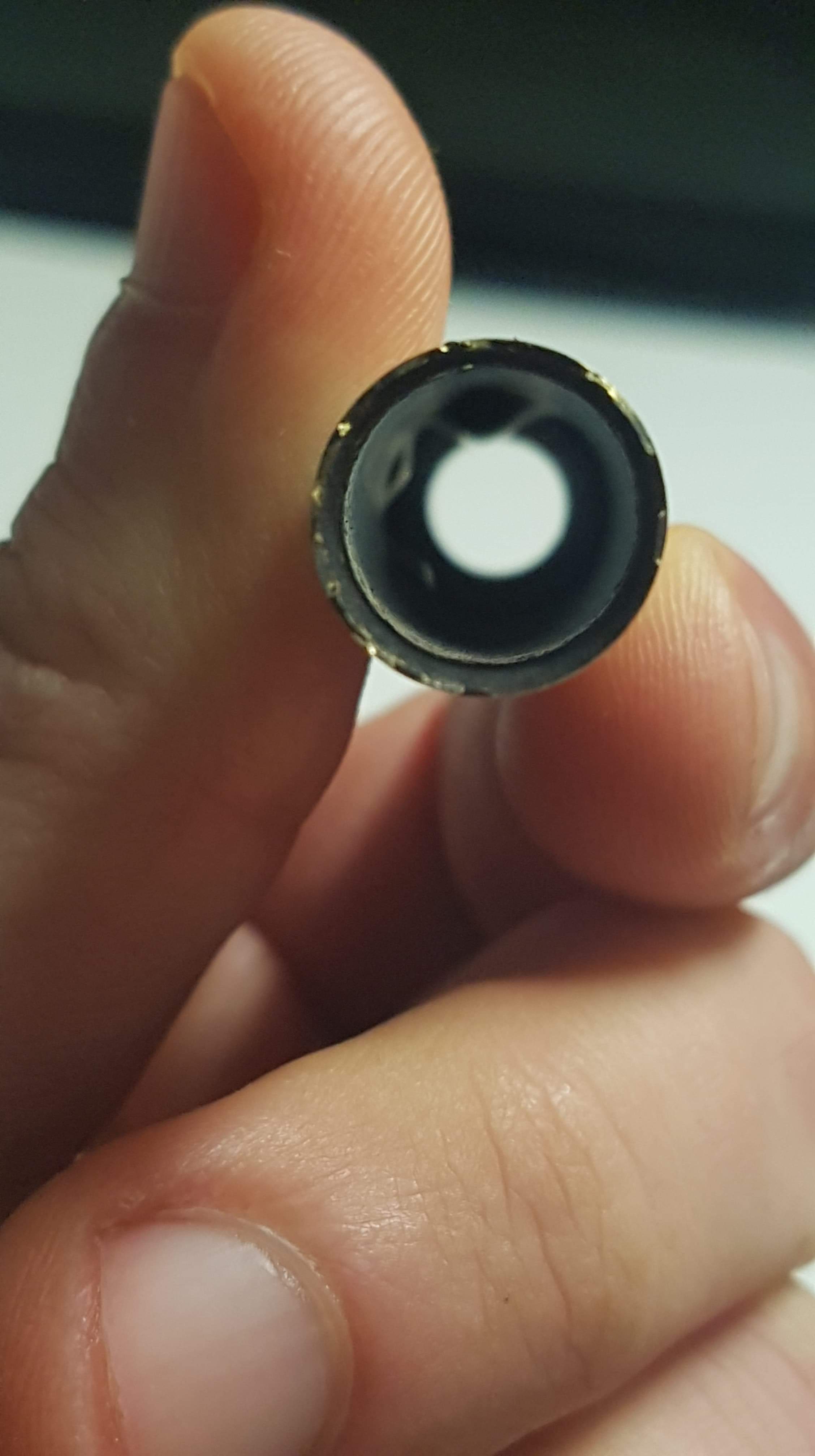

Ok team, I need the brains trust to help me out on this one. My brother was out today shooting some reloads he had made for him. Projectiles are Hornady 162 ELDX, rifle is a Sako A7 7mm rem mag.

The rifle was used by the reloader during load development and field tests.

Brass was new before load work

Any idea what could cause this?

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

Results 16 to 30 of 53

Thread: What in the world?

Threaded View

-

30-05-2020, 07:12 PM #1Member

- Join Date

- Jun 2019

- Location

- Manawatu

- Posts

- 1,422

What in the world?

Similar Threads

-

Hi there people of the world!

By nomad in forum IntroductionsReplies: 3Last Post: 25-12-2018, 05:53 AM -

New world record

By kimjon in forum HuntingReplies: 73Last Post: 10-03-2017, 10:32 PM -

Where in the world is Waimate?

By greghud in forum The MagazineReplies: 6Last Post: 19-01-2015, 07:56 AM -

New to the world

By hunter101 in forum IntroductionsReplies: 11Last Post: 12-12-2012, 12:04 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

44Likes

44Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks