wood was fighting against.

The other was having a tendency to rack/bow up out of the sash clamp so was pulled back down with some clamps. Also tagged teams to F-clamps to even out the clamping pressing on one side which was proving troublesome.

Ideally you'd have sash clamps top and bottom but I only have four and glue set is a couple of days in winter so I wanted to have two bench ends in the clamps at a time. Winter does take the stress out of glue ups though, plenty of working time.

Good thing about the two joining methods is as long as your cuts and edges are square pulling them up tight forces everything into alignment. Checked square on both sets and was happy with the result. All the dowels lined up too which is nice!

I've cut and laminated enough wood for two desks and will finish these two before doing the other two just because it's better for how much room I have in the shed to not have so many parts floating around.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 1 to 15 of 33

Threaded View

-

31-07-2022, 06:26 PM #28Member

- Join Date

- Dec 2011

- Location

- Te Awamutu

- Posts

- 1,060

Last edited by Makros; 31-07-2022 at 06:37 PM.

Similar Threads

-

Reloading equipment

By JasonW in forum Reloading and BallisticsReplies: 20Last Post: 19-03-2017, 07:57 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

42Likes

42Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks