Gidday,

Loaded up some rounds for mates 300wsm.

Norma brass (new)

FED match magnum primers

2209

178 ELDM

Tikka T3X 20” barrel.

61.5 gr start load, up to 63.5gr max at 0.5 increments.

See attached photo of brass at max charge. Primers look bloody good but there’s swipes and ejector pin marks. I wasn’t there at time but he said he was getting sticky bolt on the odd shot before even reaching max charge. For me, it normally happens on the third shot.

I’ve run into this many times with Tikkas and Norma brass. I’ve only seen the max charge brass, need to look at the rest of the loads.

Would be keen to hear everyone’s thoughts and if they’ve run into this before. Could the chamber heating up cause pressure?

Best was the the hottest load that he shot at 63.5 gr book max. He pulled last shot apparently.

63.5gr

2860

2859

2873

S-D 7.4

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 1 to 13 of 13

15Likes

15Likes

Thread: Soft brass. Random sticky bolt

-

03-03-2023, 09:06 AM #1Member

- Join Date

- Nov 2012

- Location

- NI

- Posts

- 1,331

Soft brass. Random sticky bolt

-

-

03-03-2023, 09:11 AM #2Member

- Join Date

- Nov 2012

- Location

- NI

- Posts

- 1,331

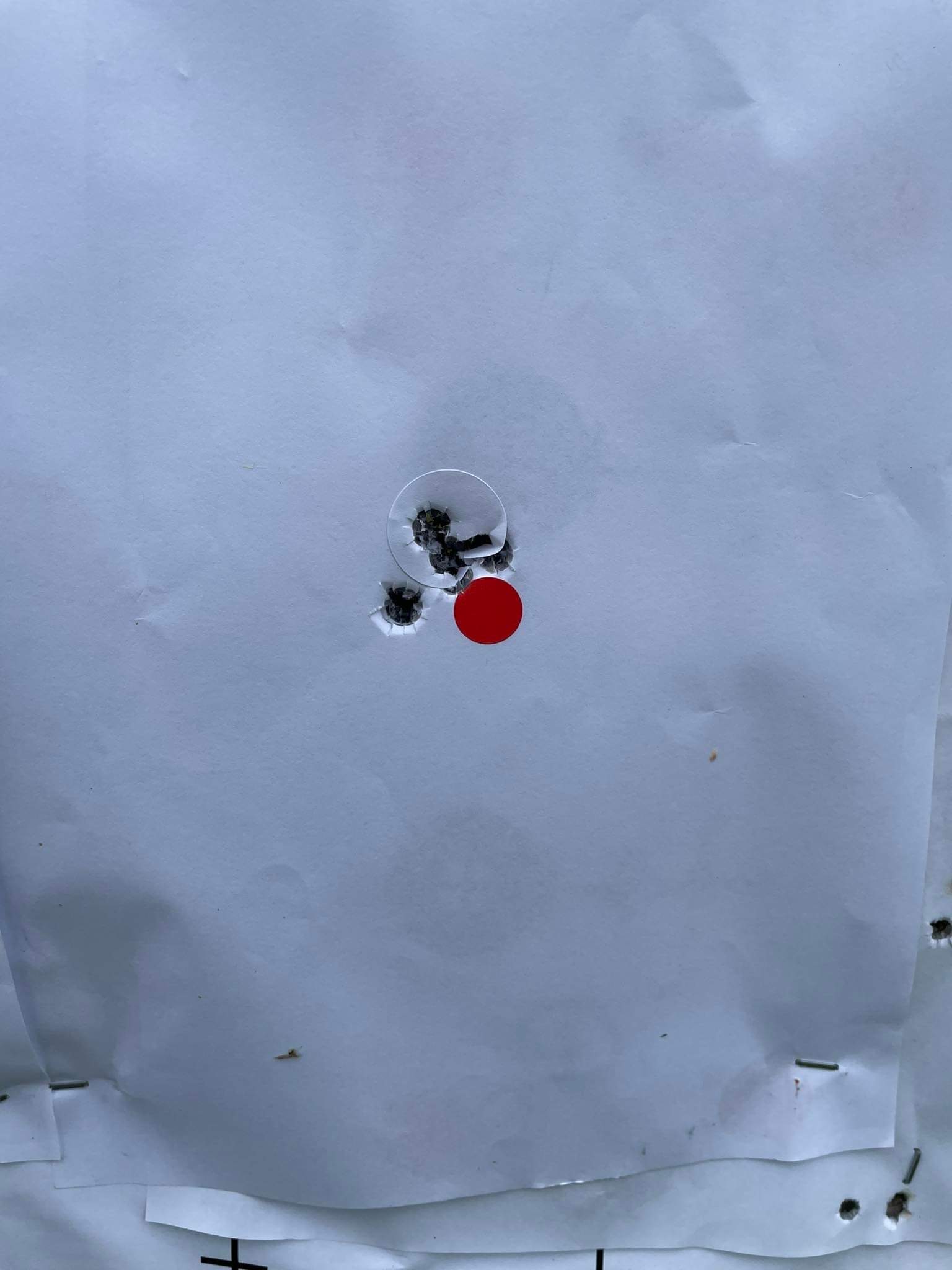

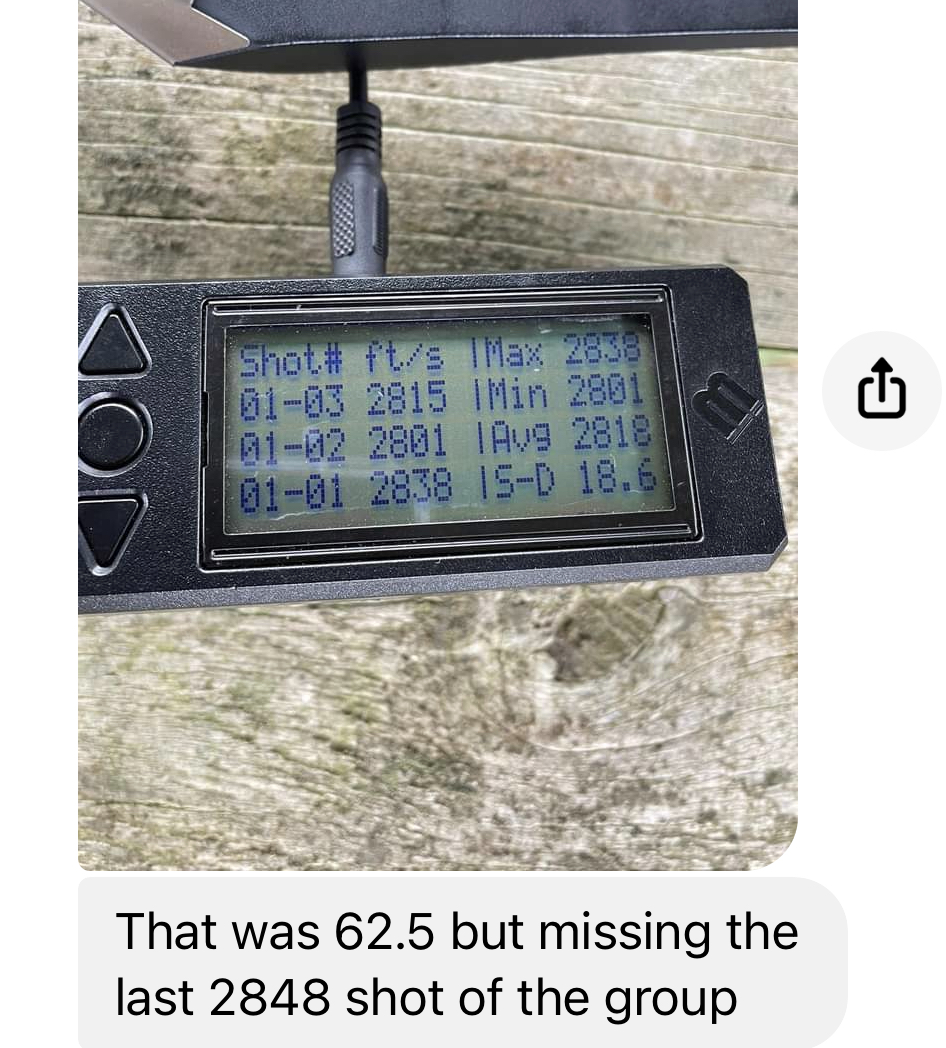

Have just got 62.5gr data from him.

Four shot group

-

03-03-2023, 09:13 AM #3Caretaker

- Join Date

- Dec 2011

- Location

- Hawkes Bay

- Posts

- 8,858

Powder burn rate too fast

Slow down a burn rate or two

That’s acceptable velocity and accuracy for hunting out of a short tubeA big fast bullet beats a little fast bullet every time

-

03-03-2023, 09:44 AM #4Member

- Join Date

- Nov 2012

- Location

- NI

- Posts

- 1,331

Yes, bloody good accuracy. And plenty fast enough.

2209 seems to be such a common powder for the caliber.

-

03-03-2023, 10:15 AM #5Member

- Join Date

- Jan 2023

- Location

- Yorkshire/England

- Posts

- 77

A couple of suggestions that may be worth a try .

Measure the web adjacent/close to the case head , if there's 0.001" expansion when compared to a new case its over pressure . I believe accepted expansion is about 0.0003" .

Alternatively, measure case volume of a fired case and enter all the load details into GRT to get a predicted pressure .

Norma brass is regarded as good quality brass , it may have lower case capacity than that used in development of data you're using . Unless it's Normas' data , in which case I now look foolish. Meh , what tthe hell, you don't know me 😇

-

03-03-2023, 10:46 AM #6Member

- Join Date

- Dec 2011

- Location

- Te Awamutu

- Posts

- 849

I had exactly these symptoms in 6.5PRC when I changed to a resizing lube which was more greasy and my normal wiping on a cloth didn't clean it off properly.

I would recommend cleaning the brass with a paper towel and denatured alcohol and make sure there is absolutely no residue of anything on the case. Then swab the chamber with dry patches thoroughly as cleaning oil in the chamber can have this same effect.

Then try and see if the problem persists.

The lubed cases mean the brass doesn't grip the chamber wall and you experience excessive bolt thrust despite normal pressures. This causes brass flow at the case head. Hence the ejector marks and swipes but primers show no pressure signs. Not that I would use primers as a reliable gauge of pressure but they are part of the puzzle in problem solving here.

I went from experiencing what I would have thought were dangerous pressures at starting load due to sticky bolt lift and ejector marks to no ejector marks and light bolt lift and ending my load development with a 10% higher powder charge weight with still no pressure signs just by more fastidiously cleaning my brass post sizing.Last edited by Makros; 03-03-2023 at 10:52 AM.

-

03-03-2023, 11:04 AM #7Member

- Join Date

- Nov 2012

- Location

- NI

- Posts

- 1,331

-

03-03-2023, 11:11 AM #8Member

- Join Date

- Dec 2011

- Location

- Te Awamutu

- Posts

- 849

Last edited by Makros; 03-03-2023 at 11:32 AM.

-

03-03-2023, 11:18 AM #9Member

- Join Date

- Nov 2022

- Location

- Auckland

- Posts

- 555

I had a similar issue with new norma brass also, but in my .308, was getting ejector stamp / heavy bolt at 2800fps no where near book max powder charge when i was expecting to see closer to 3000fps at max charge. Primers looked great. Switched to lapua brass and im now at 2960 with a ever so slightly flattend primer and no signs of pressure on the brass at all.

-

03-03-2023, 11:59 AM #10Member

- Join Date

- Nov 2012

- Location

- NI

- Posts

- 1,331

-

03-03-2023, 02:13 PM #11Member

- Join Date

- Nov 2018

- Location

- Matamata

- Posts

- 1,757

Load some more at 62.5 and see what happens

-

03-03-2023, 03:59 PM #12

By the time they get smashed in to the bolt face a few times they will harden up.

"Hunting and fishing" fucking over licenced firearms owners since ages ago.

"Hunting and fishing" fucking over licenced firearms owners since ages ago.

308Win One chambering to rule them all.

-

03-03-2023, 10:54 PM #13Member

- Join Date

- Jun 2019

- Location

- Manawatu

- Posts

- 1,078

Yeah keep going with the same charge weight, clean the outside of the brass with isopropyl alcohol, if your primers are round on the edge you'll be fine. Had similar problem with Norma brass in my 6.5 PRC, had ejector marks from factory ammo, couple more firings and no new marks. That's plenty fast for that length of barrel too, a smokin load.

Similar Threads

-

Sticky bolt after second shot

By Kimber 7mm-08 in forum Firearms, Optics and AccessoriesReplies: 13Last Post: 02-02-2022, 11:11 AM -

Remington 700 sticky bolt dry fire

By Huey in forum Firearms, Optics and AccessoriesReplies: 14Last Post: 22-09-2021, 07:32 PM -

Sticky bolt?

By kiwijames in forum Reloading and BallisticsReplies: 60Last Post: 23-03-2020, 08:07 PM -

Sticky bolt.

By puku in forum Reloading and BallisticsReplies: 13Last Post: 12-03-2016, 06:35 PM -

Sticky T3 bolt

By Philipo in forum Firearms, Optics and AccessoriesReplies: 18Last Post: 09-09-2014, 08:58 PM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks