I got a very nice Winchester 1885 25 RF recently.

Circa 1910

Very good condition mechanically and an excellent bore

Original idea was chamber 25-20 and convert to center Fire.

But it's so original I decided to try making my own rimfire brass !

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 15 of 48

-

14-04-2023, 11:37 PM #1Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

Making 25 rimfire reloadable brass

-

-

14-04-2023, 11:44 PM #2Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

First job was to test fire with vintage black powder 25 RF ammo

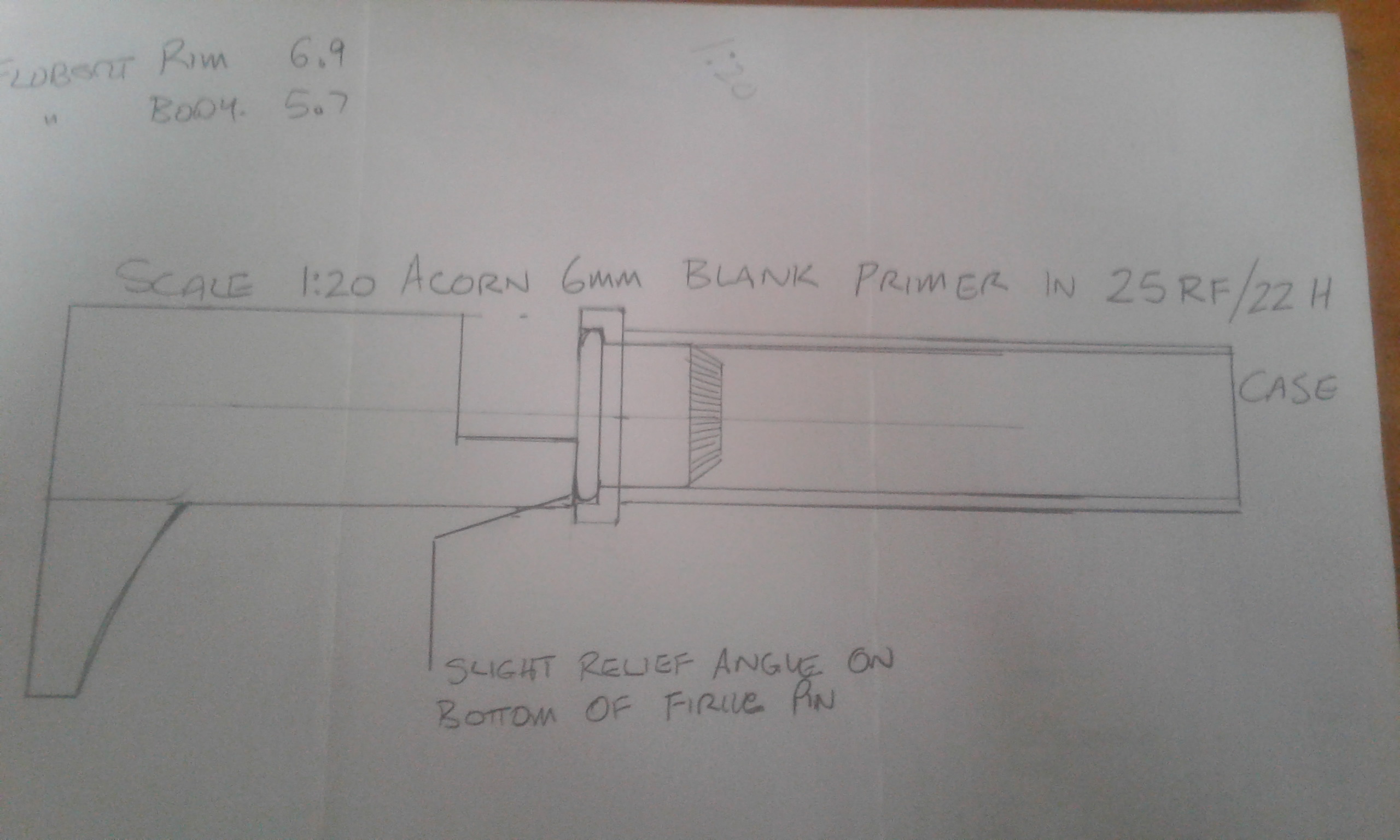

Then plan it out the case to take acorn caps as RF primers

Check the RF firing pin

Make a case from 22 hornet brass

Test it for firing pin strike

-

14-04-2023, 11:48 PM #3Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

So now I want to go live fire

Parted off 3x 120 grain 257 bullets to around 60 grains

Sit them on 2.0 grains of trailboss

First shot low and sub sonic

Correct rear tang sight

Next 2 shots in the bull at 35m

So proof of concept with 3 or 4 cases made.

Turn out 25 serviceable cases

-

14-04-2023, 11:56 PM #4Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

So today a bag of bullets arrive courtesy of a kind forum member

67 grain Lyman

75 grain NOE

85 grain

Straight to the workshop

67 grains over 2.5 grains of trailboss

First 3 shots 12mm at 40m

And supersonic

Try the same powder under the 75 grainers and much more open groups

So back to the 67 grainers and sub 20mm 40m groups all the time

Reloaded the 3 cases 5 times with one case split but no drama

-

15-04-2023, 12:02 AM #5Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

Put together 5 rounds to go for a late afternoon hunt

Shot this hare at 45m

Straight through the top of the heart and what a lot of damage

So this evening I have done myself 10 rounds

But I have to ease up as I'm already short of 67 grain bullets

But the good news is a good friend has brought me a Lyman 67 grain 257 bullet mould and I expect it will be the same model as the one that made these bullets

-

15-04-2023, 12:06 AM #6Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

So if anyone wants to get a vintage 25 RF shooting good clean safe new RF ammo I can show them how to do it

BUT it is not easy to make the brass

And I have spent a stupid amount of time on these tiny little rounds

And it was still worth it to have a very collectable rifle that I can shoot as an every day carry !

-

15-04-2023, 08:22 AM #7Member

- Join Date

- Jul 2022

- Location

- WANGANUI

- Posts

- 238

25 acp brass

Hi great job in making food for the ole girl

i am building a 25 acp single shot and wish to know how to change the 22 hornet brass to 25 acp

or find some empty 25 acp brass .

Have you thought of using 25 cal air gun slugs 25cal x 44 grains RN solid lead they can be bought from from Amerzon

Cheers AR7

-

15-04-2023, 08:37 AM #8Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

@AR7 Making 22 hornet brass to 25 hornet is really easy.

But then I used a 25 ACP carbide sizer die to take the body taper down to the 25 RF diameter. This only partly works because the sizer doesn't go to the rim of the case due to the thickness of the shell holder

I have some 36 grain cast airgun pallets coming from within NZ. But I realistically expect them to be undersized because 25 air rifles seem to run about a .254" groove.

But you never know.

Well if I were doing a single shot rifle like you mentioned I would be using a case with a rim. The 25 ACP is going to be very tricky to make a rimless extractor for.

The 25 hornet or a wildcat based on Hornet brass that doesn't need a huge amount of modification would be nice.

The up side of a single shot rifle is once you have made 100 cases you are unlikely to loose them as you would with a repeater

-

15-04-2023, 09:38 AM #9Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

@AR7 Thinking about your project I think if it was me doing that single shot I would run with the 25 ACP chamber and leave the 22 Hornet case rim on it.

Cut the chamber

Cut the rim rebate for head spacing rather than the mouth of the ACP case

Better brass with less removed

Better extraction

Way easier extractor to build and 100% reliable

With the limited capacity of the 25 ACP chmber these would be everlasting cases

-

15-04-2023, 09:47 AM #10Member

- Join Date

- Mar 2023

- Location

- Central South Island

- Posts

- 660

Excellent work and clever thinking! Over the years I have seen and been offered several of these rifles, but never bothered to take it any further cos ammo was almost impossible to obtain. Then if you did find a box of genuine rimfire ammo, you needed to find another box as soon as you shot them all off. Cool wee rifles.

-

15-04-2023, 09:53 AM #11

great work!

‘Facts don’t care about your feelings’

-

15-04-2023, 09:56 AM #12Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

-

15-04-2023, 10:18 AM #13Member

- Join Date

- Aug 2012

- Location

- helensville nz

- Posts

- 4,744

well done and good thinking mate

i think your vintage 22lr's have just become redundant.

-

15-04-2023, 10:19 AM #14Member

- Join Date

- Dec 2014

- Location

- canterbury

- Posts

- 6,994

-

15-04-2023, 10:40 AM #15Member

- Join Date

- Aug 2012

- Location

- helensville nz

- Posts

- 4,744

Similar Threads

-

Making 7mm-08 brass

By Dicko in forum Reloading and BallisticsReplies: 7Last Post: 20-09-2020, 01:19 PM -

Making 300 Blackout Brass. Neck Diameter Issues.

By Simon in forum Reloading and BallisticsReplies: 2Last Post: 24-12-2014, 09:43 AM -

Federal making 300 RUM brass

By 7mmsaum in forum Reloading and BallisticsReplies: 7Last Post: 14-08-2012, 08:22 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks