Hi all, yep have set up one of the 4140 steel shafts in my lathe ready to drill a .444" hole in for 28". Now running two oil pumps for more volume and pressure and mixed in 5ltrs of Coolcut cutting oil to my hydraulic oil, should help keep the drill sharp and cool. And speaking of sharp I worked out a way to sharpen my gun drills on my lathe with a small diamond grind wheel, used to cost me $50 each to get them sharpened, can't beat do it your self. IF it comes out any good still thinking what rifling twist should I do, 1-18" or 1-20" with a 27" barrel.. Pic`s of the setup.

,

, All ready to go.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 26

Thread: Gess what I`m doing.

Hybrid View

-

23-07-2018, 08:43 PM #1

Gess what I`m doing.

-

23-07-2018, 08:53 PM #2

-

25-07-2018, 06:59 PM #3Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,220

brew ya old bugger nice to see ya back in print again -thought ya mighta buggered off into the wideblue yonder. still the craftsman i sees!

-

25-07-2018, 07:12 PM #4Member

- Join Date

- May 2015

- Location

- Southland

- Posts

- 1,063

Gess what I`m doing.

Making a fancy tool to fix the "U" key on your keyboard!?

Seriously, waiting in anticipation!

-

25-07-2018, 08:41 PM #5

It`s my bloody brew that does that, thakes controle of ma fingres . The grenlins are creeping in, set my drilling rig going, oil pressure at 400psi and it`s pissing out off the barrel stock end, I hadn't pushed the stock hard onto the drill guide seal ring.

Buugggger!!. So the car looks nice and shiny, the garage walls and ceiling are nice and clean," O darling, I see you have cleaned the car AND the garage, and you have had a bath to!!!, wonders will never sťance.

Buugggger!!. So the car looks nice and shiny, the garage walls and ceiling are nice and clean," O darling, I see you have cleaned the car AND the garage, and you have had a bath to!!!, wonders will never sťance.  Mums the word. So I`m starting all over again, some days it pays to stay in bed.

Mums the word. So I`m starting all over again, some days it pays to stay in bed.

-

27-07-2018, 06:55 PM #6

After a few brews all is back on line and going good, resharpened the drill, all set up again and back into it. After a day on it I have about 14" to go in to give me a 28" deep hole. I can't lay in bed all day ,have to get the job done and yes the stock is hard up on the o ring seal, no, not a drip at 400 psi,

, Anyone want a nice bowl of chips.

, Anyone want a nice bowl of chips.

-

28-07-2018, 08:40 PM #7

I know you are all having bets as to will he flood the garage with oil, will the gun drill break in the bore and stuff things up. O all ye of no faith, my moto is ("There`s no such thing as Can't do it")!!. So to all you non believers I`m putting my mouth where my money is, Here`s a bloody long hole in a shaft of hard steel, 29" and entry to exit hole is only off centre by .004" , am I good or what!!

. Just need to ream it ,then cut the rifling, no problem, I think.

. Just need to ream it ,then cut the rifling, no problem, I think.

, Now is that not a lovey hole!!

, Now is that not a lovey hole!!

-

10-08-2018, 12:05 AM #8Banned

- Join Date

- Mar 2015

- Location

- North Canterbury

- Posts

- 5,462

-

28-07-2018, 09:01 PM #9

Very well done! IF your intrested, special steels and metals can supply pilot drilled barrel bar or should I say used to, comes from sweden.

-

28-07-2018, 11:11 PM #10

-

01-08-2018, 08:54 PM #11

What, a gain twist, I thought that was only with a old Navy .44 pistols. I`d need a sine bar like a crank handle. Now the bore is not bad but just needed reaming to clean up the drill scratch marks and smooth it out and enlarge it for the rifling cutter head to fit. I make up my own homebrewed reamer, it`s a 8"inch long flat bit of steel with a length of hack saw blade solded on one side and ground straight on the sides. Bottom has three pins to hold a packing bit of hard wood, this rubs on the bottom of the hole while the H/ blade is pressed against the top of the hole. It`s the square edge that scrapes the bore as it is wound through and with lots of cutting oil the metal coming off is like grey mud. To make it cut a bit more a thin strip of paper is placed between the packer and pins.

, Coming out with grey mud, sharp edges of blade scrapes the bore smooth.

, Coming out with grey mud, sharp edges of blade scrapes the bore smooth.

, Reamer, paper packer, wood base.

, Reamer, paper packer, wood base.

-

02-08-2018, 09:31 PM #12

-

01-02-2019, 09:46 PM #13

-

01-08-2018, 09:11 PM #14

cleaver wee hua arent you just...... real #8 WIRE STUFF keep it coming bud.

-

02-08-2018, 11:01 AM #15

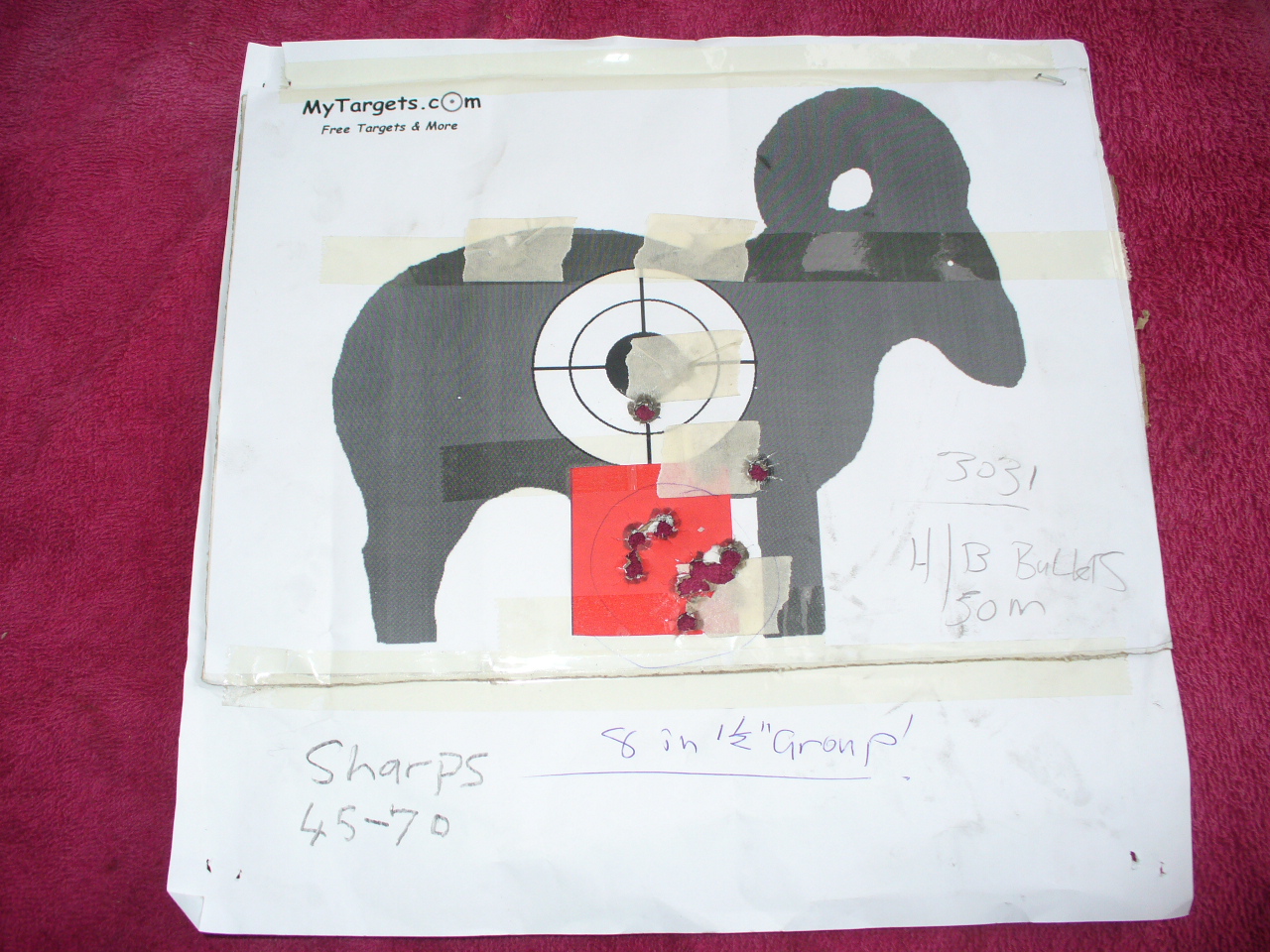

Well they say you can't beat results, I did the same thing when making my Sharps barrel and the drill bores a hole to .442"/ .444" , for the rifling head to slide nicely it needs to be .444" so not much is removed. So yes I`m the clever chap as my Sharps is telling me.

, Practise for a goat shoot.

, Practise for a goat shoot.

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

45Likes

45Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks