Hi Guys, Have been waiting for a redo of my hip op, Just got called up for it but it is a temparey one, only 3/6 months and then the finale one, so no more lathe work for a bit:, Homebrew.357.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 31 to 45 of 59

-

28-07-2014, 09:55 AM #31

-

-

28-07-2014, 02:28 PM #32While I might not be as good as I once was, Im as good once as I ever was!

Rule 4: Identify your target beyond all doubt

-

30-07-2014, 01:27 PM #33

Well thank you Scouser, I am honoured by your words, but not for long, now I can strut my stuff , but lucky there`s no toolmaker / engineer looking over my shoulder , the way I do things would have him pulling out tuffs of hair!, screaming ,

"YOU CARN`T DO THAT'!!!.

"YOU CARN`T DO THAT'!!!.

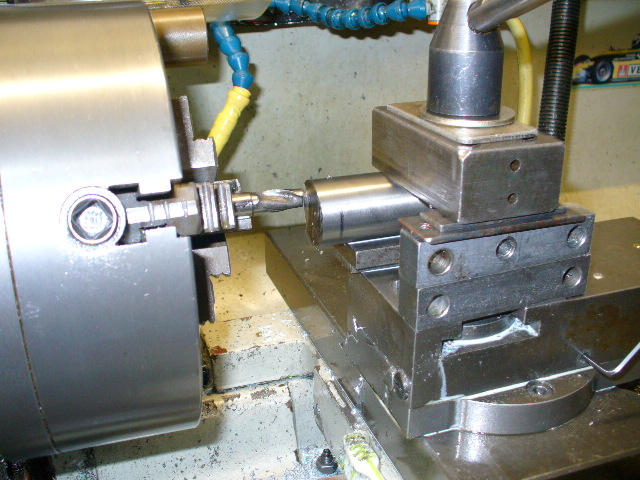

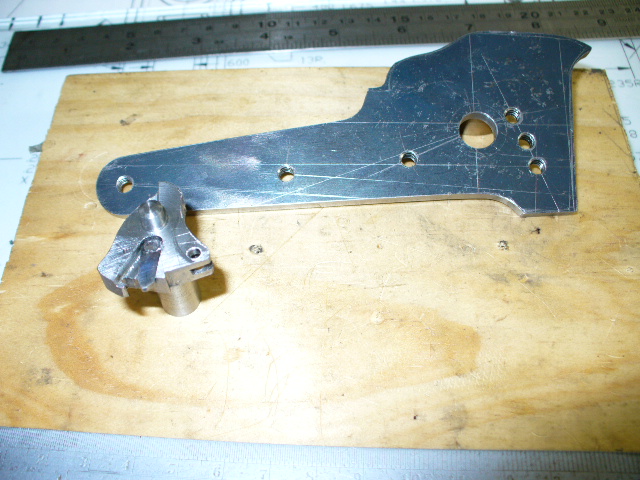

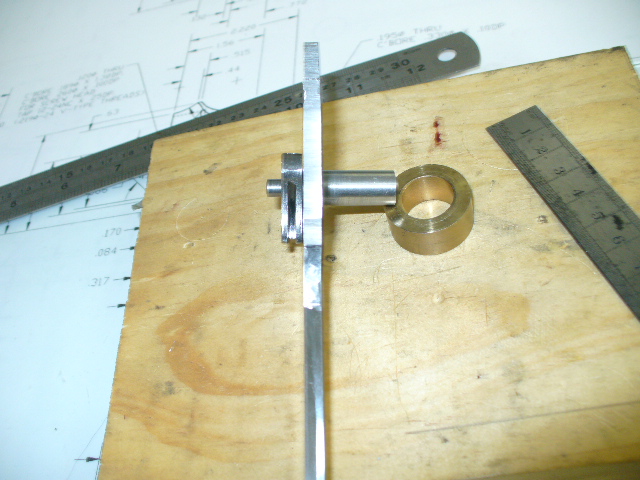

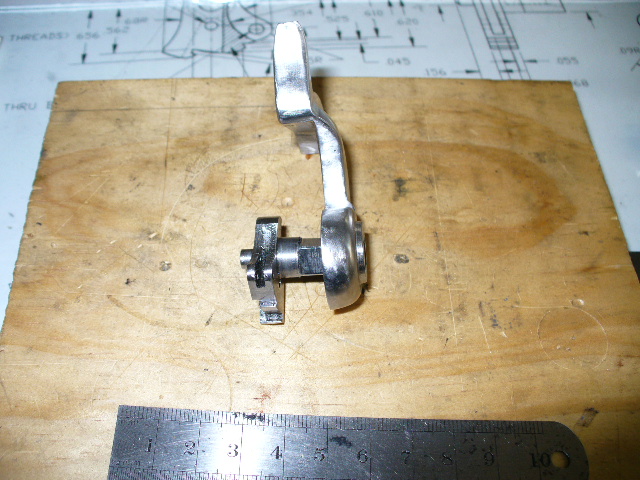

Now here`s a good example, making the tumbler with a round bit of 4140 steel on the lathe , set stock up in the tool post to cut a radi with milling cutter set off centre to fly cut . then in fore jaw chuck set off centre to machine body of tumbler. Now a shaping cutter made from a t/c tipped saw blade, (Very handy old t/c saw blades), is used to cut the sear and half cock notch and then cut it off the stock and set up in tool post again to mill out the slot for the fly on the side. The plans had it in the middle , but I could not do that, so it`s on the side, works on my Hawken. Cheers, Homebrew.357.

-

30-07-2014, 01:32 PM #34

more pic`s

more pic`s

Last edited by homebrew.357; 30-07-2014 at 01:40 PM.

-

30-07-2014, 02:05 PM #35

Thats what im getting at Homebrew, by putting the milling cutter in the chuck and 'bolting/fabricating' the part you want to 'mill' on the lathes saddle you circumvent the problem.....SWEET AS.......

As long as you keep the saddle tight on the threads so you get no 'backlash' and hence no 'chatter marks'.......but im teaching my granny to suck eggs....eh!....well done mate, an awful lot of patience required to do what you do (so well) While I might not be as good as I once was, Im as good once as I ever was!

While I might not be as good as I once was, Im as good once as I ever was!

Rule 4: Identify your target beyond all doubt

-

13-08-2014, 09:34 PM #36

Hi, Having a go at carving out the hammer from a chunk of 1045, yep the hard way, milling on my lathe, good things take time. Any way I have made the little side plate for the tumbler and had a go at jeweling it so it looks nice on the inside.

Cheers, Homebrew.357.

Cheers, Homebrew.357.

-

13-08-2014, 09:40 PM #37

Looks great! You're going very well.

10MRT shooters do it 60 times, in two directions and at two speeds.

10MRT shooters do it 60 times, in two directions and at two speeds.

-

26-08-2014, 09:08 PM #38

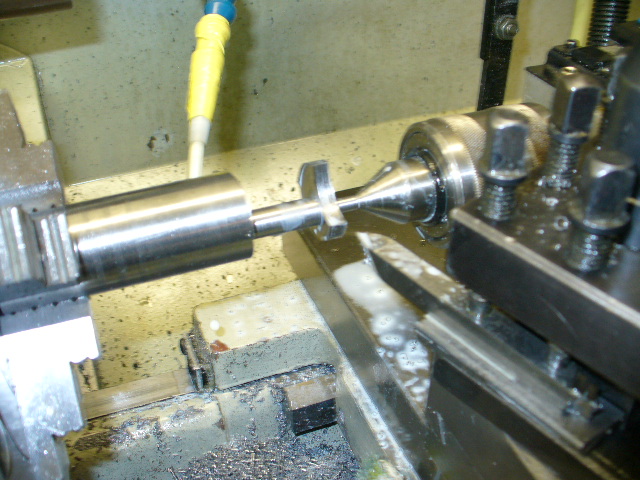

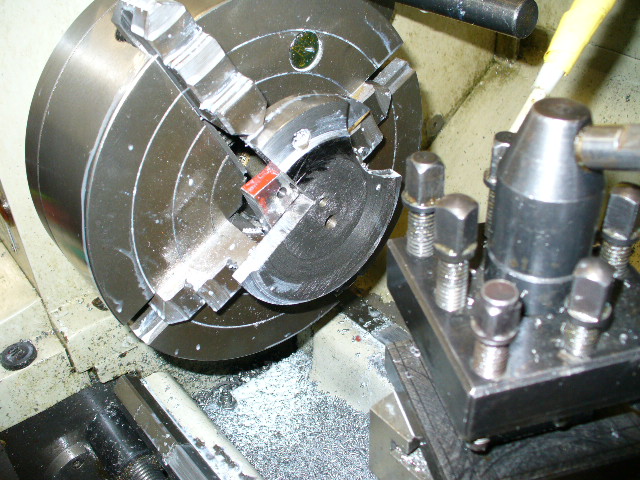

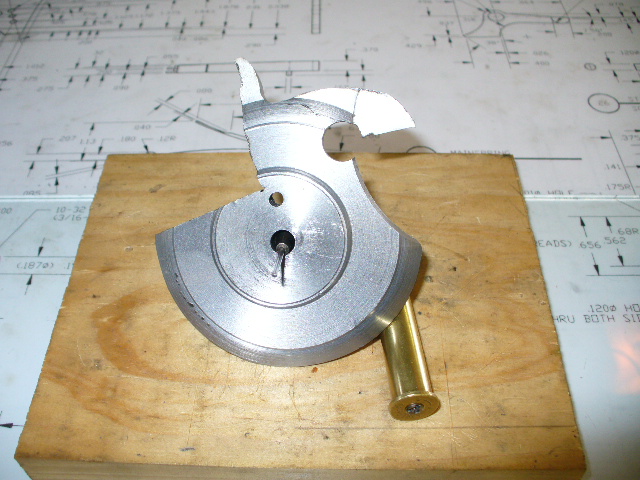

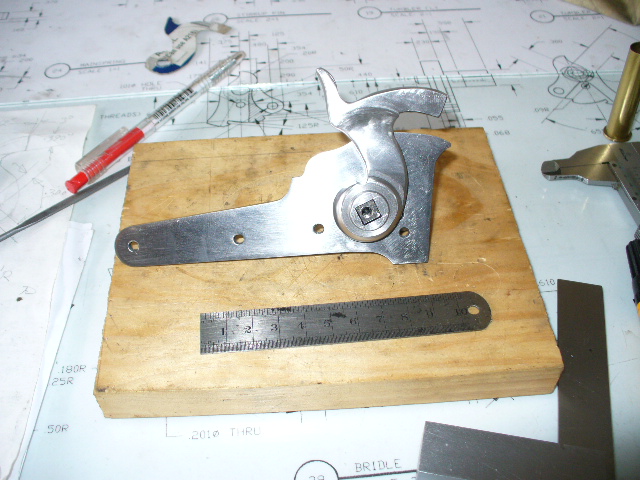

Hi Guys, Still hobbling around on my crutches and yea, back on to my lathe, carn`t stand sitting around. Like I said, I`m making the Sharps hammer from a round lump of steel, here is how it was done. Set up a and drill the holes, some holes are just for profile and this gives you a datum point to work from to do most of the machining . Made up a cutter to cut the top profile on the outside of the hammer, now this could not be turned full circle , so it was cut by the ( Rocking the baby ) way, chuck back and forth ectra, until your arm falls off.

A lot more work to do yet, have to cut the square hole for the tumbler shaft and square the shaft to fit, its good to have a hobby, , OK the photo shoot, Cheers, Homebrew.357.

, OK the photo shoot, Cheers, Homebrew.357.

-

29-08-2014, 09:00 PM #39

The hammer is coming along nicely , the hole in the hammer for the tumbler shaft had to be square, so set up the hammer in fore jaw chuck centred on the hole then using the lathe saddle as a shaper with a small square cutter I slowly cut across using cross slide then turned chuck to register for the fore sides , now how is that for thinking outside the square

, Then some filing and fine sanding to get a good finish, I know my stuff

, Then some filing and fine sanding to get a good finish, I know my stuff  , so here is the hammer, Cheers, Homebrew.357.

, so here is the hammer, Cheers, Homebrew.357.

-

29-08-2014, 09:24 PM #40

Far out that is impressive work!!

-

29-08-2014, 09:53 PM #41

-

30-08-2014, 12:35 AM #42

If you want to make another as a project PM me and we'll talk a deal

-

03-09-2014, 09:02 PM #43

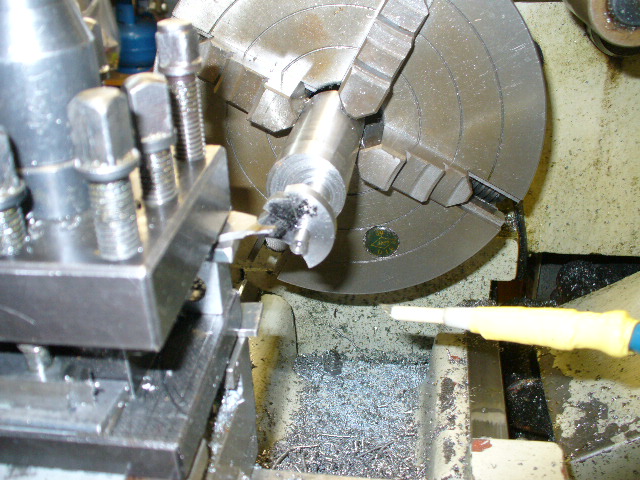

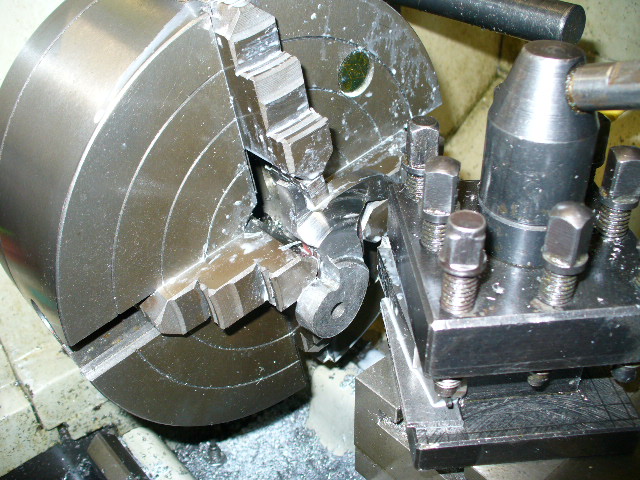

Hi Spanners, Lost the plot there somewhere . So moving right along there, set the tumbler up in the fore jaw chuck to cut the square for the hammer. On the top slide a t/c cutter is packed up in the tool post and cuts the square like a shaper, back and forth on the hand wheel, about 3,000 times per flat and your wrist falls off.

.

.

Then some finale fitting to finish it off, it fits, , Ok, the pic`s, Cheers,

, Ok, the pic`s, Cheers,  , Homebrew.357.

, Homebrew.357.

-

03-09-2014, 09:17 PM #44Member

- Join Date

- Nov 2012

- Location

- BOP

- Posts

- 21,385

Your a patient man, and stretch the brain to acheive what you have done, impressed

Boom, cough,cough,cough

Boom, cough,cough,cough

-

03-09-2014, 10:16 PM #45Member

- Join Date

- Jun 2013

- Location

- Middle Earth

- Posts

- 4,560

Are you going to heat treat the trigger and hammer cocking parts?

Similar Threads

-

Legend in the making

By Pengy in forum FishingReplies: 2Last Post: 12-03-2014, 08:46 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

100Likes

100Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

. Yes I`m building it good and strong, that is until I give it a good stiff proof load !

. Yes I`m building it good and strong, that is until I give it a good stiff proof load ! , some pic`s before I blow it up, Homebrew.357.

, some pic`s before I blow it up, Homebrew.357.

Bookmarks