This has to be the most interesting thread on this forum, I find myself hanging out for updates on it

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 46 to 60 of 274

-

10-11-2014, 03:13 AM #46Using Tapatalk

-

-

10-11-2014, 07:16 PM #47

Well there you go guys, I`m doing the rifling now ,so you have caught up to me. Things are going to be a bit slower, but if anyone has any questions just ask and I`ll get back to you .Cheers, Homebrew.357.

-

10-11-2014, 09:35 PM #48

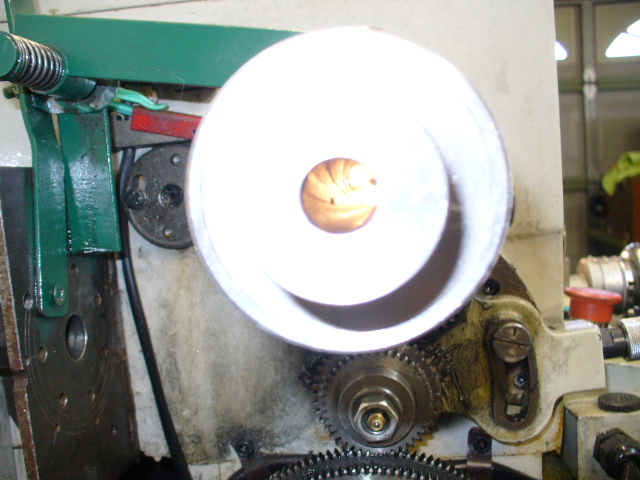

OK, the rifling is under way, I start at the breech end of the barrel, it has a slight taper machined in the bore to stop cutter from grabbing, the bore is well oiled and the cutter is raised to bore size for the first cut. The r/rod is cranked slowly through the bore and you can feel it cutting , when to comes out the muzzle there are fine chips on the cutter, that means I`v got it right.

,Homebrew.357.

,Homebrew.357. , Ready to start.

, Ready to start.  , The T/C cutter doing it`s job.

, The T/C cutter doing it`s job.  , The cutter is down, to lift the end bit is pushed in.

, The cutter is down, to lift the end bit is pushed in.

-

10-11-2014, 10:31 PM #49Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,248

home brew ,mate youre a bloody DIY genius! listen ive got a few B&S powered lawn mowers down the back-any bloody chance you could rip em apart and build me a 105mmpack howitzer.not takin the piss bud ,just sayin as like my mates say I couldnt hit a cows arse with a shovel with my 12g at present.

Im relishing the pictures when this wee project is finally bought together!keep up the marvellous work!

-

11-11-2014, 06:53 AM #50

no questions from me , just awe , sprockets and chain on the lathe , skill saw blade bits as cutters .,his some kind of sorcery !!!!!! .... this sort of "can do" attitude is being eroded from NZ culture ... I love it , the sad thing is , once some of you old boys kick it , the knowledge is gone for good ,the young fellas learning cnc machining would be fukked if they had to do this , well done homebrew

NO MATTER HOW MUCH IT HURTS, HOW DARK IT GETS OR HOW FAR YOU FALL , .....

YOU ARE NEVER OUT OF THE FIGHT . (Marcus Luttrell)

-

11-11-2014, 06:53 PM #51

How long does it take to do one pass with the cutter?

10MRT shooters do it 60 times, in two directions and at two speeds.

-

12-11-2014, 05:22 PM #52

Hi, It`s like riding a bike I suppose, the faster you crank, the faster you go, but I just crank nice and slowly, about 5/6 turns and the cutter is through and when It`s cutting you can feel it, so just keep the presser on till it comes out the muzzle. Have just finished the rifling and it looks good on top of the lands, but crap in the groves, the cutter leaves scratch marks in the groves, so in for a bit of lapping and polishing . How it works is when you come out the muzzle, clean out chips, put cutter down, oil, walk to crank end, turn handle back , rifling rod at breech end ,walk to breech end, adjust cutter nut and push in, walk to crank end, crank handle till cutter comes out muzzle, clean chips,!!!!##*@@!, and the book says to do this 50/60 times per grove ,

. I think I could sell this as the super rifling keep fit machine

. I think I could sell this as the super rifling keep fit machine  , the wife says I`m looking like twigge! , Have to have one of my homebrews,

, the wife says I`m looking like twigge! , Have to have one of my homebrews,  , Homebrew.357.

, Homebrew.357.

-

12-11-2014, 05:34 PM #53

@homebrew.357

Have a couple mate .... you've earned them.

Cheers

Pete

-

12-11-2014, 08:31 PM #54

Hi Kotuku, Look , a bit busy at the mo, the army blokes think I`m just the one to knock up a few tanks from A K L`s `s old diesel trains, said I`d give it a go, but would need a few F/P washing machine bits , but had to have a meeting with AK`s stallion, for the trains, but went tit`s up, he was having a meeting with some high school girls. There goes the defence of the country,

, Homebrew.357.

, Homebrew.357.

-

13-11-2014, 05:15 PM #55

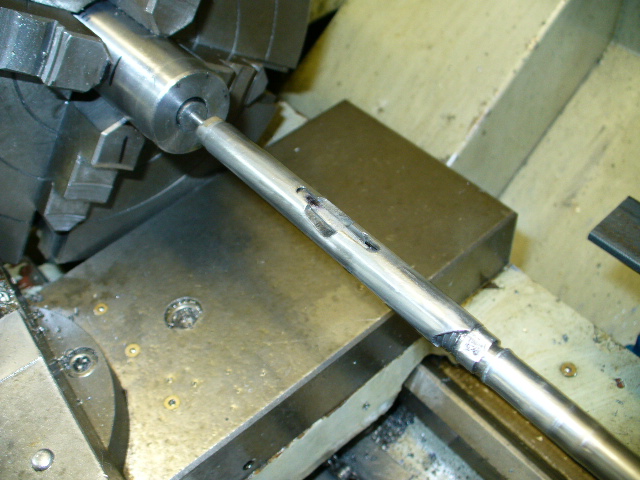

Any way, with all that walking up and down I`v worn out my hugges, well It`s cold in the workshop. I`m not a top shot with a camera , but have a deko at the (rifled bore), now Its not perfect ,but the rifling is there and a bit of lapping, polishing with lots of elbow grease should see it right, It`s only for lead bullets anyway .

, Homebrew.357.

, Homebrew.357.

, Has possibilities .

, Has possibilities . , yep, 1-18" twist, good for 800 yards,

, yep, 1-18" twist, good for 800 yards,

-

14-11-2014, 07:47 AM #56

Ha ha, interesting you should say that, I saw John Brownings rifling setup at the Browning museum in Ogden Utah. It used a wooden rod about 5 foot long, from memory, with a single slow twist thread cut along it, to drive the cutter. He operated it by hand, walking back and forth the 5 or so feet hundreds of times. They reckoned he walked 12 miles or something to rifle each barrel!

10MRT shooters do it 60 times, in two directions and at two speeds.

-

15-11-2014, 12:06 PM #57Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,248

ah homebrew -regardless youre a bloody genius. if ya ale is as good as ya DIY engineering you'd have to be on cloud nine. keep up the great work.

-

15-11-2014, 08:47 PM #58

Hi guys, There`s some scratch marks in the bottom of the groves, cutter marks, so made up a new cutter out of cast iron for the rifling head, it just rubs and with a bit of Ajax and some burnt 600grt paper mixed with oil should polish it up. The top of the lands are nice smooth from the rifling head rubbing, but will still have to lap bore out to .450". This is where you don`t rush it.

, Hombrew.357.

, Hombrew.357.

, Cast iron bore polisher.

, Cast iron bore polisher.

-

18-11-2014, 07:41 PM #59

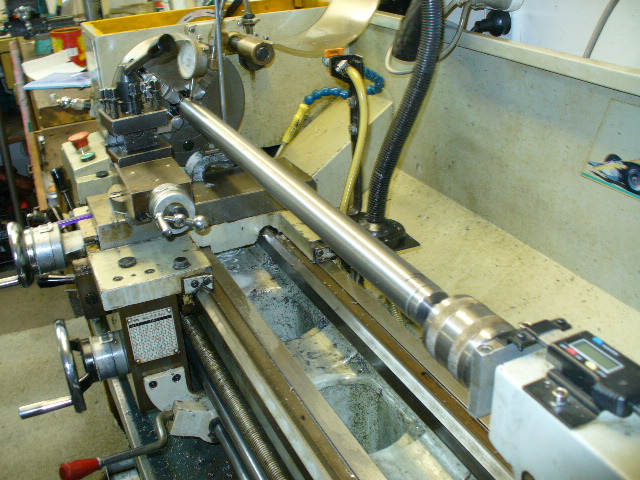

Got the bore out to .450" buy simply using a wooden dowel , cut a slot in one end and slot in a bit of 600 grt paper with a bit of thin plastic for backing, start at breech end, rod held with vice grips and in it goes with plenty of fluid , lathe at fast spin. Up and a few times and clean bore, then tap in lead slug to get size, at .450"-.457" , that will do it. Now have to machine taper the OD, muzzle at 1' and breech 1.130" for receiver . Would like to make it octagonal , so will have look at ways of doing it, could possible grind it, have to have look in my comeinhandy box. Homebrew.357.

, The K I S S way of doing it.

, The K I S S way of doing it.  , Machining muzzle end to 1" for taper setting up.

, Machining muzzle end to 1" for taper setting up.

-

18-11-2014, 07:45 PM #60

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks