still waiting........

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 46 to 60 of 77

Hybrid View

-

24-07-2021, 02:59 PM #1

-

04-08-2021, 11:06 AM #2

I found a little time to do some work on this rifle again, so a small update.

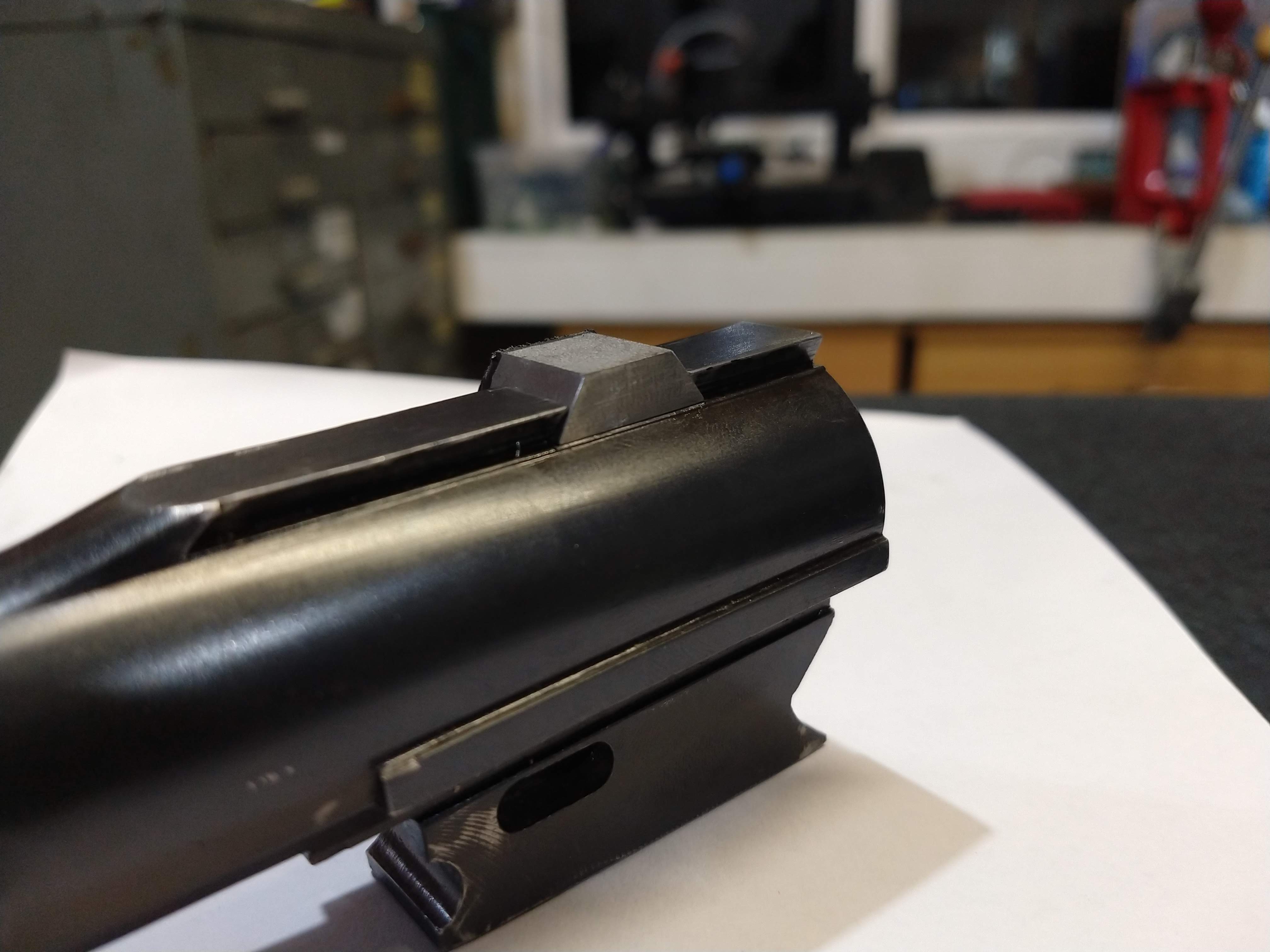

I have been working on sorting out the sights before I permanently fix the barrel in place.

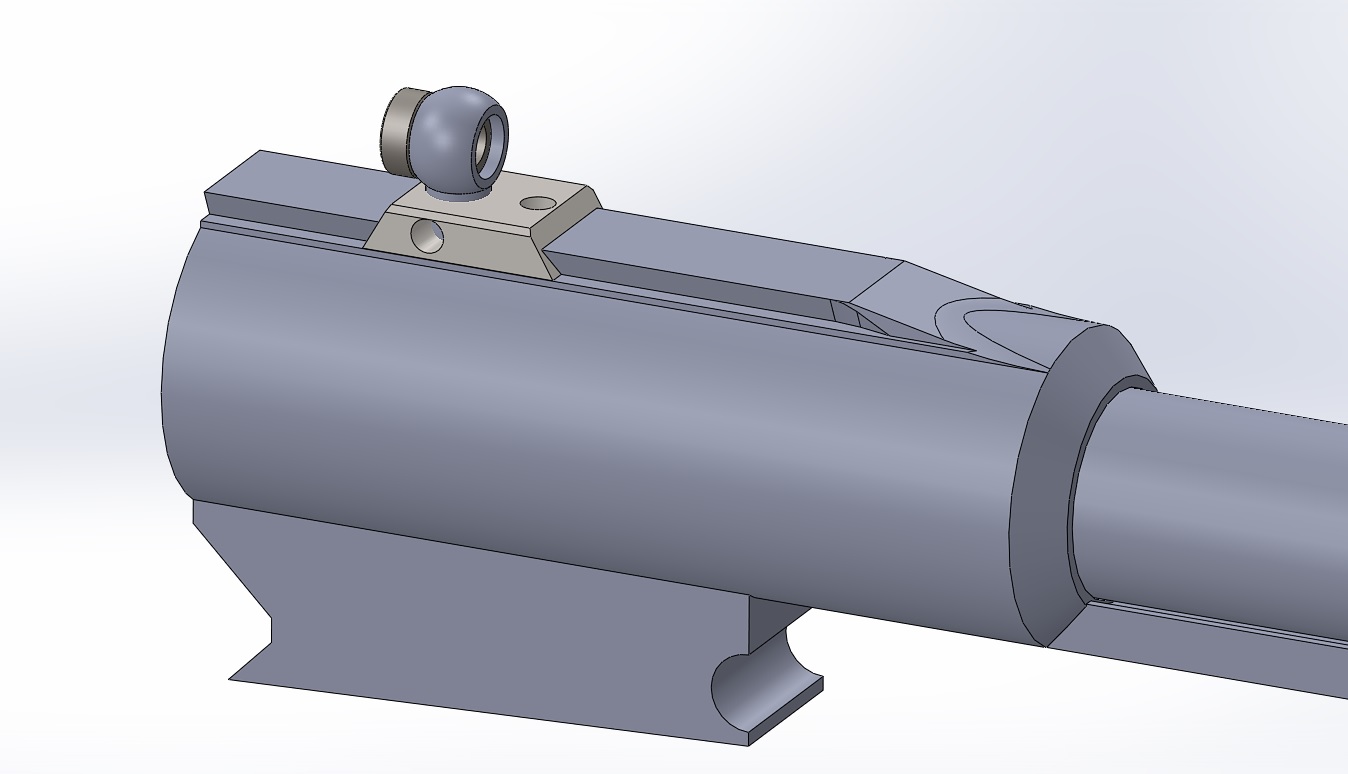

I ran through a few different designs for the rear sight and eventually settled on a simple and effective solution, which is to cut a dovetail 90degrees to the current top dovetail and have a removable insert the same is what is seen on a Skinner sight.

This means that I can still mount a scope if I want to by simply releasing the windage locking screw and sliding the whole sight block out one side. elevation change is done by screwing the threaded aperture mount up and down, this is locked by a grub screw. Windage is changed by sliding the block sideways and is also locked with a grub screw. My front sight will be adjustable for windage as well, so I should be able to zero the rear to a scribe line.

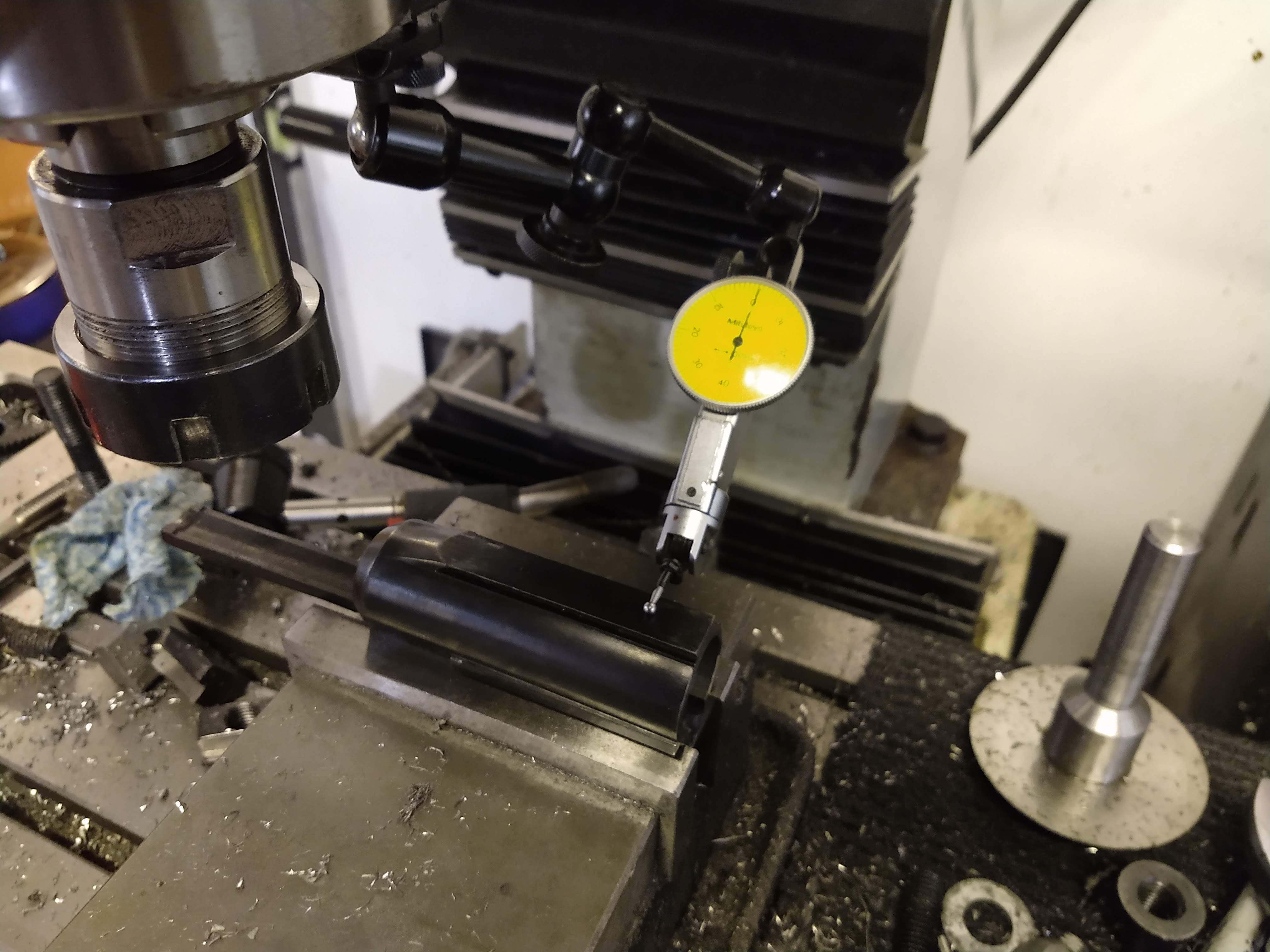

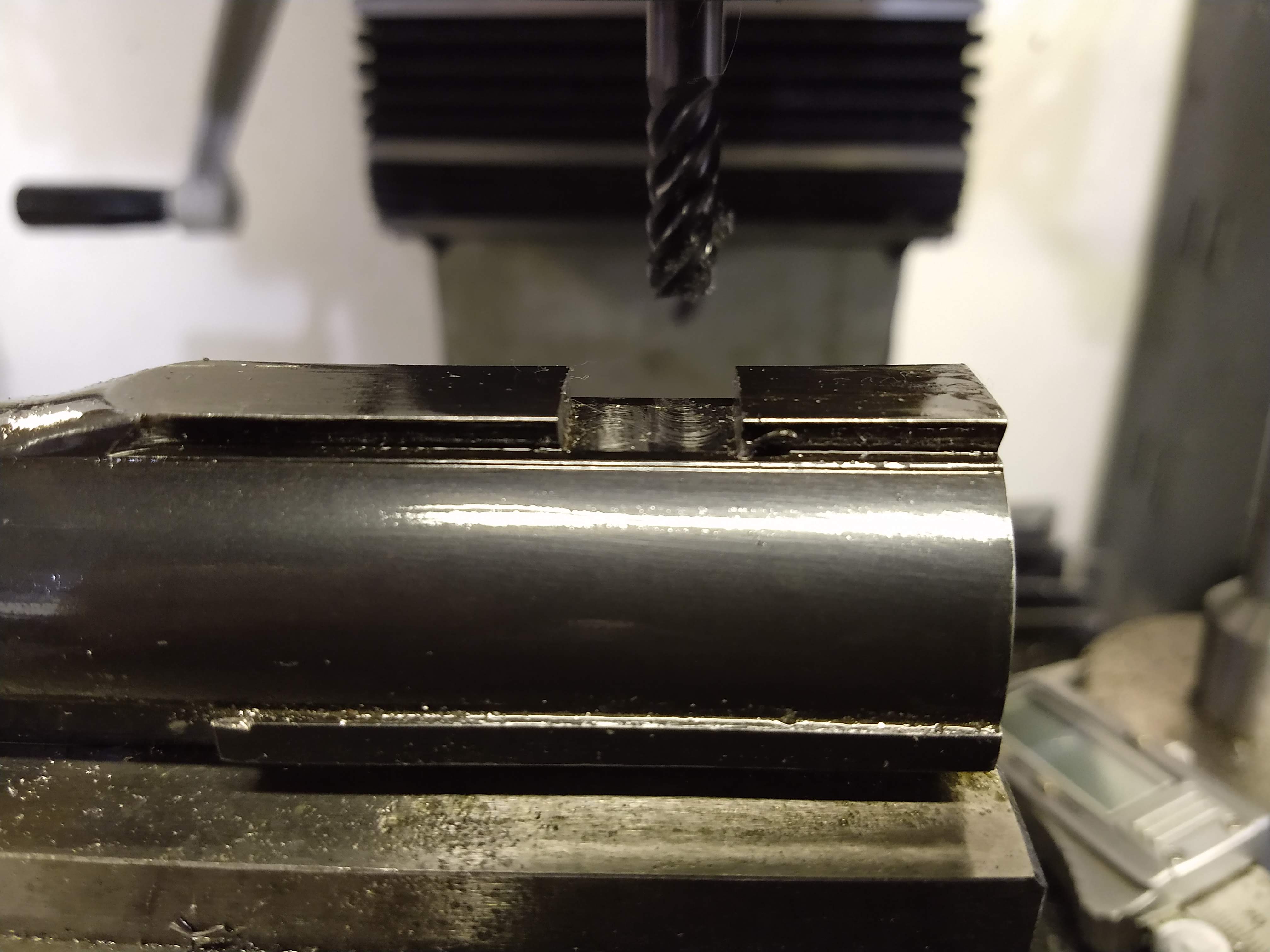

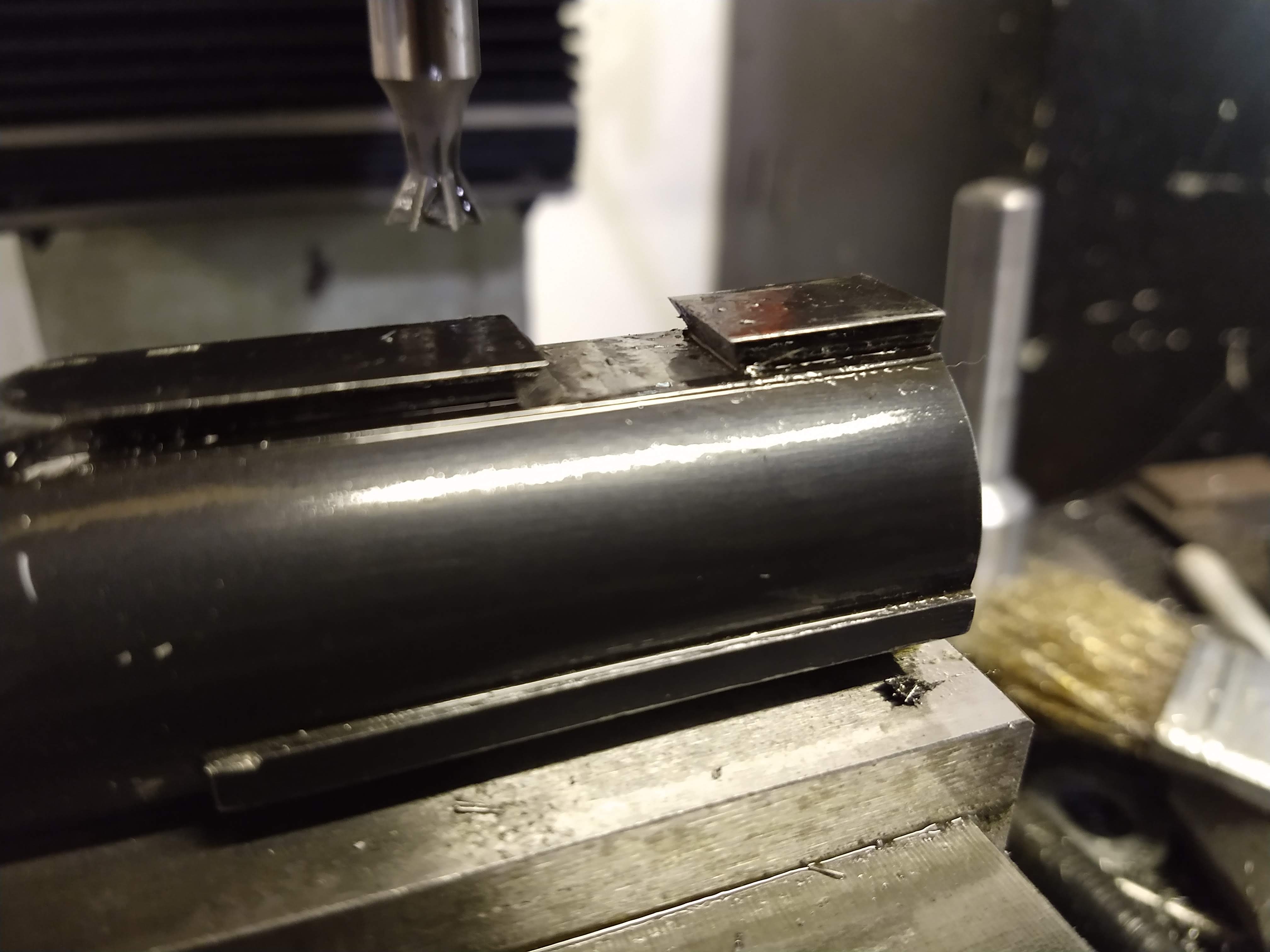

Cutting the dovetail in the barrel block was easy enough. I held it in the mill vice and used an indicator to check that the top rail was parallel to the table. I then cut the bulk of the material out with an end mill and cut the dovetail sides with a 60deg cutter.

After that was roughed out, I de-burred and smoothed everything out with a selection of stones.

Once that was finished to size, I started on making the sight mounting block. This is made from an offcut of 416 stainless, as it machines beautifully and I can bead blast it and not have to finish it otherwise.

I need to either make or buy a very fine tap for the sight elevation screw. Im thinking something like M6x0.5 or M5x0.5. TradeTools have an M6x0.5 tap for about $35, which while expensive for a single hole, would be smarter than spending an hour or two making and hardening a tap from carbon steel.

I also found this front sight block soldered to a barrel stub I had in my offcuts box. I need to change the underside radius to match my barrel and make a new sight post, then I can solder it in place once the barrel is installed.

I now have brass, dies, powder, a handful of projectiles and primers for this rifle, but the range test is still a ways off. Lots to do beforehand. So settle down Micky Duck! I will get there.

-

04-08-2021, 01:52 PM #3

-

07-08-2021, 04:19 PM #4

-

22-08-2021, 02:39 PM #5

Seeing as I have been stuck at home for the last week, I managed to find some time to work on this rifle.

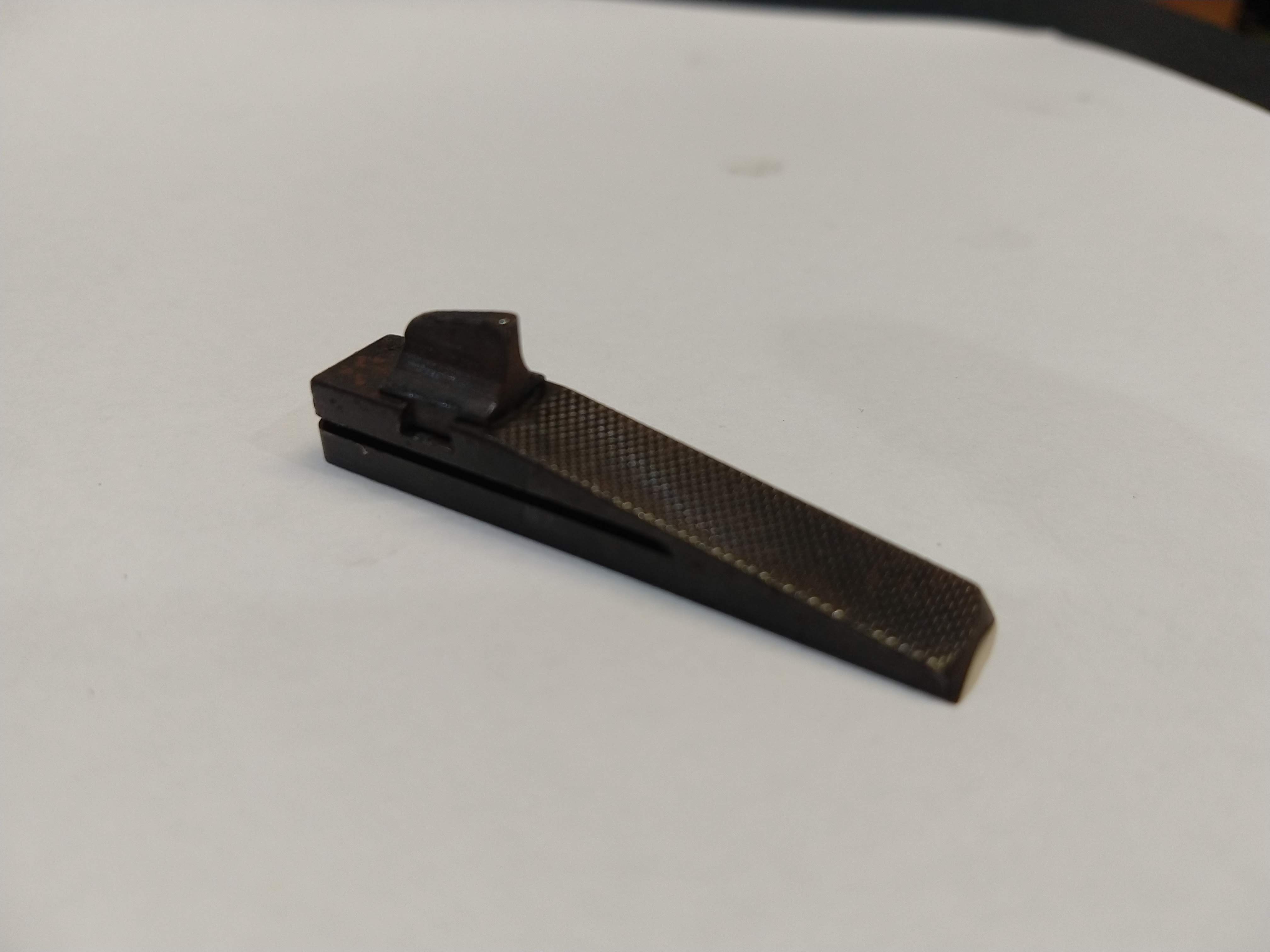

I finished off the sight block and made a aperture holder to screw into it. I am likely going to have to make this again, as the threaded hole for the aperture is not dead center on the threaded post that goes into the block. Meaning that if I rotate it 180degrees, the windage will change along with elevation.

I also made a quick aperture insert from an M6 capscrew. I will experiment with different sizes and designs once I start shooting it.

I cold blued the barrel and it came out way better than I expected. Turns out 4140 takes cold blue really well. The most important thing I have found is having the metal extremely clean before starting. I use CRC Brake Clean to degrease and then Acetone.

I ended up gluing the barrel in with JB Weld, as I am not that confident in my soldering skills to do a nice neat job. I also decided to glue the front sight base on with JB Weld. Time will tell whether this is a good idea or not. With proper joint prep, it should be more than strong enough.

I used a machinists level to align the top face of the sight with the dovetail rail and marked its position. I then masked off and prepped the area for bonding. A good sand, brake clean, then acetone.

The sight base was held in place using a spring clamp and the joint cleaned up.

Once that was cured overnight in the hot water cupboard. I decided that I wanted to make the dovetail in the front sight block larger. This would have been much easier to setup before it was glued to the barrel.

I did not have any dovetail cutters small enough, so I ordered a couple from ebay and then decided I couldnt wait that long and made my own from some 6mm Drill rod. It was a simple case of turn the correct profile on the lathe, polish, harden and temper the blank, and then grind it exactly in half on the surface grinder. I then manually added some relief to the bottom face and cutting edge. It worked surprisingly well and only tool about an hour to make. A good skill to have in a shop like mine.

With the sight block dovetail finished, I could start on the front sight itself. I milled this from a block of O1 tool steel as the post is only 1mm wide and I wanted to harden it so its not easy to damage. I got lucky and got the dovetail fit perfect with only a couple of passes. Its a good firm fit that needs to be tapped into place with a punch, but doesn't need bashing. Once I had the dovetail cut, I removed it from the rest of the block and milled the post to size. I left it long initially and once it was on the rifle, I carefully measured the final required height and cut it down, I also milled a very small v into the top of the post to help align the bead.

After I hardened and colt blued the front sight I added a brass bead to the top. I have some fiber optic rod on the way, but this will do for now. The brass is about 1.4mm diameter and seems about right, maybe a touch too large.

I have been working on the leather buttstock cover today. Once its finished, I will post some more photos.

-

27-08-2021, 06:50 PM #6

I have finally finished this "quick side project" more or less. I just need make a thread protector and to get a load that shoots ok. Bit hard at the moment being stuck in the middle of the suburbs. I will also make a suppressor for it at some point, but I have other things I need to work on for the moment.

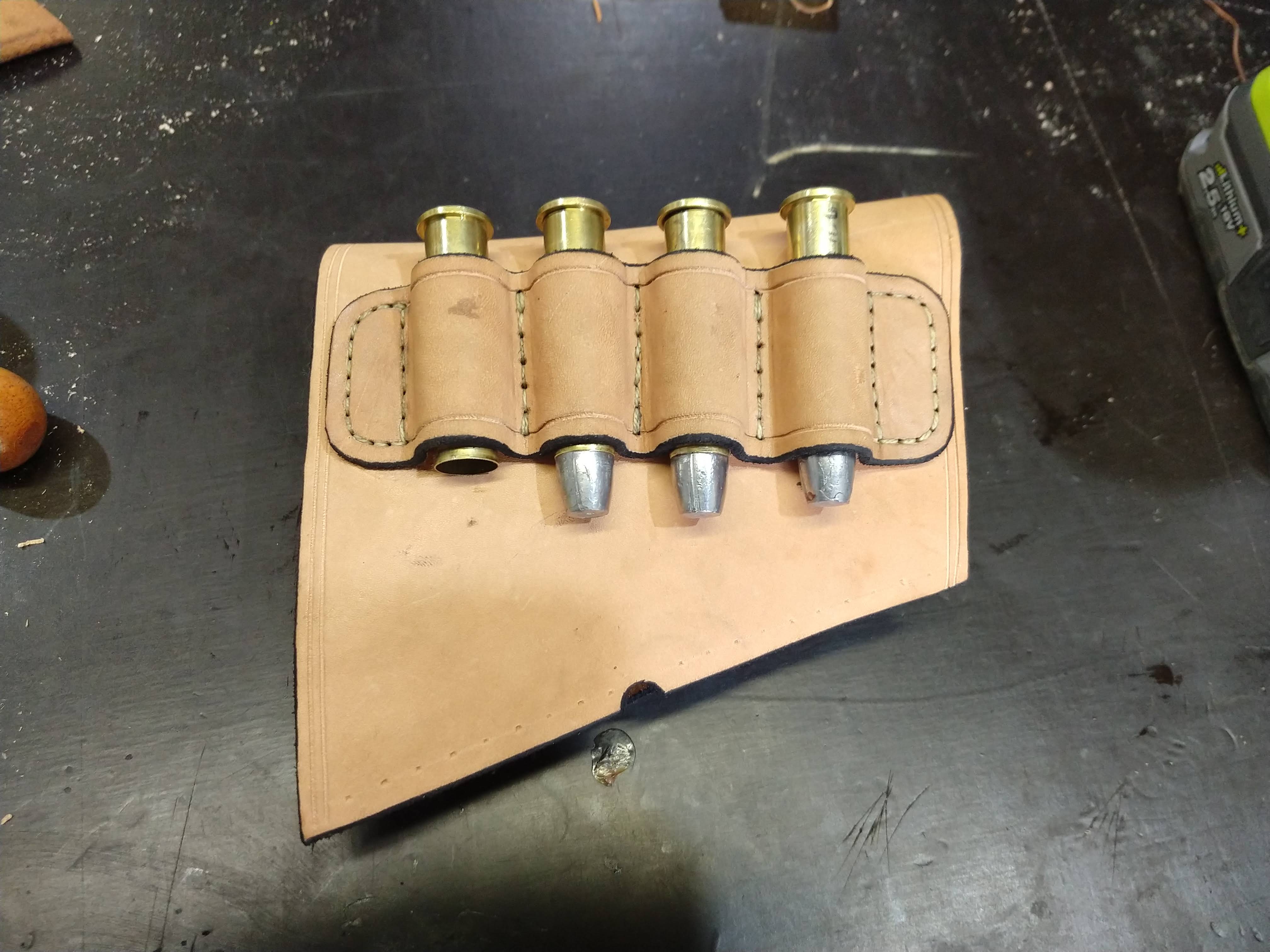

I decided to make a leather buttstock cover and cartridge holder. I am no leather worker, I picked up a bit of the skill making knife sheaths for the knives I was making and selling, but I was never that interested in it and never got very good. Saying that, im pretty happy with how it came out.

I made a quick pattern from paper to get the overall profile and then cut that and made a strip for the cartridges that I soaked in hot water and formed around some cases.

I left this to dry overnight, then glued and stitched it to the body.

After that, I added some edge black and soaked the whole thing in neatsfoot oil.

I then attached it to the rifle using a baseball stitch. easy to get off, just cut the stitching, but a pain to put back on, so I added a reasonable amount of stock wax underneath the leather to hopefully delay the need to remove it.

And this is the final product. Bang on 3kg with 4 cartridges. Hopefully it shoots well enough to hit something within 80m.

Thanks for looking.

-

29-10-2021, 11:16 PM #7

ok...range report is still missing...time for an update LOL

if I havent said it before...that is a plurry neat job you have done.......

-

30-10-2021, 05:16 AM #8Member

- Join Date

- Nov 2014

- Location

- Central Otago

- Posts

- 2,348

It will be a thumper to shoot!

-

27-12-2021, 10:52 AM #9

I had a chance to put 3 rounds through this a few weeks ago. I did not have a chronograph and it was only 3 rounds as I was not expecting to have an opportunity to shoot it given the location.

The loads were a combination of 410gr projectiles I purchased from ShooterNZ here on the forum and 450gr projectiles that I am making myself.

The load for both was 15-16gr of ADI AP100 with about 0.8gr Dacron filler. I have been learning all about case mouth flaring and expander mandrels, as to this point all my loading has been for boat tail jacketed projectiles, so a bit of a learning curve to deal with cast bullets well. Quickload estimates this load to be right on 1000fps.

Recoil was stout but not obnoxious. I would liken it to my lightweight and short 308 hunting rifle shooting hot loads. With full house 45-70 rounds I think it would be extremely unpleasant to un-shootable. It is only 3kg after all.

To my surprise, my efforts seemed to pay off in drawing the projectile path and barrel/barrel block in CAD to work out exactly how high my front sight and rear sight needed to be. It was shooting approx 2.5" high at 25m and good windage, which is close to what it should be to give a zero of about 80m and then around 3.5" - 4" drop at 100m.

I have been playing around with making a mold for casting my own 450gr projectiles. It took a few goes to get one that would fill out and eject the bullet properly. It is not a split mold and is along the lines of paper patch bullet molds since it does not need lube grooves as I am powder coating. I need to remake the sprue plate and make a decent handle for it, but I managed to cast enough for testing.

I have 20rds loaded up ready for some proper testing once I find somewhere to shoot. I lost access to my last spot about 6 months ago as the property was sold

-

31-01-2022, 10:01 PM #10

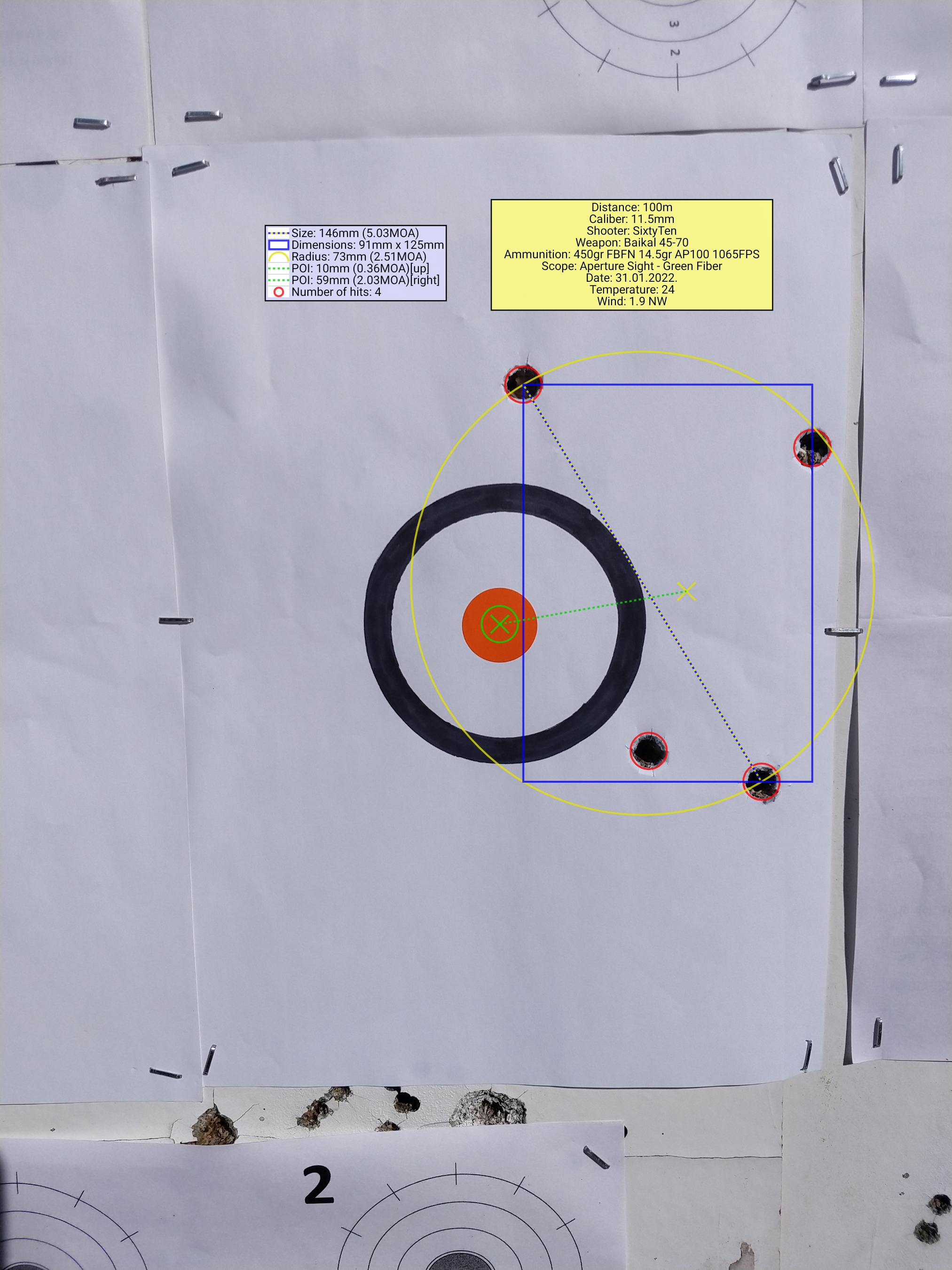

I had an opportunity to shoot this properly today. Unfortunately, only at 100m, which is not ideal for a rifle like this, with sights like this and eyes like mine. Saying that, I shot at a 10" gong for the first round and smacked it good, much to my surprise. I then moved to paper and shot 4 rounds of my 450gr projectiles and got a "group" of around 5moa, which I am very happy with. I could only barely make out the target ring as the sun was heading down and directly on the target. The sights seem to be pretty close at 100m, more than good enough for a rifle like this, which I don't intend to shoot further than 80m or so. Velocity averaged around 1060fps, so I might drop 0.2gr to keep it consistently subsonic.

Load was;

Hornady brass trimmed to around 1mm shorter than standard

Custom 450gr projectile, powder coated and sized to 0.463

14.5gr AP100

1.0gr Dacron Fill

Random primers from the bottom of my reloading drawers.

The next stage for this rifle is to make a suppressor for it. I can go to around 40-41mm before it starts getting in the way of the sight picture and I will keep it fairly short at 160mm or so, it will likely be aluminium tube and baffles and I will probably glue it together rather than threading to keep the weight and complexity to a minimum. The goal of this is not to have a mouse fart gun, but something that can be shot without hearing protection and not have the far-reaching sonic crack of high velocity cartridges so it can be used in less than rural areas when less noise is needed.

I am moving my house and workshop over the next couple of weeks, so nothing will be done for a while.

-

23-06-2022, 06:17 PM #11

I had good intentions and THOUGHT my bush shots would be 25-50 yards...but the other day I got 3 oppertunities and none were less than 75yards...2 clean misses at 100ish yards 2-3 hours apart....yeah nah.....have bodgied up a scope attachment...will see how we get on when its cured....

have you tried this again???75/15/10 black powder matters

-

23-06-2022, 06:41 PM #12

Same with me, my last "bush" shot opportunity was 310m. Luckily I was carrying a mates 6.5CM with a range finder and drop indicator built into the scope. About the easiest possible way to shoot 300m.

I haven't had an opportunity to shoot this again between moving house, organizing my workshop and now the cops are dragging the chain on my renewal and I have no license or firearms at the moment. I applied over 7 months ago.

-

23-06-2022, 06:48 PM #13

Im pretty sure if you made up some more wee apertures that fit onto dovetails...both sizes and could keep the cost down,they would be rather popular and sell like hot cakes...

75/15/10 black powder matters

-

25-06-2022, 12:34 PM #14

The problem is in keeping the cost down. Aperture sights (even very simple ones) are fiddly things to make. I would have to charge in the region of $150 for them to be worth my time, and even then I would not be making much, if anything. Unfortunately that's just the reality of manual machines and small scale.

For Baikal's in particular, you would need much higher than standard front sights as well if the aperture was sitting on top of the dovetail.

Its a good idea, and there are bound to be people interested in the product, but probably not for the price tag that would be necessary.

-

25-06-2022, 01:47 PM #15Member

- Join Date

- Jan 2020

- Location

- porirua

- Posts

- 854

Similar Threads

-

New Baikal 121 Single Shot out

By Scout in forum Firearms, Optics and AccessoriesReplies: 15Last Post: 28-11-2020, 12:35 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

105Likes

105Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks