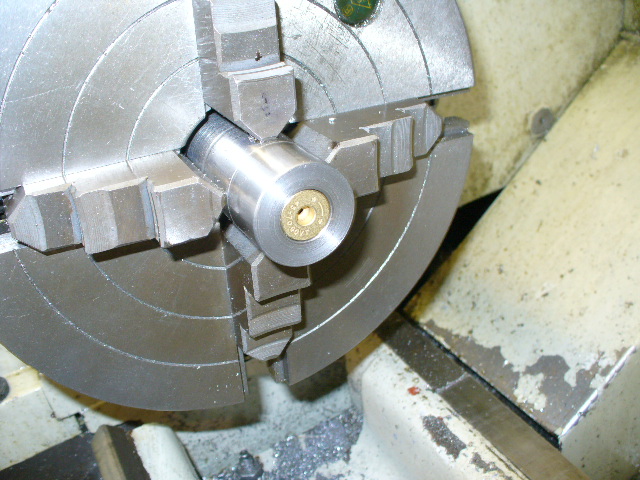

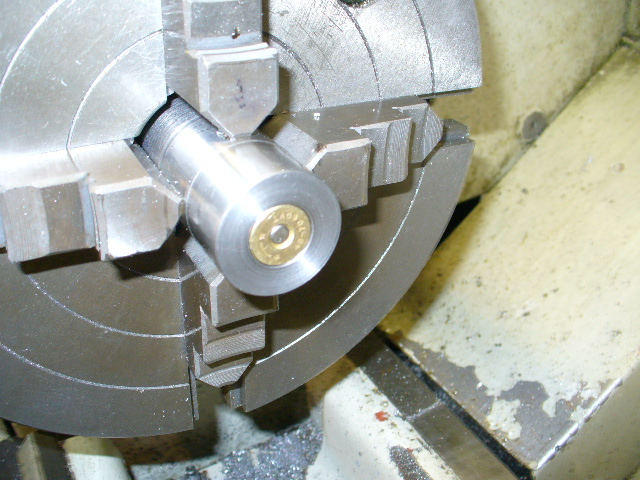

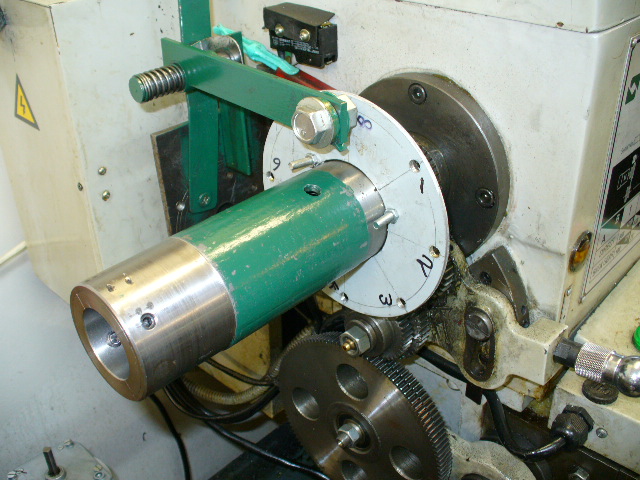

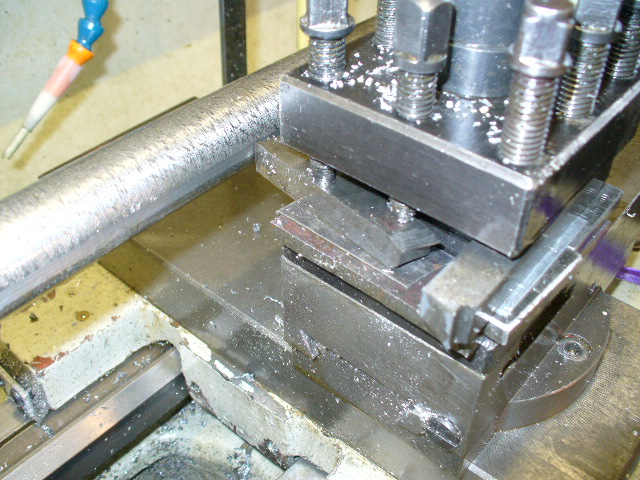

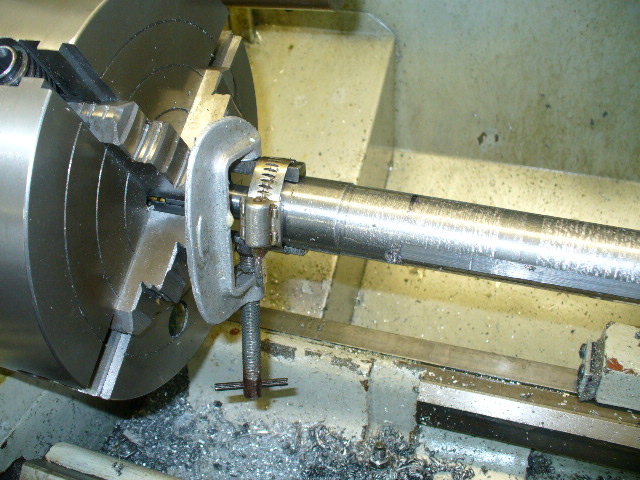

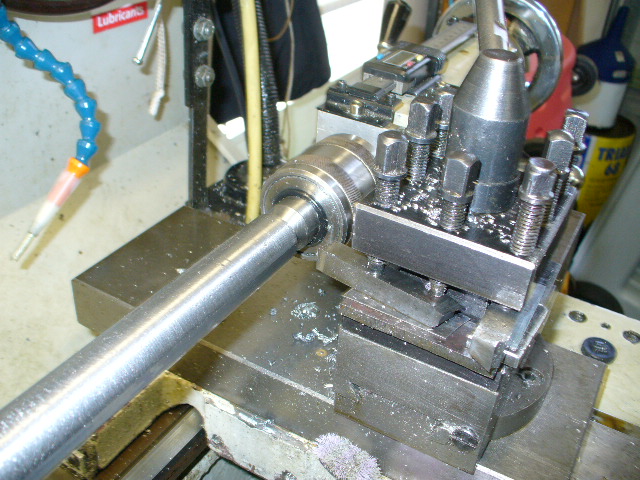

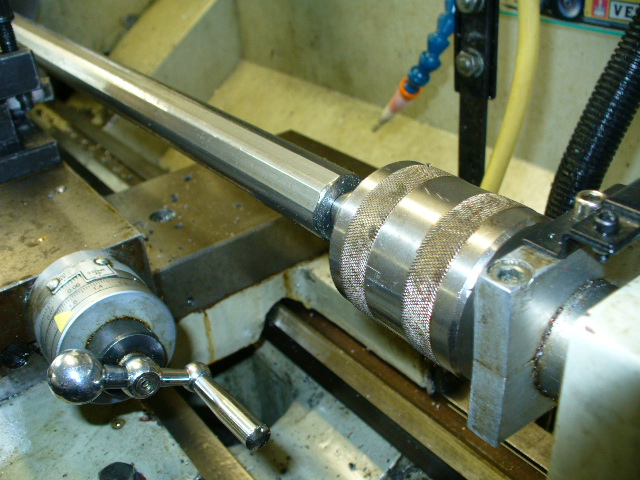

So have set up for turning the O D to 1" at the muzzle and breech at 1.220" for 2" in from the end, this is for the tulip bit that has the receiver threads and then tapers down to 1.150". To set the barrel for taper turning, first the barrel is set to run on centre and the muzzle is turned to size required, 1", set up D T I in tool post and set say 0.04 mm on the breech end, then move to muzzle 1" area and move tailstock over till you get the same setting ,so it will cut strait from 1" back to nothing at 2.5" in from the breech end. The problem with turning a long shaft on the lathe is the middle bit want`s to acted like a wet noodle and chatter like poo, so to stop this I tried a spring on the tool post wrapped around the barrel, seam`s to have stop most of it., Homebrew.357.

, Muzzle turned to 1".

, Breech end set on centre, with drive.

, spring around barrel to stop chatter.

, I diden`t know if it would work, but it did, nice rats tail swarf coming of.

Welcome guest, is this your first visit? Create Account now to join.

Welcome to the NZ Hunting and Shooting Forums.

Search Forums

User Tag List

+ Reply to Thread

Results 61 to 75 of 274

-

20-11-2014, 08:03 PM #61

-

-

20-11-2014, 09:16 PM #62

Nice curls peeling off there HB.

I still am in awe of you making your action parts using your lathe like a mill.

I still am in awe of you making your action parts using your lathe like a mill.

Today I saw gunsmith John Hall's home made rifling machine. Very similar setup with chains and sprockets to what you rigged up on your lathe but his is a dedicated bed.10MRT shooters do it 60 times, in two directions and at two speeds.

-

25-11-2014, 04:40 PM #63

I`m bloody a mazed I even started it, starting to get myself into a corner because of the precision required , so will have the breech block and receiver hole done by a tool maker and as I don`t want to stuff things up, could any body lone me a 45-70 chamber reamer, I know there`s not much of this U S rifle stuff around in NZ, but you never know your luck. A rifle is a precision made tool, so have to get it right. Have to look in E Bay for one and then can sell it to someone else who`s having a go at making a Sharps.

,Homebrew.357.

,Homebrew.357.

-

27-11-2014, 08:52 PM #64

Hi, Have got the barrel sorted, bore, .450" ,lapped, polished with 1200grt paper and O D tapered. Now will have to do some precision work so I don`t stuff things up, which means I`m getting a David Manson finishing chamber reamer for the chamber job , David says it will do the whole job of chambering being a straight case and it will do it 40-50 times, good reamers, he`s in the U S of A. Have ordered a block of 4140 for the receiver and when it comes will sort out getting the breech hole done. But don`t worry there`s plenty of backyard ,number 8 wire stuff to come yet.

,Homebrew.357.

,Homebrew.357.

-

29-11-2014, 08:44 PM #65Member

- Join Date

- Dec 2013

- Posts

- 603

@homebrew.357 stumbled over a web page you might be interested in the other day

Rifling attachment for lathe

-

30-11-2014, 07:59 PM #66

Hi Shamus, Yer, there is a lot of ways of doing the same thing, and that looks good, but I had to work it out with what I had . I`v no mill or dividing head . Have just made a resizing die for the 45-70 cases , the slight tapered case is easy to machine ? and here I am looking for a chamber reamer in the US, it`s a no brainer, Homebrew.357.[ATTACH=CONFIG]31673,/ATTACH] My first reloads in 45-70, there`s are test ones.

-

30-11-2014, 08:42 PM #67Member

- Join Date

- Dec 2013

- Posts

- 603

-

05-12-2014, 08:55 PM #68

Hi, Yep, just set up and have cut the chamber in my Sharps barrel, I used a t/c form cutter for the job with a 6/7 degree slope into the rifling throat and no lead for these old timers. I used a new case and s a a m i 45-70 drawing to get it to a nice fit. The barrel was trued up both ends and light cuts nice and slowly did the job and a polish with 600grt paper I now have a Sharps 45-70 barrel .

, Homebrew.357.

, Homebrew.357.

, Machining case rim recess in barrel.

, Machining case rim recess in barrel.  , chafer sharp edges, done.

, chafer sharp edges, done.  , The gun drill I made, (diden`t work), comeinhandy for this job.

, The gun drill I made, (diden`t work), comeinhandy for this job.  , New 45-70 case fits in snugly .

, New 45-70 case fits in snugly .  , Loaded case fits in nicely .

, Loaded case fits in nicely .

-

09-12-2014, 08:23 PM #69

Hi Guys, Now with a bit of work shop magic I have made my lathe an octagonal one, ( no tit pull Toby), made a ali disc to fit on my rifling register with eight holes for lock pin stop. The barrel is mounted on centres and locked from moving at the four jaw chuck end ,turning one in tail stock. I have set up two cutters at different heights in the tool post, cut using one then turn post for a lower or higher cut with the saddle wheel and just move lock pin around for the next one. Nice light cuts shaves in the flats, esy pesy,

, Homebrew.357.

, Homebrew.357.

, Octagonal, eight holes disc for lock pin.

, Octagonal, eight holes disc for lock pin.  , Two cutters at once for maybe a faster job.

, Two cutters at once for maybe a faster job.

-

10-12-2014, 06:41 PM #70

I imagine you're using the feed mechanism to get a nice uninterrupted pass and not moving the carriage by hand? Doesn't seem to be much you can't do with that lathe...

10MRT shooters do it 60 times, in two directions and at two speeds.

10MRT shooters do it 60 times, in two directions and at two speeds.

-

10-12-2014, 07:40 PM #71

Hi ishoot10s, No such luck mate, carn`t put the lathe in drive with the gear box locket up for cutting the octagonal , so yes I`m winding the saddle up and down, up and down, ext .ext,.

Say one flat takes 50 parses , only cuts from tail stock to chuck, so for eight flats that's 400 down and 400 up, yep I`v got arms like a gorilla , but nothing is easy . , Home brew.357.

, Home brew.357. , barrel clamped at chuck end on centre.

, barrel clamped at chuck end on centre.  , muzzle end in turning centre and tail stock set over to cuts the flats.

, muzzle end in turning centre and tail stock set over to cuts the flats. ,And the octagonal is SLOWLY coming on.

,And the octagonal is SLOWLY coming on.

-

10-12-2014, 08:10 PM #72

Holy shit!

10MRT shooters do it 60 times, in two directions and at two speeds.

-

10-12-2014, 08:45 PM #73

I just get more and more impressed as this project progresses

Using Tapatalk

-

10-12-2014, 10:39 PM #74Member

- Join Date

- Mar 2014

- Location

- Tauranga

- Posts

- 3,036

Skills

-

11-12-2014, 11:11 AM #75

Similar Threads

-

Making A Quigley Sharps Rifle on my lathe.

By homebrew.357 in forum Projects and Home BuildsReplies: 58Last Post: 26-09-2014, 08:58 PM -

Anyone got a lathe at home

By specweapon in forum Projects and Home BuildsReplies: 12Last Post: 14-07-2014, 09:55 PM -

Is there anyone in Dunedin that can drive a lathe?

By gimp in forum Firearms, Optics and AccessoriesReplies: 20Last Post: 19-02-2012, 06:34 AM

Tags for this Thread

Welcome to NZ Hunting and Shooting Forums! We see you're new here, or arn't logged in. Create an account, and Login for full access including our FREE BUY and SELL section Register NOW!!

419Likes

419Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks