Hi Homebrew,

do you think it would be safe to run factory loads in a barrel like yours?

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 76 to 90 of 274

-

11-12-2014, 08:16 PM #76Nothing is tough about having a 70 lb bow and looking like an uncoordinated praying mantis while trying to draw it back.

-

-

12-12-2014, 10:34 PM #77

Hi B F, If the barrel bore was really good should be no problem with a good proof test load. I`m only making barrels on my lathe for black powder loads or equivalent ones in nitro powder and lead bullets only, more forgiving in a rough barrel as mine is no way perfect and will heat treat both barrel and receiver when finished machining. I have the Lyman load data for classic American calibers and all the loads for the 45-70 are for smokeless powder, but keep the max pressure to 28,000 cup. So I will be loading black powder and 405gr bullets and watching the "ouch" bit on my shoulder,

, Homebrew.357.

, Homebrew.357.

-

13-12-2014, 06:43 PM #78

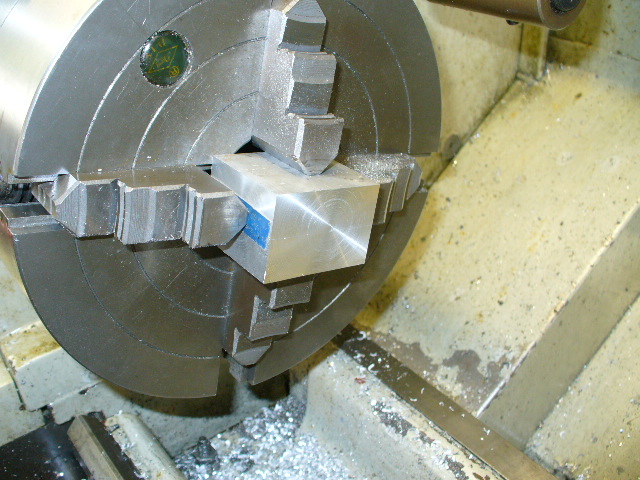

Hell, with all this holy stuff around you need a gas mask on and a knife to cut the air. Speaking of cutting , there`s a pic of some real action cutting the octagonal so you know I`m not pulling your wiser. It getting there, have done 4 sides so far. Homebrew.357.

Hell, with all this holy stuff around you need a gas mask on and a knife to cut the air. Speaking of cutting , there`s a pic of some real action cutting the octagonal so you know I`m not pulling your wiser. It getting there, have done 4 sides so far. Homebrew.357.

, Cutter shaving off a nice curl from the barrel and a pile from a few passes , the trik is to keep the cutter sharp.

, Cutter shaving off a nice curl from the barrel and a pile from a few passes , the trik is to keep the cutter sharp.

-

18-12-2014, 05:00 PM #79Member

- Join Date

- Sep 2013

- Location

- Paremoremo

- Posts

- 66

I am in awe of you! You have done what I have been wanting to do only I only wanted to re-bore shot out 303 barrels to 357. I was thinking of using the feed to drive the rifling cutter at a different speed to the chuck so as to achieve the rifling twist desired. Anyway, I didn't get that far. But you have inspired me and given me some ideas.

Regarding the question of whether your barrel would be safe with factory loads, I would say absolutely.

Are you planning on shooting only naked cast bullets or do you have paper patching in mind? There are folks shooting paper patched 45-70's with stunning accuracy at ridiculous ranges. Think 800 yds with all ten shots in the centre of the gong. The centre is a bit bigger than a tennis ball but still. I'm guessing about a meter diameter, maybe smaller.''Assume everything that moves is a human before identifying as otherwise''

-

20-12-2014, 07:44 PM #80

Hi .303 guy, I suppose there`s a lot of ways of doing this , like a sine ways rifling bar, just have to look on the internet for ideas. I just got lucky with my gearbox and bike bits , and the end result is allways different to what you think, I was going for a twist of 1-18" and through I had it, but no it came out 1-20" so it will have to do. Now the barrel is cut octagonal and stopped short at the breech end so I could grind the tulip bit that the Sharps barrel has at the breech end . Now all I`v got to do is polish and clean her up and at this stage will get it heat treated , but after xmas, I`m having a holiday, cheers, Homebrew.357.

, Octagonal done.

, Octagonal done.  , A raw Sharps Octagonal barrel, hope it shots strait.

, A raw Sharps Octagonal barrel, hope it shots strait.

, Grinding the tulip .

, Grinding the tulip .  , Bit of a polish should help.

, Bit of a polish should help.

Last edited by homebrew.357; 20-12-2014 at 07:49 PM.

-

20-12-2014, 08:36 PM #81

Hey at least with those flats cut on it you can hold it in the vice real good

10MRT shooters do it 60 times, in two directions and at two speeds.

10MRT shooters do it 60 times, in two directions and at two speeds.

-

20-12-2014, 10:08 PM #82

You deserve one.

Real guns start with the number 3 or bigger and make two holes, one in and one out

-

21-12-2014, 05:59 PM #83Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,248

go enjoy your xmas break homebrew ,cause as said hell have you earned it and boy has this been an amazing thread to follow!

-

01-02-2015, 07:36 PM #84

Hi Guys, Hope you had a good xmas and put a dent in the brown ale supply, I need three homebrew kits at least to stock up my supply. Have done a bit more to my Sharps barrel, octagonal finished and have cleaned up the breech end ready for thread cutting, it will be 1.5 metric thread , and have cut the muzzle crown , looking good. The block of 4140 has arrived for the receiver , so will be farming that out for cutting the breech block hole and for something to do I have made a double cavity mould with to ali blocks , weight range, .430/45 I think, won`t know till I do some casting.

Cheers, Homebrew.357.

Cheers, Homebrew.357.

, 4140 block.

, 4140 block.  , breech end tulip.

, breech end tulip.  , ready for thread.

, ready for thread.  , nice crown on muzzle.

, nice crown on muzzle.

, ali blocks for mould.

, ali blocks for mould.  , have to see what thay cast.

, have to see what thay cast.

-

03-02-2015, 07:00 PM #85

Just couldn`t stand the suspense of not knowing what my new mould would cast out at, so had a bit of lead casting today. Results, .463"dia, and the double cavity mould cast one at 425grs, and one at 406grs, so all in all not to bad, now will just have to wait till the Sharps is finished to see how they shoot.

, Carn`t stand the suspense.

, Carn`t stand the suspense. ,Homebrew.357.

,Homebrew.357.

-

06-02-2015, 08:07 PM #86

Don't think we can either

...amitie, respect mutuel et amour...

...amitie, respect mutuel et amour...

...le beau et le bon, cela rime avec Breton!...

-

20-02-2015, 08:18 PM #87

Well you will have to wait guys, I have just got my call up for my final hip op, about six weeks on crutches and sitting around. I know, will look at making a gun cover with bead work on it, Cheers, Homebrew.357.

![Name: 1500x1000rifle-case-beaded-fringe_132[1].jpg

Views: 905

Size: 23.8 KB](https://www.nzhuntingandshooting.co.nz/attachments/f53/34357d1424416983-making-sharps-barrel-my-lathe-1500x1000rifle-case-beaded-fringe_132%5B1%5D.jpg) , Something like this.

, Something like this.

-

21-02-2015, 01:03 AM #88

Hi homebrew.357

I just read your thread on this build on practical machinist-a even better read than this thread.

I look forward to seeing the progress once your back on your feet.

Res

Sent from my iPhone using TapatalkUsing Tapatalk

-

21-02-2015, 07:43 AM #89Member

- Join Date

- Feb 2013

- Location

- spreydon christcurch.

- Posts

- 7,248

all the best with your opHB and hope ya recovery is as just as quick.will be thinkin of ya.

-

22-02-2015, 12:43 PM #90

Hi RES, Yes I have posted this build on two US forums, they couldn`t believe it as well, so the Hawken and the Sharps build is on (Practical machinist and The home machinist forums in the US, you have found me out, but give you some more to read, just look for Homebrew.357 in the gun smithing section. I tell you guys when this hip op is done will be running it in so I can get back in the bush for a hunt, Cheers, Homebrew.357.

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks