Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 102

-

18-11-2022, 07:51 PM #31

-

-

18-11-2022, 10:21 PM #32Hunt safe, look after the bush & plug more pests.

The greatest invention in the history of man is beer.

The greatest invention in the history of man is beer.

https://youtu.be/2v3QrUvYj-Y

A bit more bang is better.

-

18-11-2022, 10:34 PM #33

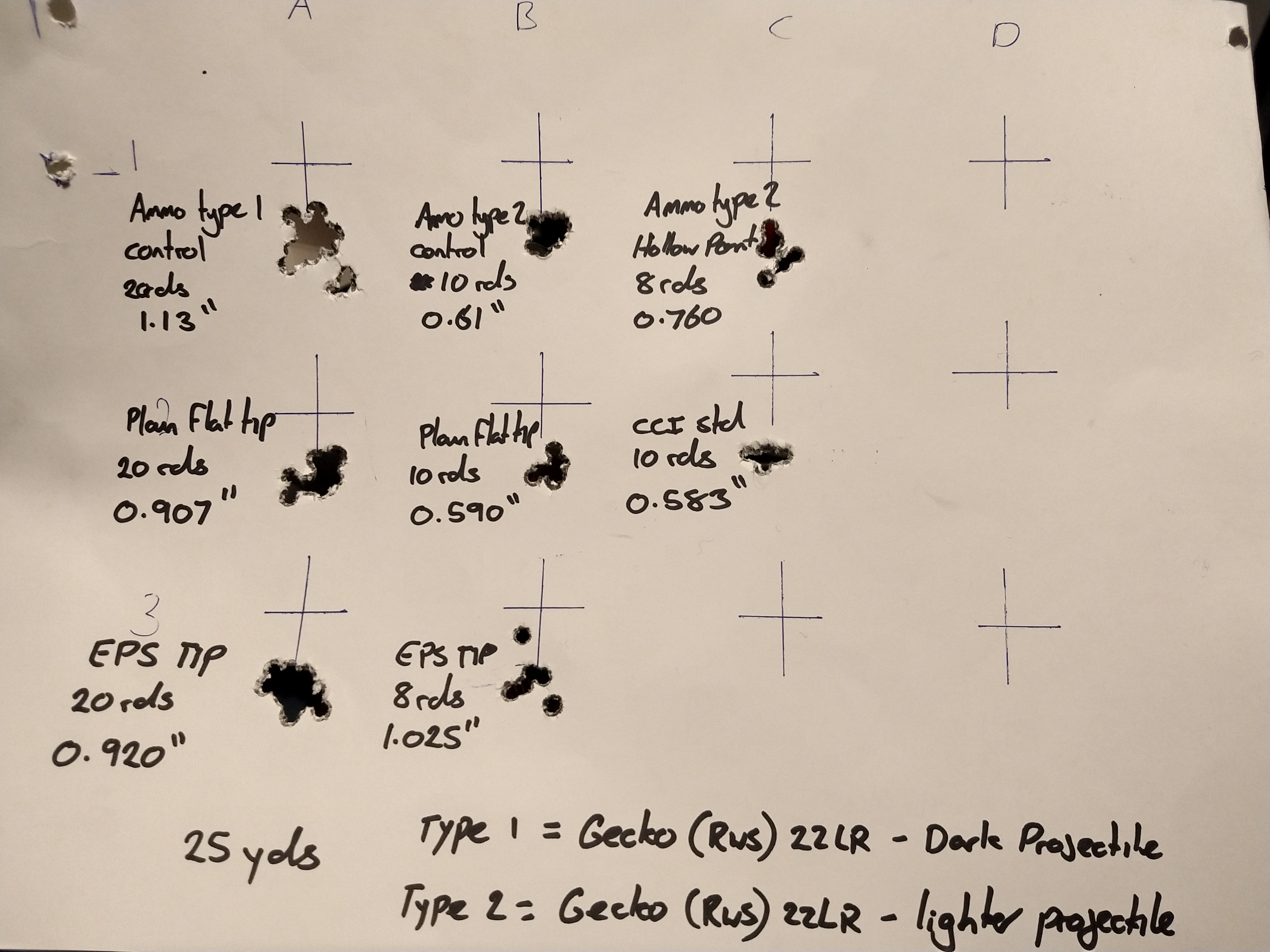

I did a little accuracy testing at 25y the other night.

The group sizes are outside measurement. All shot from a heavily modified Kriss DMK off bipod and rear bag. I dialed by scope down 1 Mrad to preserve my aim point while shooting large groups.

The gecko ammo I have 2 cases of has 2 distinctly different projectiles. One is darker, narrower with a finer nose and the other is a lighter color with a larger nose and more consistent diameter. The dark one is what I am having the most trouble with and is the one which varies widely in diameter.

I started with control groups of unmodified factory ammo, then shot a group of plain flat tip (the smallest flat I could do and still have the projectile size up correctly) and a group of the EPS tip (this is what I'm calling the Eley style flat nose with a tit)

I started with 20rd groups but was running out of time, so switched to 10rd groups for the second type of ammo.

I also ran some hollow points through but was shooting a semi and they weren't feeding correctly so a couple got munched. Same thing happened with the Type 2 EPS. Both of these had multiple damaged rounds fired into the group, so I would basically exclude them.

I shot a comparison group with CCI and this was coming off a barrel well fouled with different lube. If I ran a bore snake through and fired 20rds of CCI before shooting the group, basically all the horizontal would be gone from that group.

Long story short, there isn't the night and day difference I was hoping for with the darker projectiles, but there is a measurable improvement. I will play around with different driving band sizes and see if that changes anything. I am going out on Monday for some load development on other rifles and will take my bolt gun to test some hollow points at distance to see if they hold accuracy and whether it effects BC a measurable amount.

-

19-11-2022, 04:03 PM #34

I have tried a couple of other hollow point styles. One is a much longer but narrower tip. Interestingly, this didn't perform that well, with 2 of 5 rds completely penetrating my wet pack and going deep enough into the dirt that I couldn't fish them out without a spade. The 3 that did not over penetrate, one expanded normally and 2 partially expanded and the cavities were packed solid with wet paper.

The next one I tried is based on the federal Hydra-shok design. With a little post in the center which is supposed to reduce instances of point packing and failure to expand. I only tried 2 of these and they seemed to work fine. The cavity in the paper seemed to be larger than the others, though I did not measure anything. OD of these was around 0.36"

I'm going to try some flat and cup points as well. Any other suggestions for hollow point designs or tip shapes to try out?

-

19-11-2022, 04:09 PM #35

Here's my contribution, these are RWS Target Rifle with a 60deg conical hollowpoint (made with a dead centre for a lathe). Shot into dense wet newspaper at pointblank. As marked, they are 2.5mm hollowpoint depth, 3.0mm hollowpoint depth, unmodified solid, and a couple of factory RWS Subsonic HP rounds for comparison. All the hollowpoints penetrated about 6", the solid went about 10":

![Name: 20221119_144008[1].jpg

Views: 490

Size: 128.7 KB](https://www.nzhuntingandshooting.co.nz/attachments/f53/210615d1668827231-22lr-resizing-hollow-pointing-tool-20221119_144008%5B1%5D.jpg)

Left to right; solid, 2.5mm HP, 2.5mm HP, 3.0mm HP, Factory HP, Factory HP

![Name: 20221119_144232[1].jpg

Views: 479

Size: 103.4 KB](https://www.nzhuntingandshooting.co.nz/attachments/f53/210616d1668827267-22lr-resizing-hollow-pointing-tool-20221119_144232%5B1%5D.jpg)

-

19-11-2022, 04:30 PM #36Banned

- Join Date

- Mar 2015

- Location

- North Canterbury

- Posts

- 5,462

-

19-11-2022, 05:23 PM #37

Nice work. Your findings are largely the same as mine using a genuine Waltz tool.

One problem with wet pack testing projectiles is that the density of wet paper is way higher than any animal that you are going to be shooting with a .22LR, so take the bullet performance as a comparator only, not an absolute measure of performance. I too found that the lead harness has a massive effect on expansion, and once you reach a certain point in the size of the HP you put into the projectile, hardness has way more effect on expansion than any further increase in the size of the HP you put in with the tool.

I also saw little in the way of real-world accuracy improvement after sizing hunting grade ammo. Yes, if you are looking for the last 0.5% accuracy out of high-cost target ammo, then it is probably worth it. But, one big plus is that no ammo I put through the Waltz tool shot worse after sizing and re-HP'ing than it did out of the box.

So, the real advantage of this tool for me is that I could pick up 10,000 rounds of CCI Standard Velocity solids (which shoots well through all my guns), at a low price, and HP them for better hunting performance. The tool paid for itself in no time.

I can process a 500-round brick per hour through the tool if I put my mind to it, provided I am not re-boxing it back into the factory packets. This includes cleaning the tool after every 50-round box to remove the wax build up from inside the tool. I just drop the HP needle out and push a .22 nylon brush through the dye to clear out the wax. A failure to do this will ultimately result in a crushed round. To reduce wax build up in the tool, put the ammo in the fridge for an hour before you resize it to harden the wax.

-

19-11-2022, 06:43 PM #38Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,104

Found this, it's the newer 'in honour of' version but the profile is very similar, 40gr truncated cone with driving band mid section and rebated cupped arse. 1280fps...

-

19-11-2022, 07:11 PM #39Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,104

Don't need to be too technical here. As you have already found, a decent diameter hollow point and not too deep is the requirement the rest comes down to lead hardness. The truncated cone design with a 'driving band' configuration that is the only bit contacting the bore was what I found as the most accurate and reliable pill I've used. While some rifles didn't like it as much as others none refused to group at an acceptable level with it. I never really experienced any feeding or functioning issues with that design although it did have a rep of being a little finicky in semi auto's.

-

20-11-2022, 08:53 AM #40Banned

- Join Date

- Mar 2015

- Location

- North Canterbury

- Posts

- 5,462

-

20-11-2022, 04:27 PM #41Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,104

I sort of put it down to the wall thickness of the projectile nose section ahead of the 'driving band' being thinner and more able to expand. It's not much thinner, but with these little pills it doesn't take much to make quite a big difference in performance (eg. the difference in effectiveness between a 2.5mm hollowpoint and the same in 3mm as noted with the dies above). Win called it a 'truncated cone' - the wacutter for me was always a cylindrical bullet with a recessed face. But yes, that style bullet was the most effective I've used by a country mile in the .22's regardless of any other factor. I'm a bit gutted you can't get it easily now, and if you could get a die to form them reliably out of round nose target pills I'd be keen for one!

-

20-11-2022, 08:37 PM #42

I have been toying with the idea of trying a punch to do this. It may be too much work on the projectile considering it's only held by the case crimp, but would be interesting regardless. May even be able to get really trick and incorporate a hollow point stem into the same punch.

One issue I am getting trying to get a very deep hollowpoint is blowing the nose out too much and losing the nose/drive band difference.

-

20-11-2022, 09:31 PM #43Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,104

I don't think it needs to be a very deep hollow point, just deep enough to start the upset... I wouldn't as an example be looking to drive the hollow point into the driving band section, just deep enough to let it do it's job.

I suspect the profile with the step between the truncated cone and the driving band section is what will be the difficult bit, it might require something to be firmly grabbing the case and pill and go from there.

-

21-11-2022, 08:48 AM #44

Reforming the profile and adding a hollow point will improve accuracey in some firearms but be detrimental in others.

Borrowed from another site

A Sporting .22 LR chamber is .8751 in length from the bottom of the rim to the top of the throat compared to .6876 for the Match chamber. The length of the Sporting chamber from the top of the rim to the start of throat is .818 compared to .643.

The Sporting chamber at the base of the cartridge is .2307 wide compared to .2267 for the Match chamber. At the throat the dimension of the Sporting chamber is .227 versus .2248 for the Match chamber.

Rim thickness in both is .043 min and .051 maximum.

What this means is that the sporting chamber is substantially larger than a match chamber designed to shoot high quality ammo. High quality ammo, despite being produced to tighter specs may not shoot well in larger "Sporting" chambers due to improper headspacing, chamber slop, etc.

What it also means is that low quality ammo may not even fit in match chambers because it is designed to be oversized at the factory to fit sporting chambers. Find the right ammo for your sporter and you may be able shoot good groups with a sporter.

Buy a rifle with a "Match" chamber, use high quality match ammo and you will be able to shoot tiny groups. Match ammo has very consistent rim thicknesses, powder charges, bullet seating, bullet weight, bullet length, etc. A match chamber gives you the potential to shoot championship groups.

There are "accuracy nuts" who have found very the most dimensionally perfect ammo for their Sporting chambers allowing them to shoot small groups. The variable comes in when there are inconsistencies in the ammo.

Dimensions from SAAMI and published in the Small Caliber News, Winter Edition 2003. Vol. 6 No. 4.

As a chamber reamer wears in barrel production the chamber tightens . profiling a 22lr bullet may shoot well in one rifle and in another of the same type not. The Norinco JW15 and the Ruger 10/22 are examples that I have owned that have demonstrated this inconsistency

-

21-11-2022, 09:06 AM #45Member

- Join Date

- Dec 2021

- Location

- Tauranga

- Posts

- 5,104

That's true, but in practical terms for the average rifle driver a 0.0022" variation in chamber size is likely going to be less variation than the ammo you can consistently source... Being able to find something that works and retune the ammo you can get in some form stands to be potentially more reliably accurate than relying on chance!

The ultimate out of this would be able to buy a 10,000 bucket bulk pack of soft solid nose and slamming them through a process which gives you reliable hunting ammo to fit a standard sloppy chamber. I suspect that's where the Powerpoint was so reliable, the driving band section was very consistent.

Similar Threads

-

Hollow Point 22lr to reduce Ricochets

By SixtyTen in forum Varminting and Small Game HuntingReplies: 33Last Post: 04-07-2024, 07:28 PM -

22lr subsonic Hollow point

By rambo-6mmrem in forum Firearms, Optics and AccessoriesReplies: 51Last Post: 08-09-2020, 11:50 PM -

Winchester 22LR Subsonic Hollow Point Chronograph results

By smidey in forum ShootingReplies: 44Last Post: 26-05-2015, 11:58 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

179Likes

179Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks