You will find that .314" cast bullets shoot better than the smaller diameters, Not many .303 barrels are even close to .312" even new barrels are more likely to be 313"

The throats on them a worn from the cordite trying seat the bullet to touch the rifling is a waste of time seat the base of the bullet level with the base of the neck to give the bullet

good support, My mould casts bullets at .315" bullet I only have a .314" size die, If you want to get a mould order one that is .002" over groove diameter it will have to be a custom

order the usual mold makers don't do special orders, Or powder coat thebullets that adds about .002" .

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 16 to 26 of 26

Thread: Casting for an SMLE

-

17-12-2021, 12:16 AM #16Member

- Join Date

- Dec 2013

- Location

- Tokoroa

- Posts

- 1,221

-

-

17-12-2021, 07:38 PM #17Member

- Join Date

- Dec 2019

- Location

- Okawa Hawkes Bay

- Posts

- 3,397

Greetings @Sixty Ten,

You might want a collector to look at the hollow point cartridge. The Brits did make a hollow point 215 grain in the Calcuta Arsenal or it might just be a Mark VI that someone has hollow pointed. The pointy one is a Mark VII. Others will know more.

GPM.

-

18-12-2021, 08:57 PM #18

I have been assembling components to load for this rifle over the last few days.

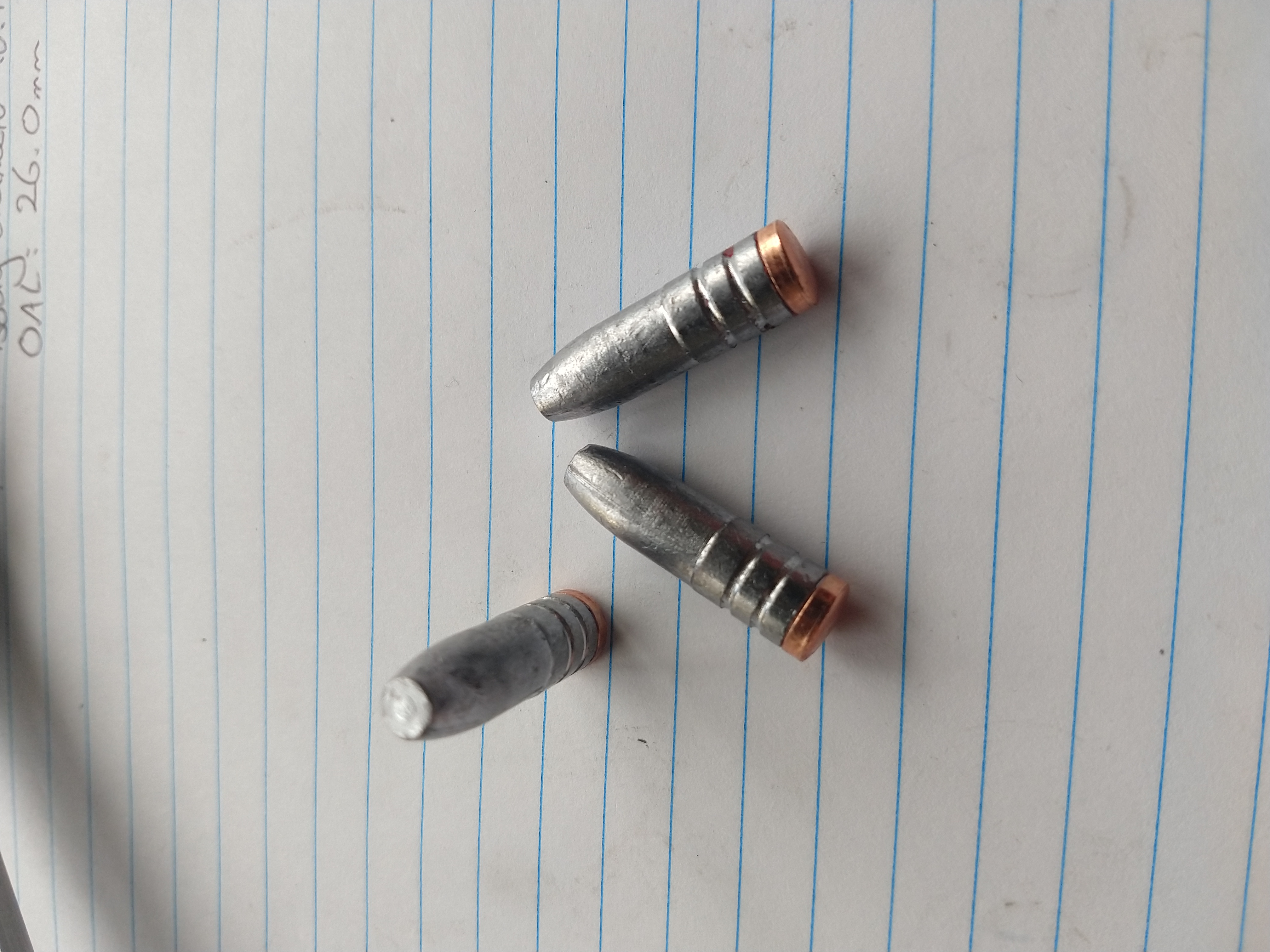

I ordered 50 210gr cast projectiles for a good price from Shooternz, and they showed up very quickly and look good.

I also dropped into gun city and bought some of the Greek brass they are selling. Some of it is pretty tragic, but it mostly looks good. It was the only 303 brass I could find in Auckland, so we will see how it goes. At $30 for 50, I'm not too fussed if it ends up in the bin. I de-primed all of them and found 4 that had heavily corroded primers. All the others looked fine, so given the current climate, I will use the original primers for initial testing.

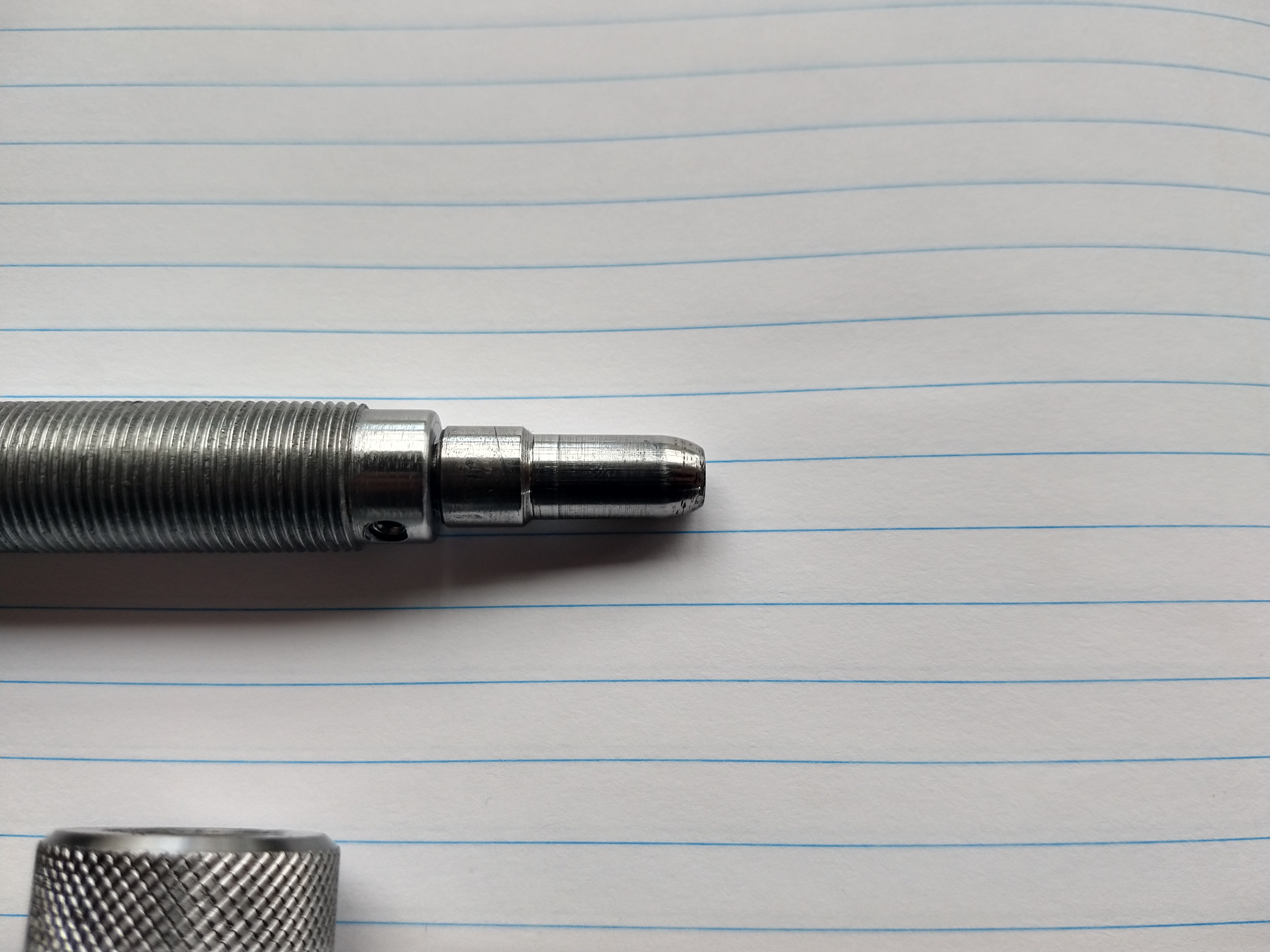

I also made a 303 case holder for my Wilson case trimmer. These are pretty easy to make so long as you get the compound slide on the lathe set just right for cutting the internal taper. I have made 5 or 6 now for various random cartridges I load for. Much better than spending $30 per holder.

I am currently waiting on some sulphur to arrive so I can attempt a sulphur/graphite chamber cast. I am also going to order a Lee collet neck sizer + seater.

It's amazing how much crap you need for loading a new cartridge. I have several drawers full of reloading gear already and it just keeps on growing.

Any suggestions on powder for this load? I have AP100, 2205, 2206H and a little 2209 on hand and likely won't be getting anything else until the next powder shipment arrives in NZ. 2209 seems the best candidate to me.

-

18-12-2021, 10:27 PM #19

my man,thankyou...you have solved a mystery for me as to what some bits Ive inherited are for and how they are used.....that photo is just what I needed to see LOL.

so I take it you trim to length...and can de burr inside n out just by changing cutter head for each operation?? or does cutter and handle slip through body and slip next one in??

might have to talk nicely to @RUMPY and he can fabricate up the missing bits LOL

-

20-12-2021, 04:59 PM #20

I think you can get case chamfering tools to fit in this, but I havent bothered. The length trimmer is pretty well fixed to the handle, but does slip out the back easily, so you might be able to sort out a couple more handles to put chamfering tools on.

I made myself a little handle for inside and outside deburring so its both tools in one "tool" basically just copied this: https://www.youtube.com/watch?v=A2t3nFYrJec

I have found it works really well once you get the feel for how much pressure to apply for each cutter. Certainly cuts down the time swapping tools and is also easier on the wrists than your standard handles.

My plan eventually is to try and re-grind a carbide cutter along the lines of the Giraud case trimmer to replace the cutter head on the Wilson so that it will length trim and inside and outside chamfer in one hit. Only downside is you need to set it up for each caliber every time you change. Wouldnt be worth it for general reloading, but I just processed around 2000 .223 cases, and have another 1000 to go, and any little gain pays off big when working through that many.

-

20-12-2021, 06:52 PM #21

I usually just use LEE trim thingy that slips up guts of case to ensure it trims to correct length,then while still attached to cordless drill,do champher thing too.... quick n easy.

-

11-01-2022, 08:30 PM #22

I ended up making my own copy of a Lyman M die as well as a 0.318 sizing stem. With my projectiles being around 0.3190 after powdercoating, there was no way they would seat in a standard sized neck. I am using a Lee collet die to size the neck and am finding it very useful for tidying up dented and crinkled necks. I then run them through my neck sizer die to open the neck out. The mandrel has a small step in it so the first 2mm of the neck is sized to be a slip fit for the projectile so you can place the projectile by hand and it starts nice and centered in the case

I still need to make a lock ring for the sizing stem adjuster and I may blue the whole thing to reduce rust. It's made to have interchangeable sizing stems, so one die body will work for most cartridges with just swapping the sizing stem.

-

11-01-2022, 08:54 PM #23

@SixtyTen the holow point looks like the original Dum Dum bullet (made in Dum Dum) must be a collector piece.

-

12-01-2022, 08:07 PM #24

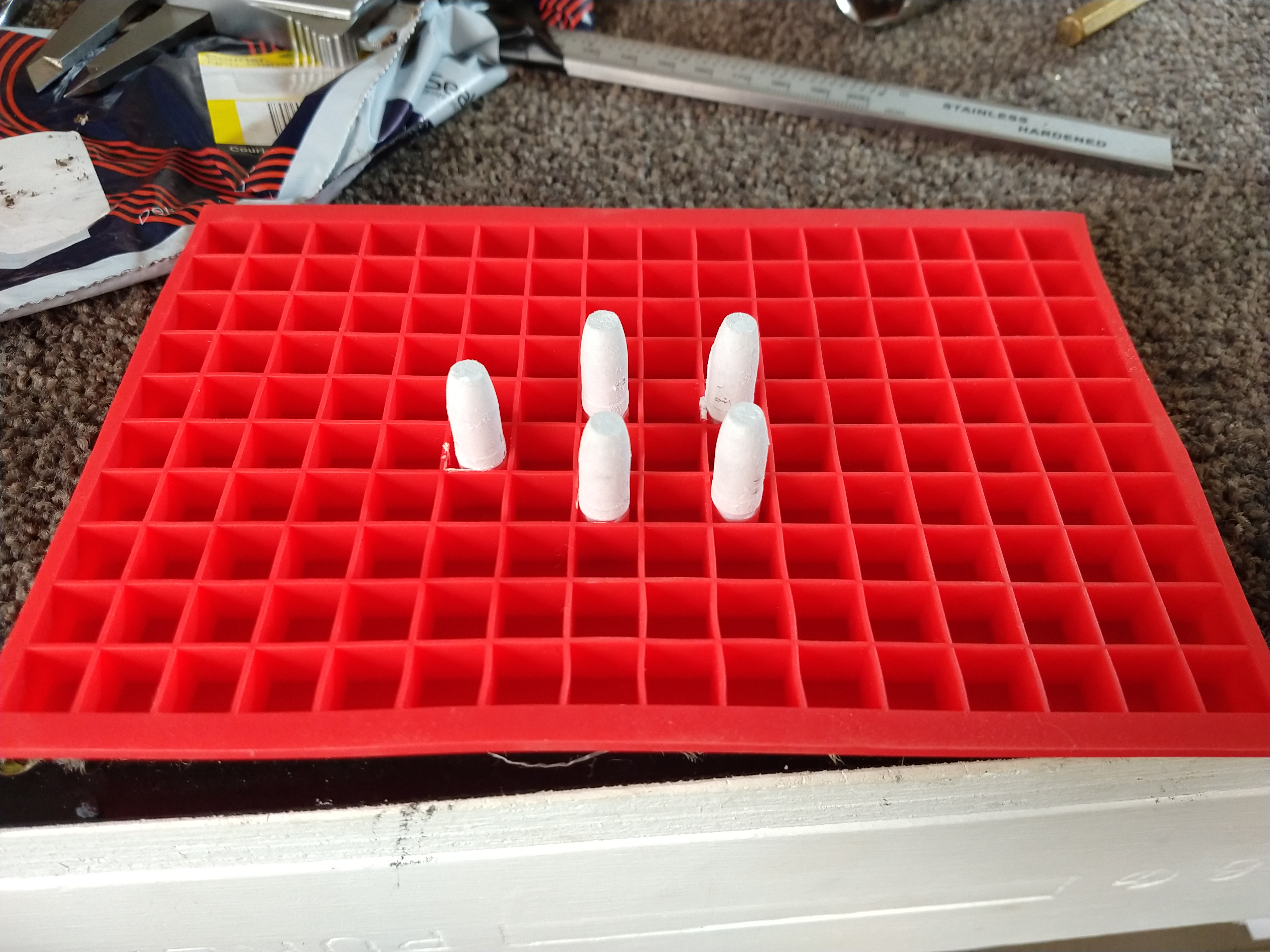

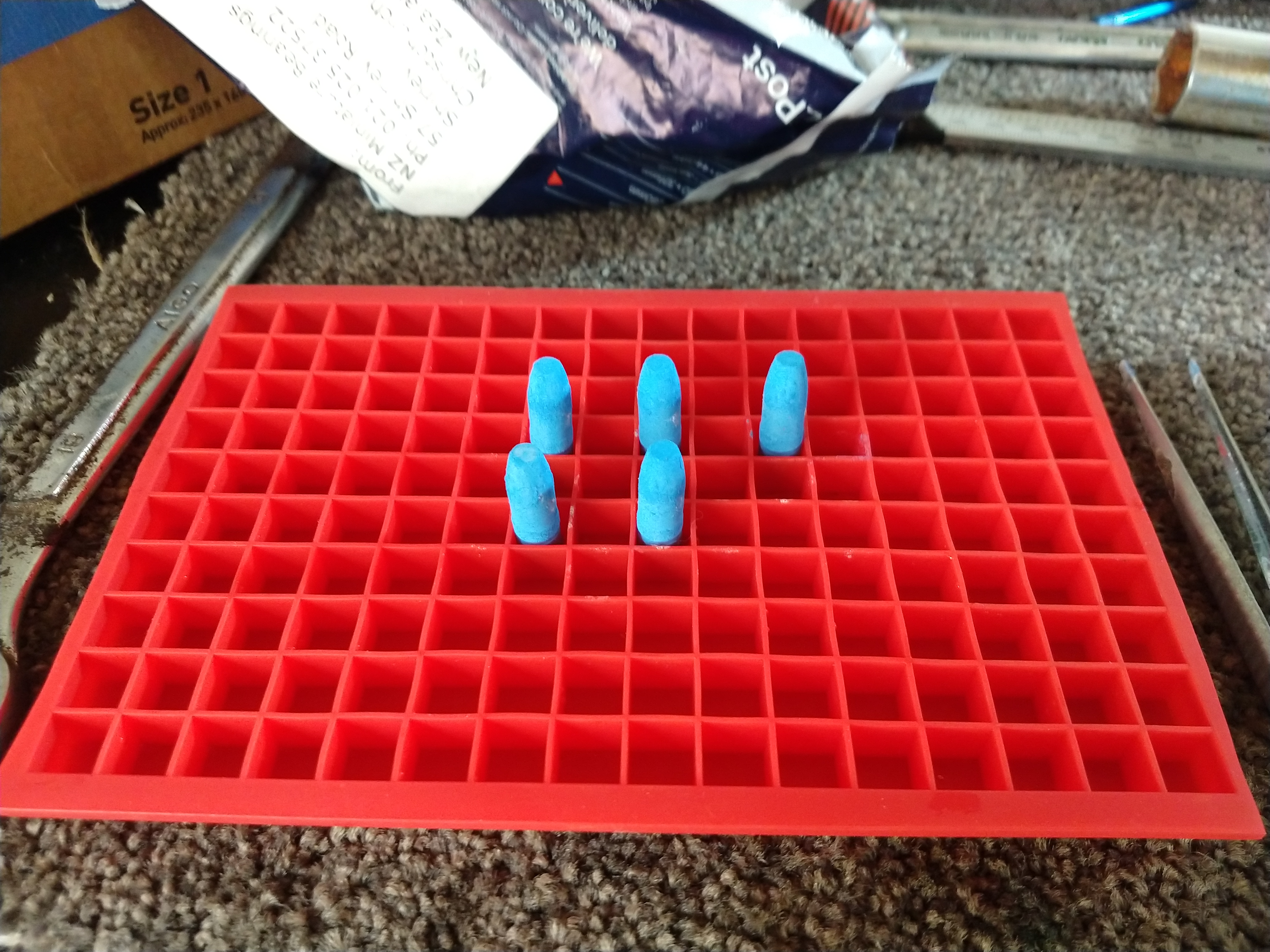

I have been playing around with a few different powdercoats. I only had Eastwood's Gloss Black until recently and have been getting pretty average results. I have also been struggling to keep the tall and skinny bullets standing up while moving the into the oven.

As such, I bought some Eastwood's Super Gloss Clear and Ford Light Blue to try as I have it on good authority that both these powders work well. I also purchased a silicon mini icecube tray off eBay which it just so happens has squares that are a little larger than 0.30.

I was experimenting with dissolving the black powder in acetone and then dunking the projectile, letting the solvent flash off, and then dunking again. I got some decent coverage like this, however I also got some solvent pop on some that obviously had trapped solvent when baking. It is also a smelly and time consuming method.

The clear and blue were so much easier to get an even coating on. I think I will use the clear going forward as I like the look of as cast projectiles and you also can't see any of the paint defects.

I had loaded up a few rounds and tested them on the weekend.

The load was 210gr projectiles at 0.3190, 27.0gr ADR2205, and the original Greek primers. Simulator estimates 2000fps for this load.

I shot 4 rounds sitting at 100yds (grass was way too long for prone) and got a group of around 2.5". I have no idea of the velocity, but I had my sights set to 300yds at a guess and was shooting only a few inches high. This was not a very scientific test, but the projectiles and rifle show promise, so I will load a bunch more of this recipe and do some proper testing when I get a chance, I might bump the charge up a little, but should start to get close to 50kpsi at around 29-30gr, so don't want to push it too far.

-

26-03-2022, 08:52 AM #25

-

26-03-2022, 11:09 AM #26

You really don't want to or need to push cast bullets over 2000fps even with gas checks leading becomes a problem due to friction and heat.

Similar Threads

-

SMLE 303

By Jusepy in forum Firearms, Optics and AccessoriesReplies: 137Last Post: 26-08-2021, 11:10 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

44Likes

44Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks