If you think you've seen bad ones, you should try being the poor sod who has to take them out of the box, remove them from the plastic bag containing the rifle and about half a KG of stinky cosmoline, strip it all down clean, then mount the POS scope that comes with them, before realising it's not fit for sale. When I was in the trade we would send an alarming proportion of JW-15's back to the importers before they even went on the shelf, off the top of my head, problems were included but not limited to:

Chamber not concentric to bore

Safety almost impossible to operate

Open sights canted so badly you couldn't line them up

Muzzle thread not concentric to the bore so the customer shatters the suppressor, and then the replacement suppressor with the first bullet through it

Sear being out of whack to the extent the thing wouldn't go off no matter how hard you pulled the trigger

Bolt being so rough that cycling the action was hard and inserting/removing the bolt pretty much required bracing the butt on the ground and 'mortaring' the thing

Off-centre bore

Seeming normal but then the customer finds you couldn't close the bolt on a live round

Seems to be a quality control issue rather than a quality issue per se; it's a good design and some of them are as good as the Brno/CZ they're copied off, most are rough but serviceable and the bolt wears smooth over time, and the rest are un-useable. I've also seen a few of the wooden stocked ones break through the pistol grip area, it's some kind of nasty Chinese soft wood (Chu wood I believe).

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 76 to 90 of 111

Thread: JW15 piece of shit

-

07-09-2021, 05:07 PM #76Member

- Join Date

- Sep 2014

- Location

- Southland

- Posts

- 1,509

-

-

07-09-2021, 05:26 PM #77Member

- Join Date

- Dec 2011

- Location

- Southern Alps

- Posts

- 5,703

My JW15 got chopped to 14inchs.Just over legal minimum legth from barrel tip to butt tip.Just check on that.

-

07-09-2021, 06:22 PM #78

I brought mine brand new when I was 16 as soon as I got my license.. Its never let me down..shot a few possums and deer with it over the years...Not the smoothest action, but still does the trick. Its a pity yours is that way!

-

07-09-2021, 09:36 PM #79Member

- Join Date

- Jul 2014

- Location

- BOP

- Posts

- 4,181

Can't remember when I bought mine had it that long,second hand wood/blued, haven't done anything to it other than shot, has shot thousands of pest animals and the only problem I had was it sometimes left a shell in the chamber after firing. Put new extractors on it and it's fine. I find that the chamber gets a bit grubby after a lot of rounds so I use a nylon brush and scrub the chamber out From time to time. Can't fault mine only paid about a $100 for which was a bit back when I got but it has been a reliable straight shooter. Shot a 12mm and 14 mm group at 25 yds with Power Point HV and a 19 mm group with the cheaper Bushman ammo a few weeks back.

-

07-09-2021, 09:37 PM #80Member

- Join Date

- Dec 2011

- Location

- Christchurch

- Posts

- 1,985

We've chopped, recrowned and polished action on about 20 JW15s and I really do rate them as worker 22s - as good as you'll get for the truck/quad. Almost all dropping under 0.5" at best at 50m after chop and recrown - even though bore often well off centre. Older ones often best, avoid GC ones and Polytech branded models - and from others comments it appears avoid latest GC Outdoor Arms models too.

The polishing and chop/recrown work takes about an hour or so - nothing too flash there. This brings out the Brno DNA and you have a deadly and efficient little hunter. Shot many thousands with mine.

-

07-09-2021, 09:53 PM #81

-

08-09-2021, 09:11 AM #82Member

- Join Date

- Dec 2011

- Location

- Christchurch

- Posts

- 1,985

No rocket science to polishing/improving JWs..

Main thing is to check action for burrs - remove any on bolt and inside receiver. Then get dremel and smooth out machine marks on bottom of bolt as it runs over sear - usually a bit rough there. Then you can either adjust trigger to suit, or disassemble and polish components if rough. Then check magazine - is ramp moving up and down smoothly. If not, slide off bottom plate, take out spring and ramp and polish edges. Check and if necessary polish also inside of mag to remove burrs. Reassemble and keep mag lubed - a little bit of CRC every 2-3 shoots keep them performing well. From time to time some may also need a tweak to top feed lips.

Barrel chop I think I've described elsewhere - pretty simple really. I cut barrel 15-16" from front of receiver, then finish cut with wet and dry. Then take a round headed brass screw - fit it into drill, apply lapping/grinding compound, and drill bore end to create new crown. When it looks good (use a magnifying glass if necessary), check with cotton buds to ensure zero burrs. Bit of blue on barrel end. We've done heaps with this chop and recrown method and it always works. And from every example I can think of it improves accuracy - the shorties almost all sub 0.5" at best at 50m.

As a wee feature you can also scallop top of bolt elbow flat to enable better scope bell clearance, then wet and dry sand (800-1200 grit) the bolt handle completely free of all blue. Then give it a polish with autosol and you have a neat little stainless look bolt.Last edited by mudgripz; 08-09-2021 at 09:20 AM.

-

08-09-2021, 11:35 AM #83

Larry is right, Norinco is the Chinese government's small arms exporting SOE. It is not a factory.

China has a lot of arms factories spread out over the its map - which is about the size of Europe. JW series rifles could be made anywhere.

EM332 was made in in the ErMei arms factory in Sichuan, someone told me that it had gone bankrupt about 10 years ago which is why EM332 is permanently discontinued. That would not have happened if EM332 was made by Norinco directly, would it?

-

08-09-2021, 02:36 PM #84Member

- Join Date

- Feb 2017

- Location

- Jafa land

- Posts

- 5,744

-

10-12-2024, 12:16 PM #85Member

- Join Date

- Nov 2019

- Location

- North Canterbury

- Posts

- 606

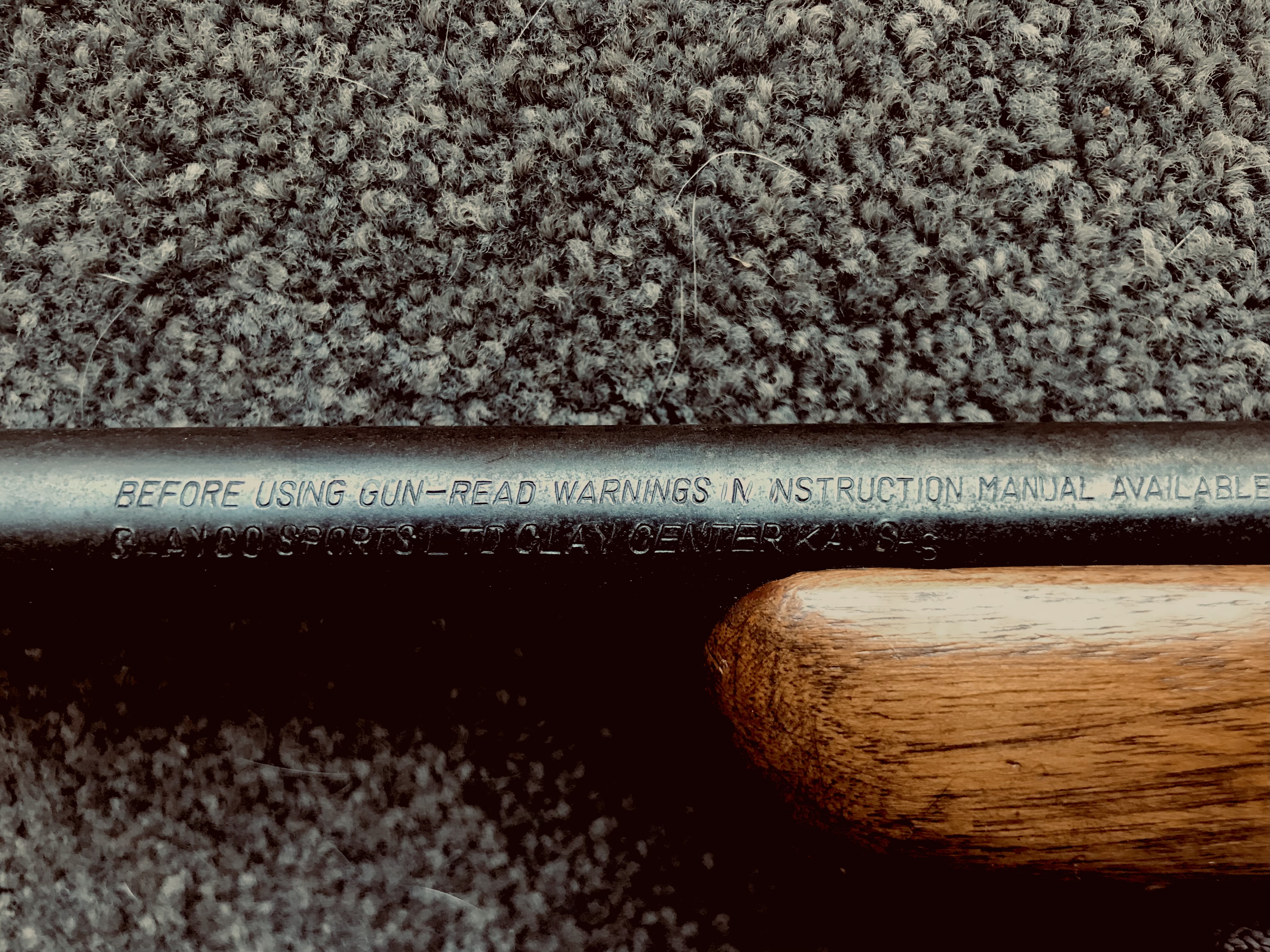

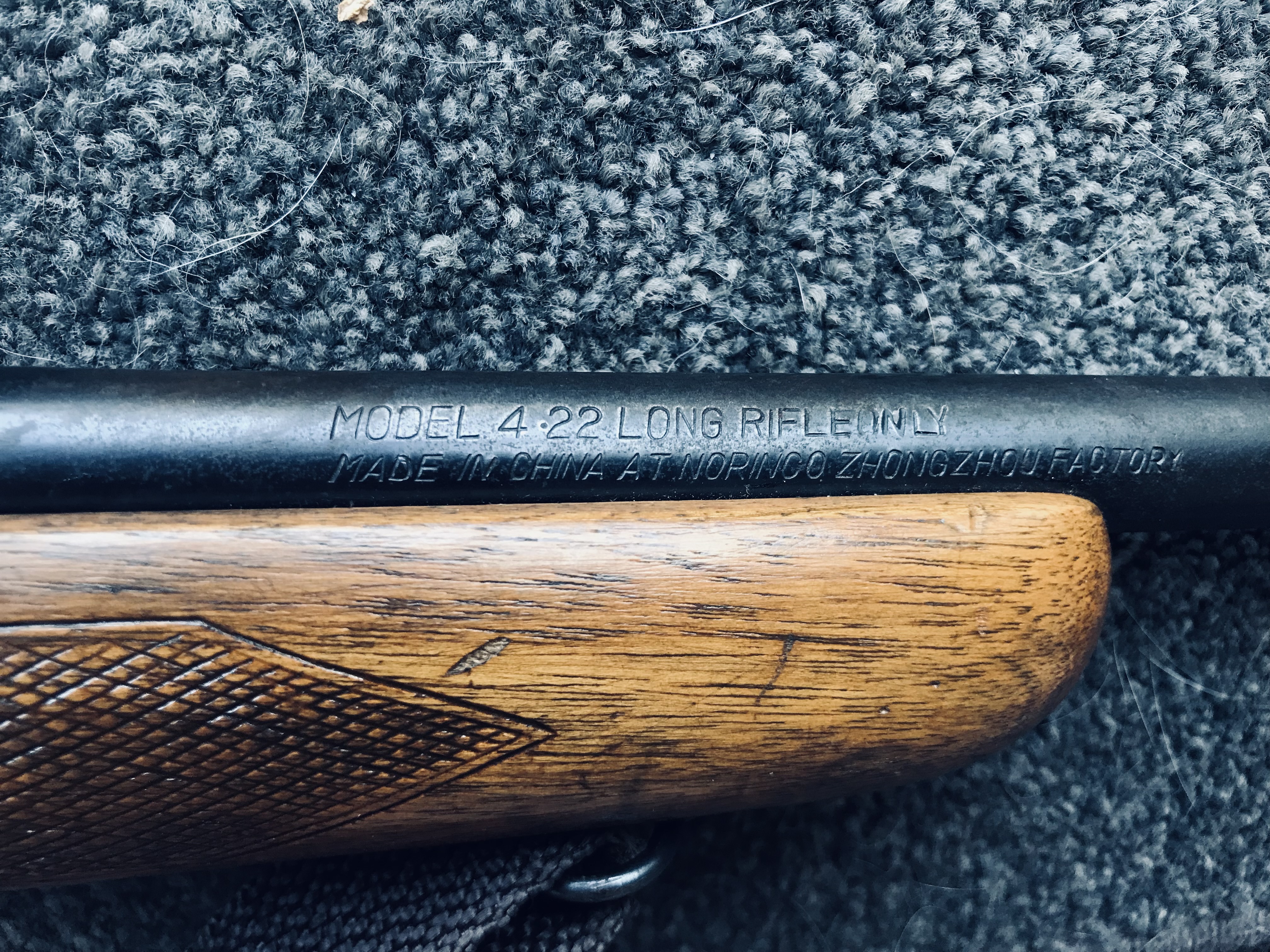

Norinco JW-15 (Early Import...Marked M-4 Clayco, Kansas) 22LR copy of Brno #1 22" Barrel jw15 off the site Has the early model double adjustable trigger, magazines are interchangeable with CZ 452. Looking

forward to seeing how it shoots its an oldie but feels good nice and smooth rifling looks good, not going to do anything to it until Iíve tried it out. Comes with a Cz mag.

forward to seeing how it shoots its an oldie but feels good nice and smooth rifling looks good, not going to do anything to it until Iíve tried it out. Comes with a Cz mag.

-

10-12-2024, 12:19 PM #86Member

- Join Date

- Nov 2019

- Location

- North Canterbury

- Posts

- 606

American import before Chinese arms were banned in the 1980s will see if there a piece of shit or not.

-

10-12-2024, 03:08 PM #87Member

- Join Date

- Nov 2019

- Location

- North Canterbury

- Posts

- 606

Norinco made in China here

www.zzmworks.com/product

Should have said JW Firearms made here.Last edited by RabbitStu; 10-12-2024 at 03:28 PM.

-

10-12-2024, 04:25 PM #88Member

- Join Date

- Aug 2019

- Location

- South Otago

- Posts

- 4,047

Why canít I access past page 6 of this thread??

ĎMany of my bullets have died in vainí

-

10-12-2024, 04:39 PM #89Member

- Join Date

- Aug 2012

- Location

- Otago

- Posts

- 1,759

-

10-12-2024, 04:41 PM #90Member

- Join Date

- Jan 2018

- Location

- kaiapoi

- Posts

- 7,881

There will be some people on here that commented back in the day that have been banned and the comments wiped

It screws up the pages

Similar Threads

-

Piece of shit fucking Redding Big Boss press!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

By stug in forum Reloading and BallisticsReplies: 42Last Post: 12-02-2017, 08:52 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

118Likes

118Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks