Howdy,

I'm just about to start loading up some BP shotshells but am getting stuck trying to make some decent fibre wads, closest I've had to success so far is a 22mm hole saw into MDF (I think) giving me 18mm wads but they are very flaky and fell apart while measuring.

So, What do you use for wad material? and how are you cutting it?

I've seen mentions of pinex, cork and wool being used, but cutting it would still be my sticking point.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 52

Thread: DIY Fibre wads?

-

24-10-2023, 03:18 PM #1Member

- Join Date

- Dec 2022

- Location

- Northland

- Posts

- 116

DIY Fibre wads?

-

-

24-10-2023, 03:28 PM #2

I used to use ceiling Pinex. Can you still get Pinex though? Mate had a special 12g cutter that you put in a drill press for making wads.

IIRC I had one thin stiff overpowder wad (cut with correct sized wad punch) followed by 2 Pinex wads, one dry and one lubed. I lubed the wads by dunking them in a hot sausepan of cooking oil (crisco?) of some sort.

Same thin stiff wad over the shot. I gave up roll crimping or folding and just ran a track of pva glue around the outside of the over shot wad. Although the pva doesn't stick well to plastic hulls I never had a wad come loose in the second barrel (and all the shot rolling out of the barrel) when firing the first barrel of a double barrel shotgun.Last edited by zimmer; 24-10-2023 at 03:35 PM.

-

24-10-2023, 03:34 PM #3Member

- Join Date

- Dec 2022

- Location

- Northland

- Posts

- 116

Seems like you can still buy pinex tiles (https://revivebuildingrecyclers.co.n...ts/pined-tiles) , I've got some board similar but its quite a pain to cut and comes out at 17mm with the same 22mm hole saw, so undersized for 12 gauge which should be a smidge over 18mm just converting the numbers from inches,

hopefully someone has a decent idea for cutting them.

I think I've got the overshot card sorted doing it like you described, just have to get some decent punches as the ones I brought wouldn't cut the cereal box I was using. was just stuck on the wads, maybe someone has a tool they wouldn't mind duplicating for me.Last edited by NAKED_GOOSE; 24-10-2023 at 03:41 PM.

-

24-10-2023, 03:39 PM #4

Yep, those tiles are thinner than the older original Pinex I used. Would need to put in maybe an extra wad. As far as using a 22mm hole saw it might work if the teeth are removed by grinding down leaving just a sharp ege. Pinex is too thick to wack with a wad punch unfortunately.

Wads need to be tight in the barrel so there's no blow past and destruction of the pattern, also the tight wads help to sweap the barrel of BP muck.

-

24-10-2023, 03:48 PM #5

The cutter I used belonging to a mate was specially made to cut 12g wads. Back then those sorts of things were available. It had a sprung centre plunger that popped the wad out once cut. Even if successfully cutting them with a hole saw it would be a pain getting each wad out of the saw. And of course, hole saws never seem to exactly cut the hole to the size of the saw bloody things.

-

24-10-2023, 03:50 PM #6Member

- Join Date

- Dec 2022

- Location

- Northland

- Posts

- 116

The stuff I've got laying around is 25mm thick which is what im using for experimenting have around 4 square meters of it, can always cut and/or stack wads where needed I guess,

Forgive my ignorance but why remove the teeth of the hole saw?

I have certainly had issues getting the wads out of the hole saw, I'll have a look around and see if theres a tool somewhere overseas that might work well, would be easier If I could just buy the pre made wads, much like the 12g brass though they seem to be unavailable

-

24-10-2023, 03:54 PM #7

I think 25 mm is the old thick Pinex, not the Michelangelo version of ceiling tiles.

To make the holesaw into a knife rather than a messy ripping saw. Effectively a rotary wadcutter like my mate's.

-

24-10-2023, 04:00 PM #8Member

- Join Date

- Dec 2022

- Location

- Northland

- Posts

- 116

That makes sense, Guess ill try that for now and see if I can make any useful wads that way.

-

24-10-2023, 04:04 PM #9

@NAKED_GOOSE Just found the remainder of my old wads. I'll photo a phot and dimensions.

-

24-10-2023, 04:17 PM #10Member

- Join Date

- Dec 2022

- Location

- Northland

- Posts

- 116

Many thanks,

From what I've found I should be aiming for 0.710" for winchester hulls, but .750" for cheddite and then .760 for magtec brass (which I dont yet have)

-

24-10-2023, 04:20 PM #11

Card, greased pinex then shot is my version the grease sort of glues the wad together and makes it much easier to load. Pin in the wad and a quick dip in beeswax /lard 1:1 then allow to harden .

-

24-10-2023, 04:22 PM #12

I think I used Eley plastic hulls.

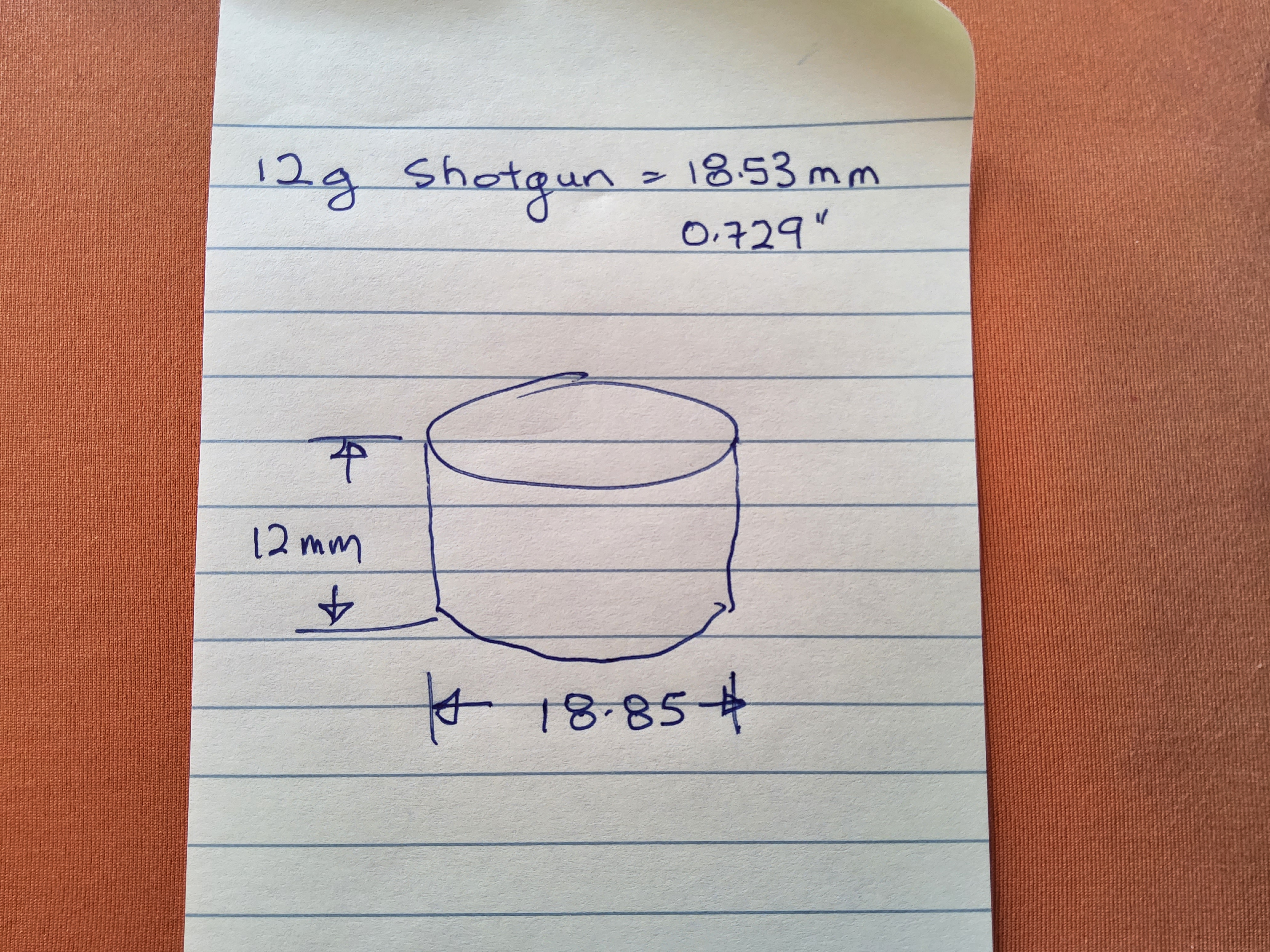

Here's a couple of photos.

Cannot understand how my Pinex is 12mm as it well and truly predates metrics.

I also loaded 16g but have no memory of what wads I used or how I cut them.Last edited by zimmer; 24-10-2023 at 04:27 PM.

-

24-10-2023, 04:22 PM #13Member

- Join Date

- Dec 2022

- Location

- Northland

- Posts

- 116

Ive got some lanolin and beeswax sitting around waiting to be made into lube for 44/40 but figured I'd play with the shotgun first sounds like it'll be useful here too,

How are you cutting wads from the pinex?

-

24-10-2023, 04:25 PM #14Member

- Join Date

- Mar 2012

- Location

- Christchurch

- Posts

- 1,334

I tried a simple home made hit it with a club hammer type punch for 20ga wads using Pinex wallboard which is about 10mm thick. It seemed to work a bit but the edge of the punch rolled over after a few wads, so I have not carried on with the project. I'll make another punch and try it in the drill press.

-

24-10-2023, 04:26 PM #15Member

- Join Date

- Dec 2022

- Location

- Northland

- Posts

- 116

Looks like I'll need to track down a tool, those wads look fantastic compared to what I managed to get with the hole saw, even with the hole saw I'd need a strange size like 23mm to get 18.5-19mm wads

Similar Threads

-

"Desperately seeking", no not Susan, a 12 bore load with fibre,not plastic wads.

By Kiwi Sapper in forum ShotgunningReplies: 47Last Post: 27-11-2022, 11:38 AM -

Wanting to buy 12g wads

By Kiwilad2021 in forum ShotgunningReplies: 2Last Post: 07-07-2021, 10:42 PM -

Wtb 12 gauge wads

By Kiwilad2021 in forum Reloading and BallisticsReplies: 6Last Post: 07-07-2021, 10:40 PM -

Gualandi Shotgun Wads

By Xpat in forum ShotgunningReplies: 2Last Post: 19-07-2019, 09:52 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

34Likes

34Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks